LCX

RG66010687_rev.00

39

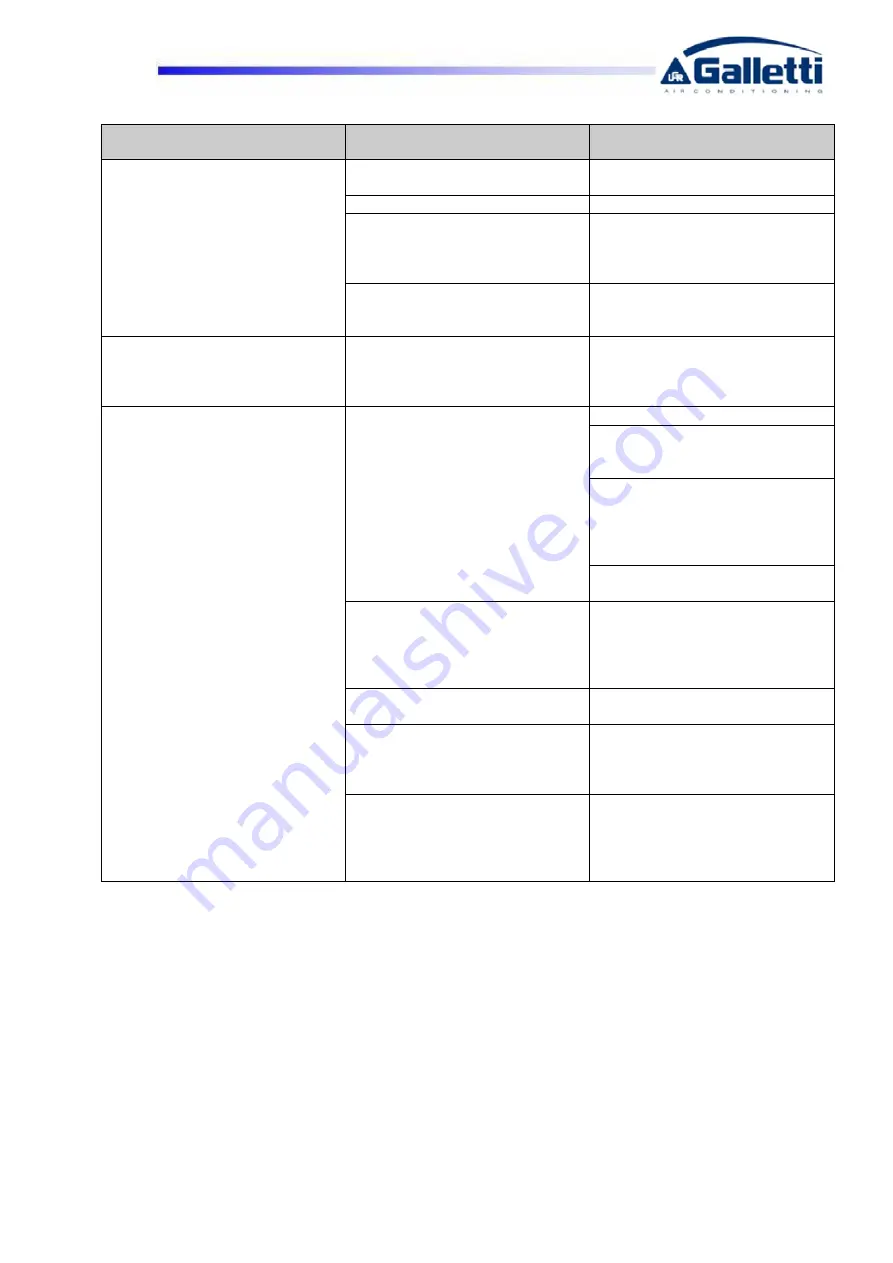

FAULT

Analysis of possible causes

Corrective action

The unit does not start.

No electrical power supply.

Check its presence both on the

primary and auxiliary circuit.

The circuit board is not powered.

Check the protections.

There are alarms present.

Check the microprocessor panel

for the presence of alarms,

eliminate their cause and restart

the unit.

Incorrect

phase

sequence.

Invert the two primary power

supply phases after having

isolated the unit upstream.

The compressor is noisy.

The compressor is not turning in

the right direction.

Check the phase sequence relay.

Invert the phases on the terminal

board after having isolated the unit

and contact the manufacturer.

Presence of abnormally high

pressure.

Insufficient air flow rate to

condenser.

Check that all fans turn correctly.

Check the condenser air inlet T

and prevent recirculation from

being formed.

Check that the effective voltage

RMS to the fans is the maximum.

Check the pilot pressure

transducers of the rev. regulator

[optional].

Make sure the finned coils are

clean.

Presence of air in circuit, detected

by the presence of air bubbles on

the flow indicator even with sub-

cooling values above 5°C.

Drain and pressurise the circuit

and check for leaks. Execute a

slow emptying [greater than 3

hours] until the value of 15 Pa and

then recharge in liquid phase.

Unit too loaded detectable by sub-

cooling greater than 8 °C.

Discharge circuit.

Thermostat valve and /or filter

clogged. These aspects are also

present with low pressure faults.

Check the temperatures upstream

and downstream from the valve

and filter and replace them if

necessary.

Insufficient water flow rate if heat

pump is operating.

Check the load loss of the

hydraulic circuit and/or the correct

functioning [rotation direction] of

the pump. Check the outlet water T

and make sure it is 45°C or less.