5

www.gantner.com

Valid from June 10th, 2015 • Technical data subject to modification without notice!

DB_GAT-ECOSide-Lock7000--EN_11.indd • Part No. 642832

9. Attach the front label (11) onto the label carrier.

Attention:

If a custom label design is used, ensure that a transparent

field for the status LED (7) is included in the label design.

10. Test the locker door to confirm that it can close easily and the door

shackle inserts correctly into the GAT ECO.Side Lock 7000.

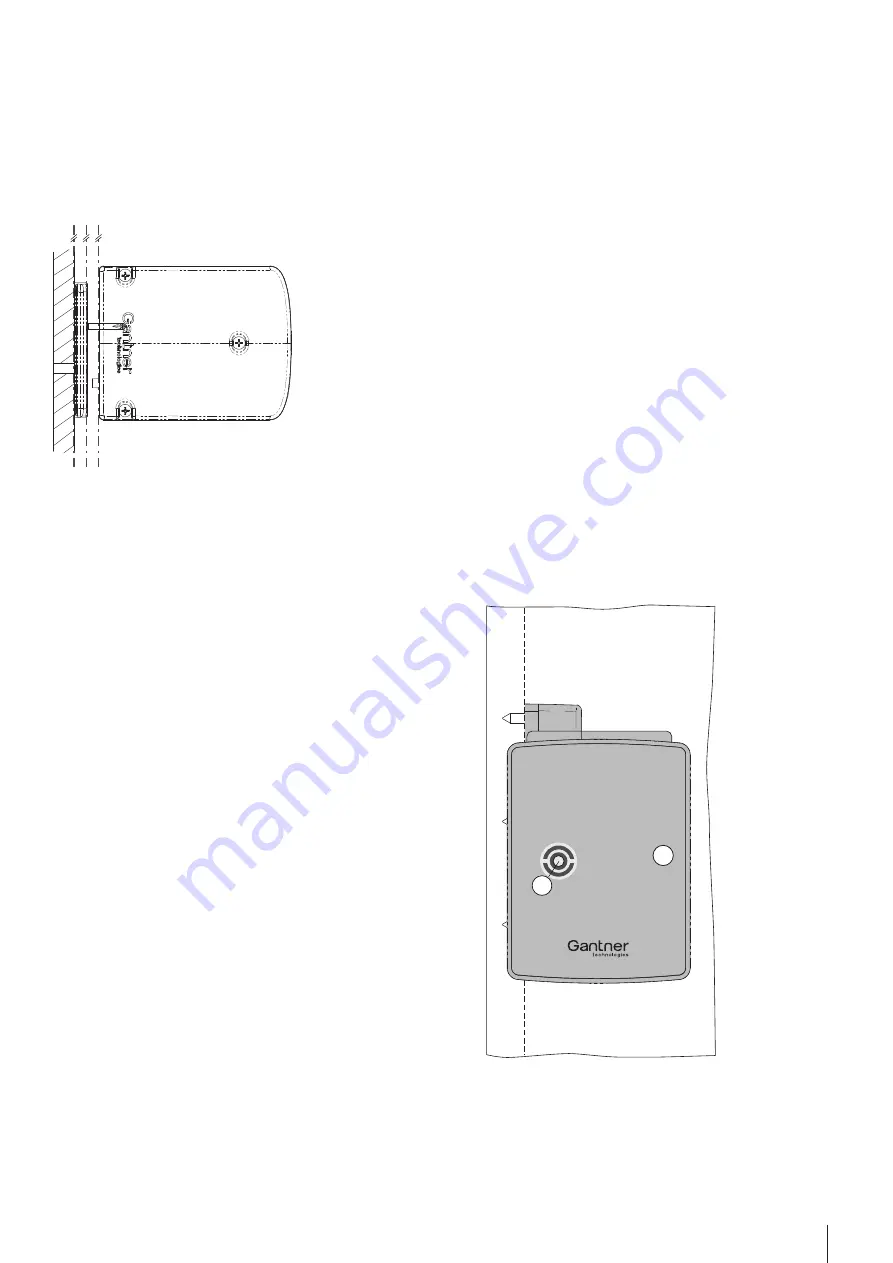

2

2

6

7

1

6

9

6

6

10

7

123

11

7

5

1

Loc

ker wall

50 mm (1.9´´)

6 mm (0.24´´)

94 mm (3.7´´)

Loc

ker door (outside wall)

Loc

ker door (inside wall)

74 mm (2.91´´)

17 mm (0.67´´)

min. 18 mm (0.71´´)

max. 26 mm (1.02´´)

Inside of locker

Locker door

(Front view without label carrier)

Locker door

(Front view with label carrier)

15.1 mm (0.59´´)

32.6 mm (1.28´´)

Loc

ker wall

Locker door

(Front view with label carrier)

L

oc

ker wall

3

3

17

.4 mm

(0.6

8´´)

3

3

3

3

Installation requirements for GAT ECO.Side Lock 7000 and bolt set

Please pay particular attention to the following points:

- The thickness of the locker door must be between 18 and 26 mm

(0.71´´ and 1.02´´).

- When the locker door is pressed shut, ensure there is no gap between

the bolt set (2) and the front of the GAT ECO.Side Lock 7000. Ideally

the bolt set should touch the front of the lock.

- The front side of the bolt set and the GAT ECO.Side Lock 7000 must be

aligned parallel to each other.

Installation procedure

Note:

Before installing all locks in a new locker system, a test installation

of at least one lock and a final function check must be performed.

Only once the functional testing is successfully completed may the

remaining locks be installed in the same way.

1. Drill 3 holes (3) for the GAT ECO.Side Lock 7000 into the locker wall.

2. Insert the batteries into the GAT ECO.Side Lock 7000 (see page 7).

3. Mount the GAT ECO.Side Lock 7000 with 3 screws (3) on the inside

locker wall.

Attention:

Use the correct screws according to the type of locker

material, max. Ø 4 mm (0.16´´). The maximum allowed

tightening torque of the screws is 2 Nm (1.47 lb-ft).

4. Cut-out a section, 62.6 mm x 68 mm (2.46´´ x 2.68´´), in the inner wall

of the locker door for the GAT NET.Lock Bolt Set 7200.

5. Drill 4 holes (6) in the inner wall of the locker door for mounting the

GAT NET.Lock Bolt Set 7200.

6. Cut-out a section, 67.6 mm x 93.6 mm (2.66´´ x 3.68´´), in the outer

wall of the locker door for the label carrier.

7. Mount the bolt set onto the inside wall of the locker door using 4

screws.

Attention:

Use pan-head metal screws, Ø 3.5 mm (0.14´´), screw

length depends on locker door thickness. The maximum

tightening torque of the screws is 2 Nm (1.47 lb-ft).

8. Push the label carrier onto the outside wall of the locker door. The

label carrier will hold in place with the lashes on the label carrier. To

protect against manipulation, a screw can be used to fix the bolt set to

the label carrier.

Attention:

Use a countersunk screw, Ø 2.9 mm (0.11´´). Screw length

depends on locker door thickness, e.g., a 15 mm (0.59´´)

thick door requires a 19 mm (0.75´´) long screw.