20

Figure 20

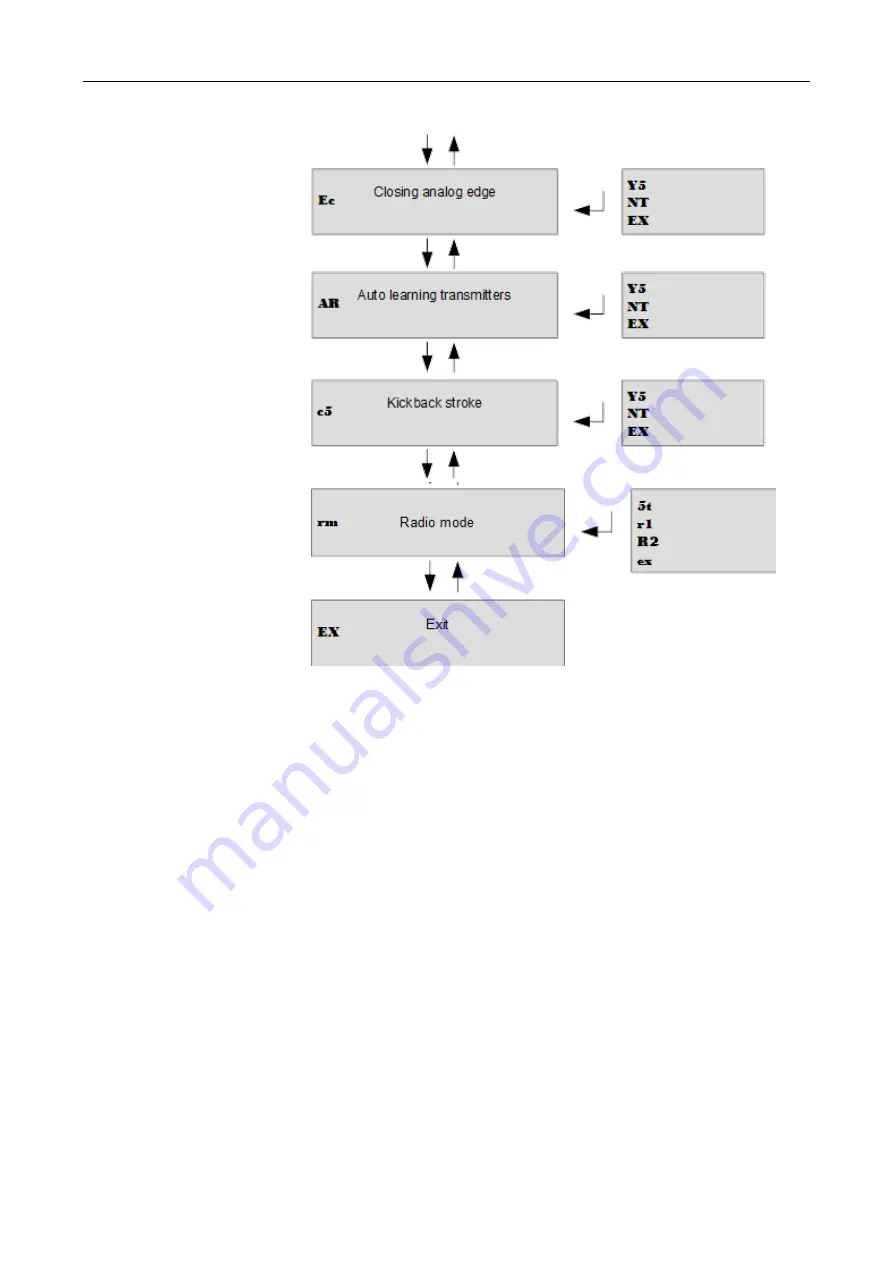

Advanced menu

TM working times menu:

In this menu it

’s possible to modify working times of control unit:

T1- Working time motor1

51- Start time slowdown motor1

T2- Working time motor2

52- Start time slowdown motor2

DO-Motors delay opening

DC- Motors delay closing

TL-Electric lock activation menu.

EX-Exits from advanced menu.

Once selected working times to be changed, use up/down to modify it from 0 to 99 seconds. Push

enter to confirm.

To exit without modifications select EH or push together up and down.

5G Single wing mode:

In this menu it

’s possible to verify or set if gate works in single wing mode (motor2).Use up/down to

choose yes (YS), not (NT) or exit(EX). Push enter to confirm.