2

UT66000806 - 02

UTN

All copying, even partial, of this manual is strictly forbidden

The technical and dimensional data indicated in this catalougue are subject to modifications

in the view of the improvement of the product.

1

MEAN FEATURES

The new range of UTN high pressure fan coils units has been designed for

conditioning rooms that require the installation of ducted units.

Proposed in 12 models with air flows from 600 to 3000 m3/h, the UTN units

are characterized by a wide applicative flexibility thanks to the special

constructive solutions.

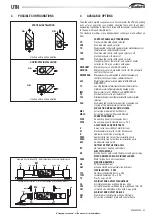

> possibility of installation both in horizontal and vertical position thanks

to the special conformation of the condensate discharge system;

> the air intake direction may be modified during installation;

> reduced height (280 mm up to model 16A);

> pre-shared element for the recycle of external air, standard on all models

(

Φ

100 mm);

> wide range of accessories for effectively.

INDEX

1

Main features ............................................................................... pag. 2

2

Versions and components ............................................................. pag. 2

3

POSSIBLE CONFIGURATIONS ....................................................... pag. 3

4

Available options .......................................................................... pag. 3

5

Rated technical data ..................................................................... pag. 4

6

Ventilation features ................................................................. pagg. 5 / 6

6.1

Accessories: air pressure drop .................................................

pagg. 7 / 8

6.2

Sound power levels for octave band ...............................................

pag. 8

7

Performances ...................................................................................

7.1

Cooling capacity .................................................................... pagg. 9 / 10

7.2

Heating capacity ................................................................. pagg. 11 / 12

7.3

DF coil heating capacity ............................................................... pag. 13

8

Installation suggestions ............................................................... pag.14

9

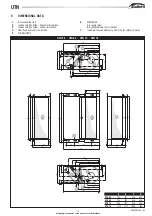

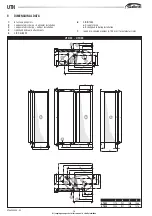

Dimensional data ................................................................ pagg. 15 / 16

10

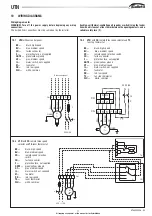

Wiring diagrams .................................................................. pagg. 17 / 23

10.1

Motors electrical data ..................................................................

pag. 24

11

Accessories ........................................................................ pagg. 24 / 27

12

Maintenance ............................................................................... pag. 28

DECLARATION OF CONFORMITY

Galletti S.p.A. with head offices in Via Romagnoli 12/A, 40100

Bentivoglio (Bologna) - Italy, declares under its own exclusive

responsibility that the UTN range of air conditioning and hot-air

heating units, heating and conditioning equipment, for systems

that distribute air through channels, comply with the requirements

of the following EEC Directives:

73/23, 89/392, 91/368, 93/44, 93/68, 98/37 and 89/336.

Bologna, 02/07/2001

Luigi Galletti

Chairman

OPERATING LIMITS

Thermal carrier: water

Water temperature: + 5°C to +95°C

Air temperature: -20°C to + 43°C

Power supply voltage: 230 V +/-10 %

Max. pressure of primary fluid: 10 bar

2

VERSIONS AND COMPONENTS

Versions

UTN

air handling unit setup for 2-pipe systems

UTNDF

air handling unit setup for 4-pipe systems (2 heat

exchangers)

N.B. both version may be manufactured, on request, with pre-painted

panels.

Components

>

Load-bearing structure made of galvanized steel sheet of suitable

thickness, duly insulated with noise-proof/anticondensing material,

self-estinguishing in Class 1; the insulating material is characterized

by a thickness of 10 mm and a density of 90 Kg/m

3

.

The unit is completed by the following:

- inspections panels;

- setup for external air intake;

- fast-coupling slots.

>

Dual intake centrifugal fans made of alluminium, with statically and

dinamically balanced impellers, coupled directly to the electric

motor.

>

3 speed electric motor, equipped with permanently fit condenser and

thermal safety device, installed on vibrator damping supports.

>

Heat exchanger: high efficiency, made of copper tube and alluminium

fins secured to the tubes by mechanical expansion. It is fitted with

brass manifolds and air valves. The heat exchanger, normally

supplied with left hand attachments, may be turned by 180°.

>

System for collecting and discharging condensate setup either for

horizontal or vertical installation.

>

Terminal strip for fast - on electrical connections.