6

TENSIONER CONTROLS

Setting Tension

The Progression 600ES stringing machine utilizes a rotary adjusting knob along with a digital

L.E.D. display to indicate the set tension. To set the tension, rotate the adjustment knob

clockwise to decrease the displayed tension, counter-clockwise to increase the displayed

tension, until the desired tension is displayed on the digital display. Aramid fiber and Metallic

strings will generally string up tighter on the Progression Es machine compared to synthetic

or natural gut strings. Therefore, when stringing with Aramid (Kevlar, Technora) hybrid strings

or metallic strings, we recommend setting tension 4-5 lbs. lower than you would normally use

for synthetic or natural gut strings.

C

D

B

A

C

D

E

B

A

F

G

8 8 . 8

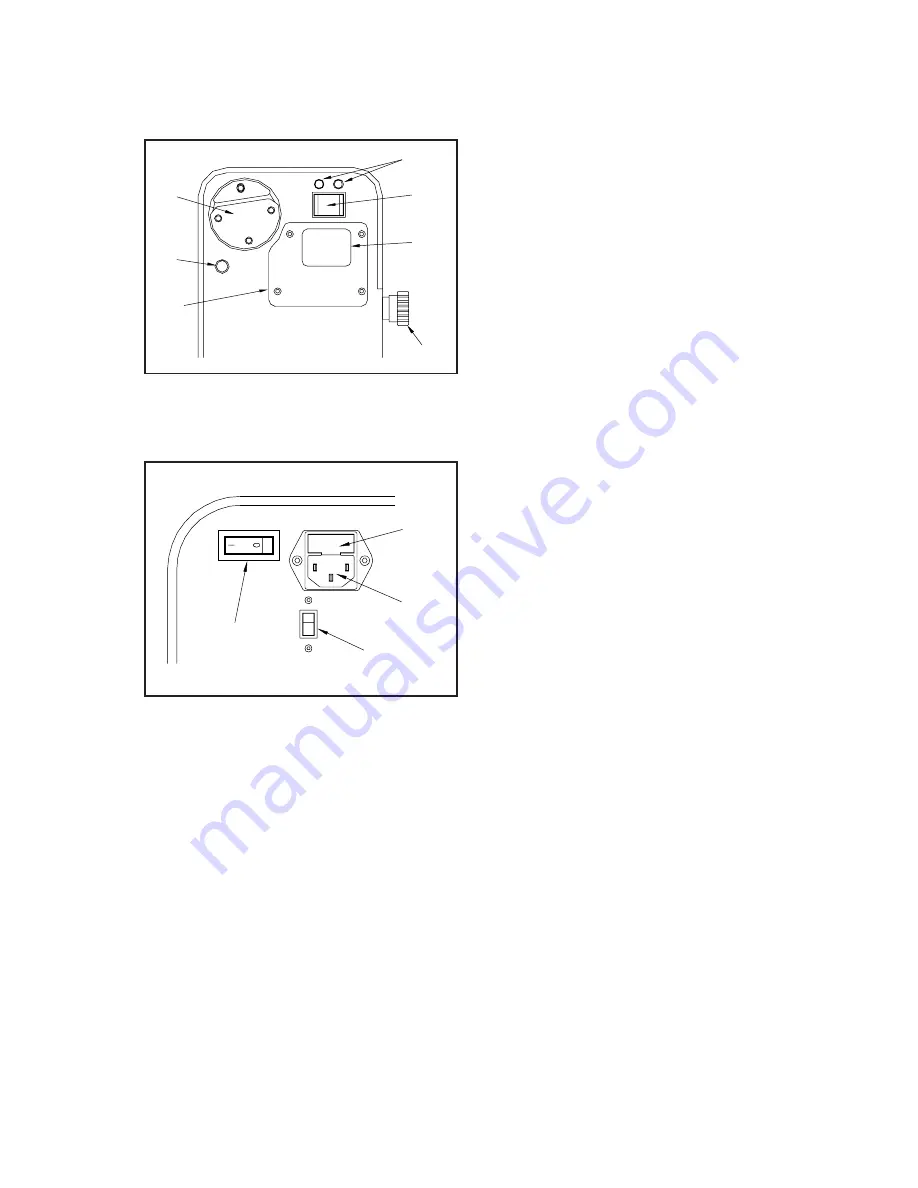

Front Panel Features

A -

String Gripper

B -

Indicator lights

C - Tension Switch

D - L.E.D. Tension Display

E -

Tension Adjustment Knob

F -

Cover Plate

G - Gripper Reversing Switch

Rear Panel Features

A -

Lighted Power Switch

To turn the power on, press the top half

of the switch.

B -

5 Amp Fuse Holder (w/ spare fuse)

C - A/C Power Cord Socket

Insert the female end of the power cord

into the socket.

D - 110V / 220V Select Switch

Summary of Contents for PROGRESSION 600ES-LED

Page 15: ...14 EXPLODEDPARTSVIEW ...