3

7

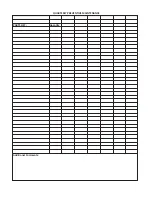

TROUBLESHOOTING

COMPLAINT

SYMPTOMS

CAUSE

SOLUTION

7 Compressor does

not pump

Minimal difference in pressure

between high side and low side

of system, when compressor

motor has power

Broken suction valves

Change compressor

Broken discharge line

Change compressor

Internal pressure safety

valve stuck open

Check item 13 and change

compressor if

necessary

8 Compressor will

not start

Blown fuse or open disconnect

Short circuit or other

electrical failure

Check electrical circuit

and wiring

Tripped or damaged overload

Overheating or overcurrent Wait 2-3 hours for overload

to reset and check

refrigerant charge or power

quality to the compressor

Open pressure switch

Loss of refrigerant

charge

Check for leaks, repair

and recharge

Loose wires

Vibration, bad crimping or

under-torque

Check terminals at

compressor, contactor and

wiring in general

Motor seized

Low oil level or phase

reversal

Check oil level. Restart 3-ph

compressor by switching

2 phases; replace if it does not

restart

9 Compressor starts

but start relay does

not drop out

High running current,

overload trips

Incorrect wiring of start

components

Check wiring

Incorrect or defective

start relay

Confirm operation, model

and make

Incorrect or defective start

capacitor

Confirm integrity and

specs, check if fitted with

discharge resistance

Incorrect or defective

run capacitor

Confirm integrity and

specs

Low voltage

Fix undervoltage protection

10 Compressor

runs but cuts

out on

overload

Internal overload tripping

MUST WAIT 2-3 HOURS TO

CHECK IF IT WILL RESET

Excessive head pressure

due to dirty condenser

or lack of condenser air

or water flow

See item 2 above

Low voltage or unbalanced Fix undervoltage protection

Faulty electrical connections

causing single phasing or

high current surges

Remake the connections

Sticking start relay on

single phase machines

leaving start cap on circuit

Replace relay and ensure start

cap is fitted with a discharge

resistance

I

INSTALLATION GUIDE • USER MANUAL

VERTICAL AIR SERIES

G&D CHILLERS, INC.

•

GD-VA-R2022C