LCX

RG66010687_rev.00

40

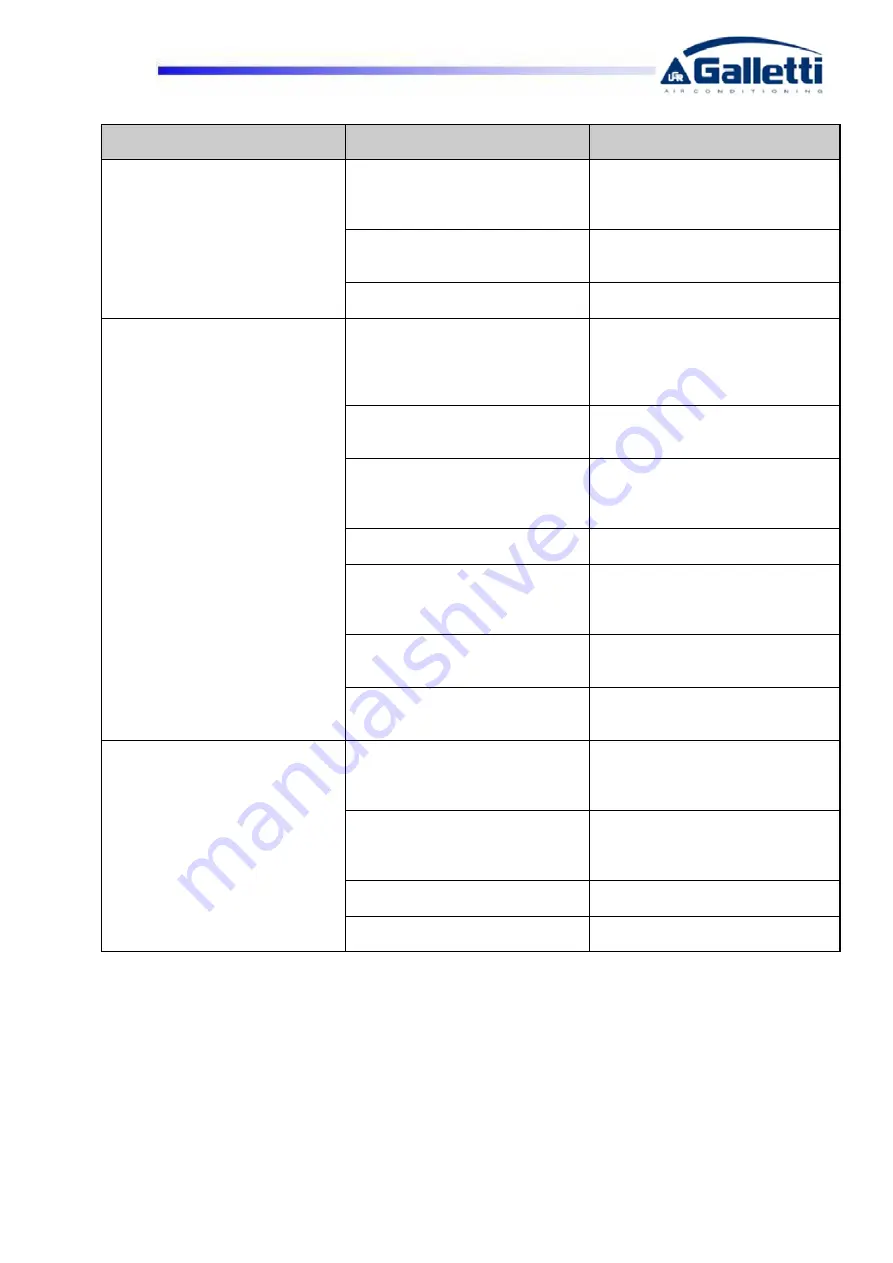

FAULT

Analysis of possible causes

Corrective action

Low condensation pressure.

Faulty

transducers.

Check the transducers and the

efficiency of the needle pusher on

the schrader valves they are

connected to.

Too low outside T and/or presence

of strong winds.

Mount the condensation control and

/or protect the unit from prevailing

winds.

Low water T if heat pump is

operating.

Check whether the thermal load is

compatible with the unit’s potential.

Low evaporation pressure.

Low water flow rate.

Check the correct rotation of the

pumps. Check for load losses on

the hydraulic circuit. Make sure the

one-way valve of the pump unit is

sealed (optional).

Malfunctioning of thermostat valve. Heating the bulb by hand, check the

opening and adjust it if needed. If

there is not response, replace it.

Clogged

filter.

Pressure drops upstream and

downstream from the filter should

not exceed 2°C. If they do, replace

the filter.

Low condensation T.

Make sure the condensation control

works properly [if present].

Low

refrigerant

load.

Check the refrigerant level by

measuring the degree of

subcooling; if it is below 2°C top up

the unit.

Coil frosted if heat pump is

operating.

Check the correct defrost

parameter settings. Make sure the

4-way valve works properly.

Low outside T if heat pump is

operating.

Check compliance with the

operating limits and eliminate any

bypasses and back flow of air.

The compressor does not start.

Internal thermal protector tripped.

For models equipped with

protection modules, check the

status of the thermal contact. Find

the causes after restarting.

Intervention of circuit breakers or

fuses in line after short circuit.

Check the cause by measuring the

resistance of the individual coils

and the isolation towards the

chassis before powering.

Intervention of HP or LP switches.

Check the microprocessor,

eliminate the causes.

The phases in the distribution

cabin have been inverted.

Check the phase sequence relay.