8

Pulling Tension

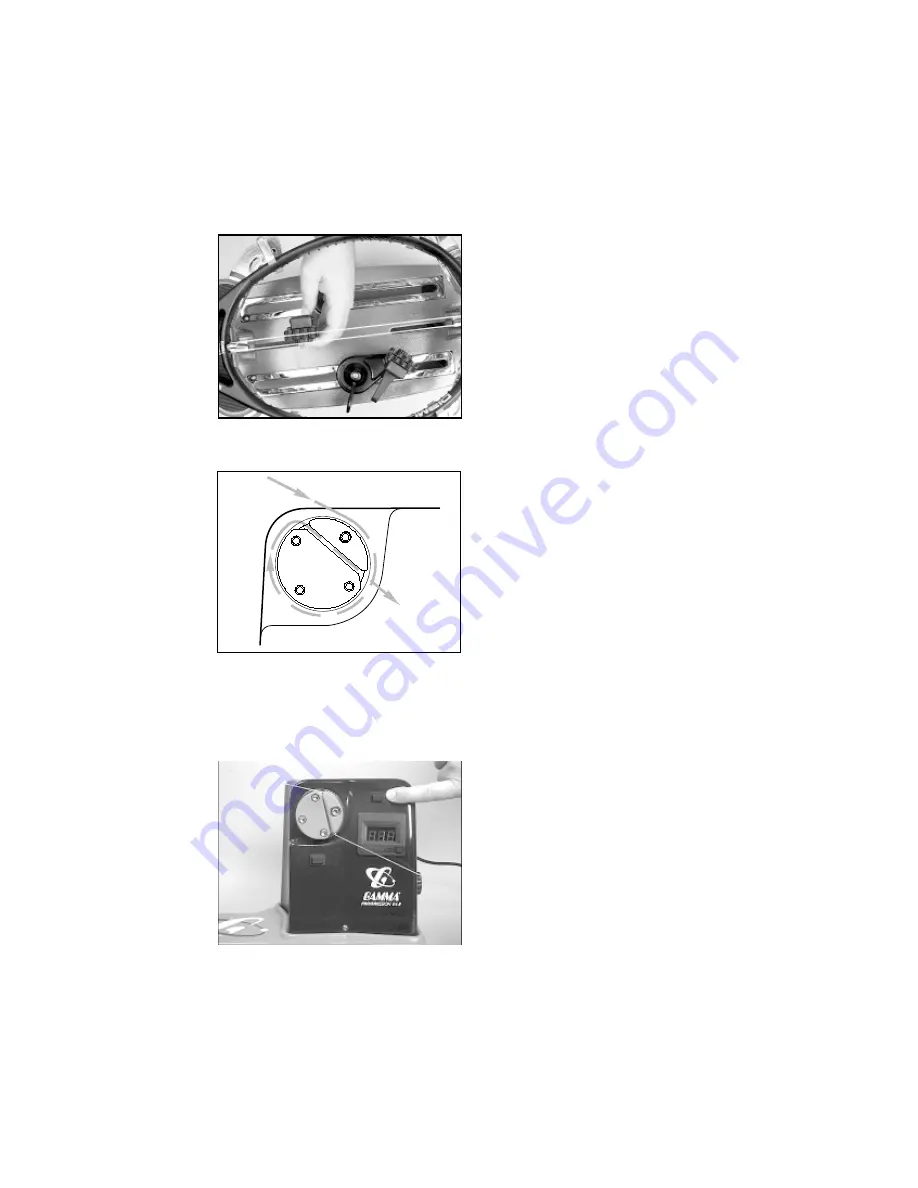

To pull tension, wrap the free string clock-

wise around the gripper drum and position

the string between the gripper jaws.

The string must pass over the top half of the

gripper before being placed between the

gripper jaws, as the tension on the string

provides the clamping force to the gripper

jaws.

Gently pull the string until all slack is re-

moved.

STRINGING THE FRAME

Clamping the First Main String

To begin stringing the main strings, thread

the two ends of the string through the two

center holes at the appropriate end of the

frame and continue through the opposite

center holes. Thread one end of the string

through the adjacent grommet hole and pull

excess by hand.

Secure one of the strings using a string

clamp.

To tension a string, push the tension switch

or the foot pedal. The string gripper will

rotate and slowly apply tension to the

string. When the set tension has been

attained, the gripper will stop rotating. As

the tensioned string stretches, the gripper

may rotate intermittently, maintaining the

set tension.

To release the string after clamping, push

the tension switch or foot pedal. If the string

gripper does not release the string, de-

press and hold the Gripper Reversing Switch

once to release the string.

WARNING:

KEEP FINGERS AWAY FROM GRIPPER

DRUM WHILE TENSIONING STRING. PUSH GRIPPER

REVERSING SWITCH IN CASE OF EMERGENCY.

Summary of Contents for Progression ES II+

Page 16: ...15 EXPLODED PARTS VIEW...