28

MAINTENANCE & ADJUSTMENTS

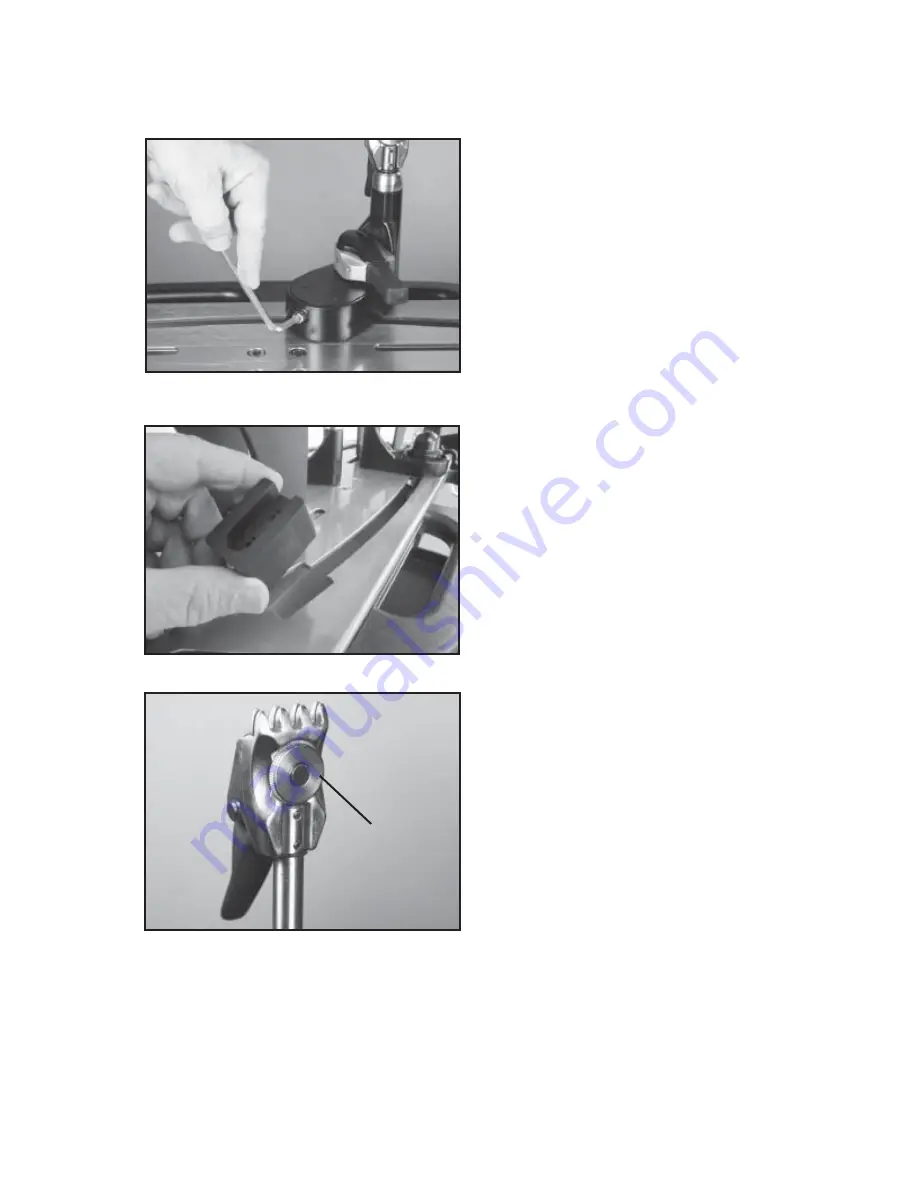

Clamp Base Removal

Clamp Bases can be removed from the

Turntable for maintenance or cleaning by

removing the Clamp Stop located at the end

of the slot in the Turntable. To remove the

Clamp Stop, remove the two screws holding

the Clamp Stop in place from the underside of

the Turntable. Lift the Clamp Stop out of the

slot, slide the Clamp Base to the end of the

slot and lift it out. Replace the Clamp Base

and clamp stop in reverse order.

Adjusting String Clamp Jaw Spacing

The String Clamps will need minor adjust-

ments according to what string type, construc-

tion, and gauge you are using. To adjust the

gap (clamping pressure) between the clamp

jaws, insert the string through the racquet

as if you were beginning the main strings.

Clamp the strings and pull tension. If the

string slips through the jaws of the clamp,

tighten the clamp by turning the Adjustment

Knob, in the clockwise direction. If the clamp

leaves impressions in the string, it may be

excessively tight and should be adjusted by

turning the Adjustment Knob counter clockwise to increase the gap between the jaws.

NOTE: Due to the bearings used in the clamp lever the action of the clamp lever is very

light making it easy to apply excessive clamping pressure. Clamps that are set too tight

can damage the string as well as the string clamp jaws.

The clamp jaws should be cleaned periodically to be free from dirt, oil, and any residual string

coating for them to grip properly. The cleaning stone supplied with the machine is excellent

for removing build-up on the diamond coated surfaces. Rub the gripping surfaces with the

cleaning stone and remove any residual dust with a brush or cloth and isopropyl alcohol.

Adjustment

Knob

Auto-Release Clamp Base Adjust-

ment

If the Clamp Bases slip on the Turntable,

the base locking levers may need adjusted.

Turn the cap screw located on the end of the

Clamp Base clockwise to increase clamping

pressure and counterclockwise to reduce it.

If frequent adjustment is needed, try loos-

ening the Locking Lever Adjustment Screw

and tighten the two screws located on the

underside of the Clamp Base. Re-tighten

the Locking Lever Adjustment Screw and

adjust as needed.