Description

10

Overload protection through an acoustic and

optical warning signal as well as through vibration

Automatic indication of the next calibration date

according to time and/or number of cycles

Fully automatic calibration and adjustment with

the following STAHLWILLE calibration and

adjustment facilities:

perfectControl

®

7794-2 (torque)

perfectControl

®

7794-3 (torque and angle)

Various units (N m, ft.lb, in.lb) may be set

Extension length data can be easily input for

special plug-in tools

After relieving the torque and angle wrench, it is

immediately functional again

Tightening to the right and left is possible.

The torque and angle are shown simultaneously

on the display

Measurement is carried out irrespective of the

force application point.

Safe handling thanks to an ergonomically shaped

handle. The correct gripping position can be seen

and felt

The torque wrench is available in various sizes (see

page 15).

Identification

The torque wrench is identified with a serial number

(S/N) which is printed on the tubular steel housing.

The serial number may also be shown on the

display using the "Version Info" menu item (see

page 34).

A separate ID number (ID No.) can be set using the

TWdrive software. For further information on this,

refer to the TWdrive software online help.

Accuracy

The torque and angle wrench corresponds to

DIN EN ISO 6789 and is based on

VDI/VDE 2648 Part 2. Each torque and angle

wrench is supplied with a factory calibration

certificate.

Symbols and markings

The following symbols and markings can be found

on the torque and angle wrench:

CE symbol

The CE symbol confirms full

adherence to the "Basic (safety)

requirements" defined in EU

directives.

Disposal

Do not dispose of the torque and

angle wrench in household

refuse. Dispose of the torque

and angle wrench through a

certified specialist disposal

company.

USB interface

This symbol identifies the

presence of a USB interface.

Description

11

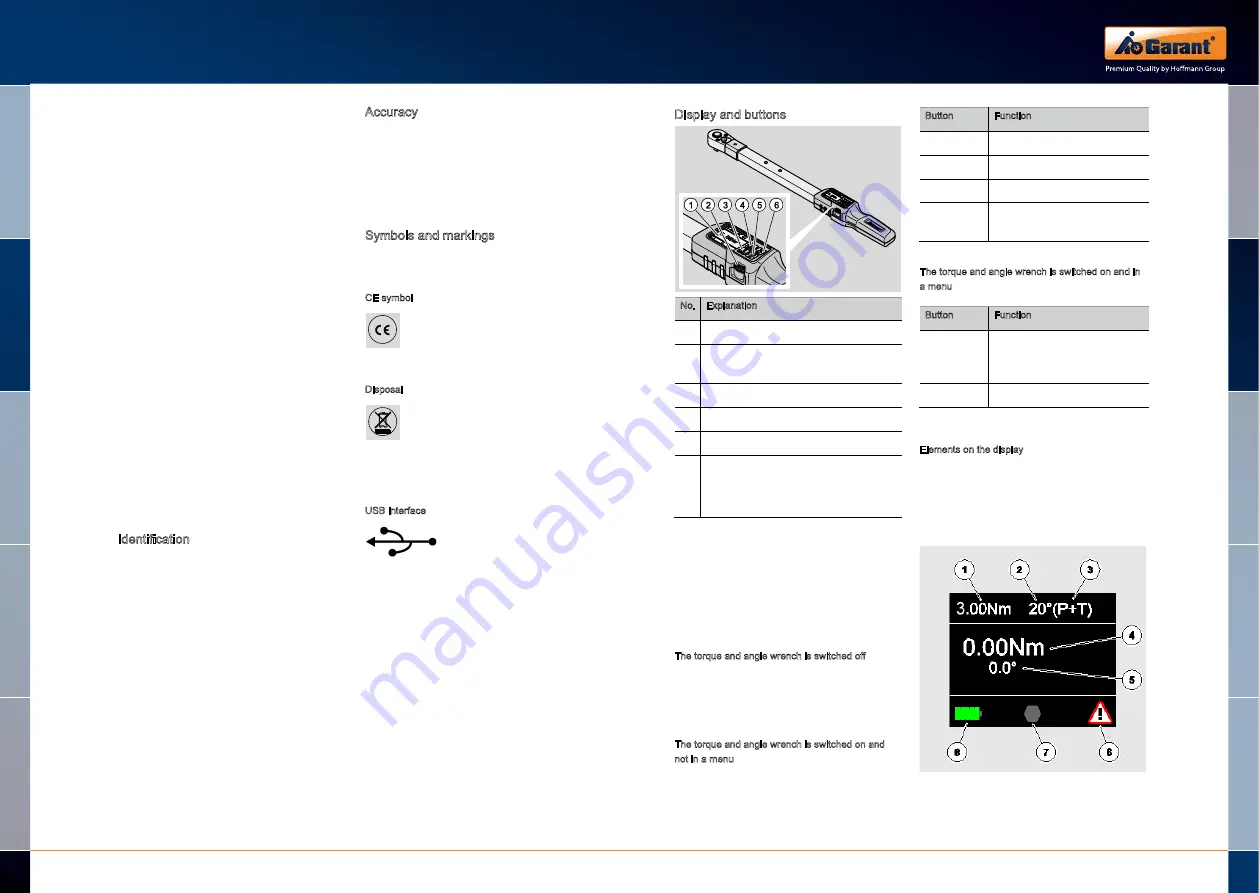

Display and buttons

No. Explanation

1

Display

2

Thumb wheel (select menu item, increase

or reduce values)

3

MENU (call up menu)

4

TARE (taring)

5

OK button (confirmation)

6

ESC (back one menu level)

Switch off (keep the button pressed until the

device switches off)

The four buttons on the torque and angle wrench

can be used to select functions and undertake

settings.

Depending on the operating status of the torque

and angle wrench, the buttons perform different

tasks.

The following tables provide an overview:

The torque and angle wrench is switched off

Any button,

thumb wheel

Switch on

The torque and angle wrench is switched on and

not in a menu

Button

Function

MENU

Call up main menu

ESC

Switch off

TARE

Manual taring

OK

Call up configuration menu or call

up the last torque-angle value

The torque and angle wrench is switched on and in

a menu

Button

Function

ESC

Cancel process,

back step by step in the menu,

switch off

OK

Confirm

Elements on the display

During the tightening procedure, the current torque

or the angle is shown on the display. The displays

are dependent on the set measuring mode.

Information on the current settings is additionally

displayed.

DE

FR

IT

ES

www.hoffmann-group.com

11

10

DE

EN

FR

IT

ES

DE

EN

FR

IT

ES