I

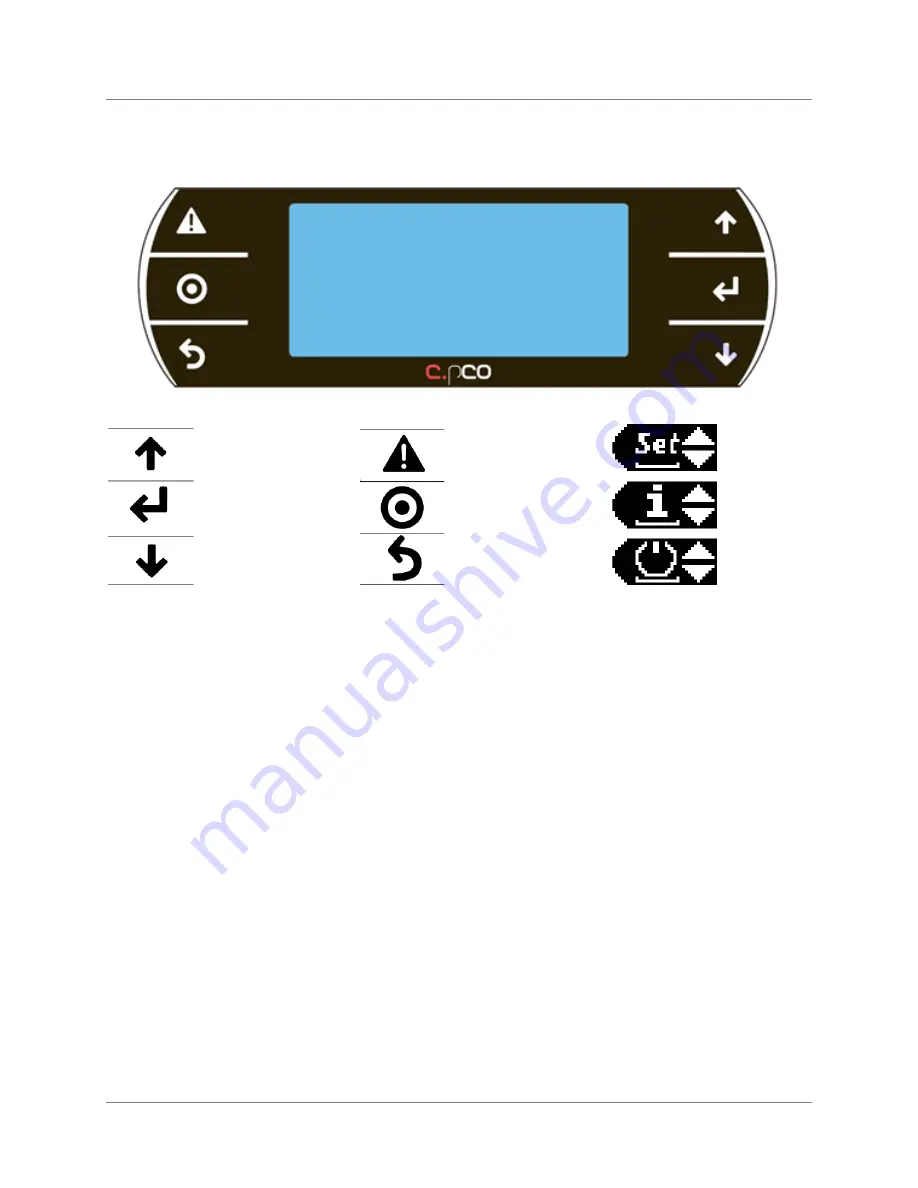

CONTROLLER AND NAVIGATION

:ENTER

:DOWN

:

ALARM

:PROGRAM

:ESCAPE

:SET

:INFO

:POWER

Set Screens:

1.

Glycol set point: Ensure you see SET in the display screen.

a.

You can change options from SET, INFO and POWER by using the UP and DOWN

buttons.

b.

Press ENTER to navigate to the glycol temperature set screen.

c.

Press ENTER again to navigate to the numerical readout. Use UP and DOWN buttons to

adjust to desired setpoint.

2.

Pump pressure set point: Ensure you see SET in the display

screen

.

a.

Press

DOWN

until you see pump pressure set point.

b.

Press ENTER button to navigate to numerical readout and adjust with UP and DOWN to

set pump pressure. Please note that pressure setpoints are often preset.

Info screens:

1. Ensure you see INFO in the bottom right portion of the display screen.

2. Press ENTER to navigate to the first of nine information screens.

3. Use DOWN to scroll through the information screens.

Alarms:

1. Press ALARM.

2. Navigate with UP and DOWN to see current alarms.

a. To clear the alarms, press UP or DOWN through alarm screen until you see a prompt

saying “press Alarm button for 3 seconds.”

:

UP