INSTALLATION GUIDE • USER MANUAL

VERTICAL AIR SERIES

31

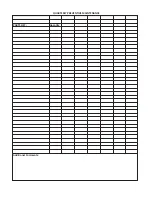

Clean the condenser coils. Refer to "Coil Cleaning" in this manual. Please refer to preventative maintenance (next

page) for items to verify the chiller is in perfect working order. Note that the fields highlighted in yellow are things

the owner/operator can perform. All other fields should be filled out by a licensed technician. Feel free to send the

completed form to

for review to ensure your chiller is to factory spec.

WARNING:

Position all electrical disconnects in the "OPEN" position and lock them to prevent injury of death due

to electrical shock or moving parts.

Clean the condenser fans. Check the fan assemblies for proper clearance in the fan shroud openings and for motor

shaft misalignment or abnormal end-play, vibration and noise.

CONDENSER MAINTENANCE

Clean the condenser coils at least once a year or more frequently if the unit is in a "dirty" environment. A clean

condenser coil will help to maintain chiller operating efficiency.

Follow the detergent manufacturer's instructions to avoid damaging the condenser coils.

To clean the condenser coils, use a soft brush and a sprayer such as a garden pump type or a high- pressure type. A

high-quality detergent is recommended.

Note: If detergent mixture is strongly alkaline (pH value greater than 8.5, an inhibitor must be added).

EVAPORATOR MAINTENANCE

G&D liquid chillers use brazed plate heat exchanger (BPHX) evaporators with factory-installed electronic flow switch

that is positioned in the evaporator fluid outlet pipe.

Note: Strainer maintenance is critical to proper operation and reliability. Any particles larger than 1mm entering the

BPHX evaporator may cause the evaporator to fail, requiring replacement.

The BPHX evaporator is difficult to clean should it become plugged with debris.

Indications of a plugged evaporator include "wet" suction due to lack of heat exchange, loss of superheat control,

depressed discharge superheat (superheat less than 63°F), compressor oil dilution and/or starvation and premature

compressor failure.

EVAPORATOR REPLACEMENT

If the evaporator requires replacement, it is very important that the new evaporator be replaced correctly and with

the correct refrigerant and fluid piping connections. The refrigerant inlet/liquid connection is at the bottom of the

evaporator and the refrigerant outlet/suction connection is at the top of the evaporator and both are on the same

side. Avoid cross-circuiting when installing the new evaporator.

WATER STRAINER MAINTENANCE

The field-installed strainer should be equipped with a blowdown valve. The strainer shall be 20 mesh or higher. For

maximum efficiency, a differential pressure gauge installed across the inlet and outlet will indicate pressure loss due

to clogging and may be used as a guide to determine when cleaning is required. Normally when differential pressure

reaches 5-1Opsi, the screen must be cleaned. To clean open the blowdown valve, and flush out until evacuation is

complete.

G&D CHILLERS, INC.

•

GD-VA-R2022C