INSTALLATION GUIDE • USER MANUAL

VERTICAL AIR SERIES

2

5

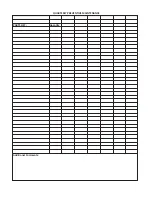

COMPRESSOR NAMEPLATE

The compressor nameplate provides the following information:

•

Unit model and size descriptor

•

Unit serial number

•

Identifies unit electrical

COMPRESSOR INFORMATION

OIL LEVEL

To check compressor oil level, refer to the label near the compressor sight glass. The compressor(s) must be off. Wait

three minutes. Compressor oil level should be within the range indicated on the sticker; close to half full. When

adding oil, always use a fresh can of POE 32 or POE 68 per the compressor data plate.

NOTICE:

Never reuse oil or use oil from an unsealed container.

OIL TESTING

Use the oil test kit provided or recommended by the testing laboratory. Note that the POE oil used in this product is

very hygroscopic and easily absorbs and retains moisture. The acceptable moisture content is less than 100 ppm and

acceptable acid level is less than 0.5 TAN. Note that refrigerant and moisture is very difficult to remove from this oil

using vacuum. Also note that once the seal on a container of POE oil is opened, the oil must be used. Any unused oil

should be discarded.

In the event of a compressor failure, always test the oil with an acid test kit and determine whether the compressor

failure was mechanical or electrical. This is important because it dictates correct cleanup procedure.

COMPRESSOR OPERATIONAL PUMP DOWN

The operational pump down is used to manage the refrigerant charge and prevent liquid slugging into the

compressors, oil dilution and oil starvation. The pump down occurs during all normal shut- down conditions. The

electronic expansion valve will close.

The operational pump down sequence will end when the suction pressure drops below the operational pump down

set point.

ELECTRICAL COMPRESSOR FAILURE

Replace the failed compressor and add a suction filter with cleanup cores and change the liquid line filter drier.

Change filters and oil until the oil no longer tests acidic. See "Oil Testing."

COMPRESSOR MOTOR MEGGING

Motor megging determines the electrical integrity of the compressor motor winding insulation. Use a 500-volt

megger. A less than 1 meg-ohm reading is acceptable and 1000 ohms per nameplate volts is required to safely start

the compressor.

COMPRESSOR CURRENT IMBALANCE

Normal current imbalance could be 4 to 15 percent with balanced voltage due to motor design. Each phase should

register 0.3 to 1.0 ohms and each phase should be within 7 percent of the other two phases. Phase to ground

resistance must be infinity.

NOTICE:

Maximum allowable voltage imbalance is 2 percent.

G&D CHILLERS, INC.

•

GD-VA-R2022C