9

ASSEMBLY INSTRUCTIONS

Hardware Used

GG

KK

10

11

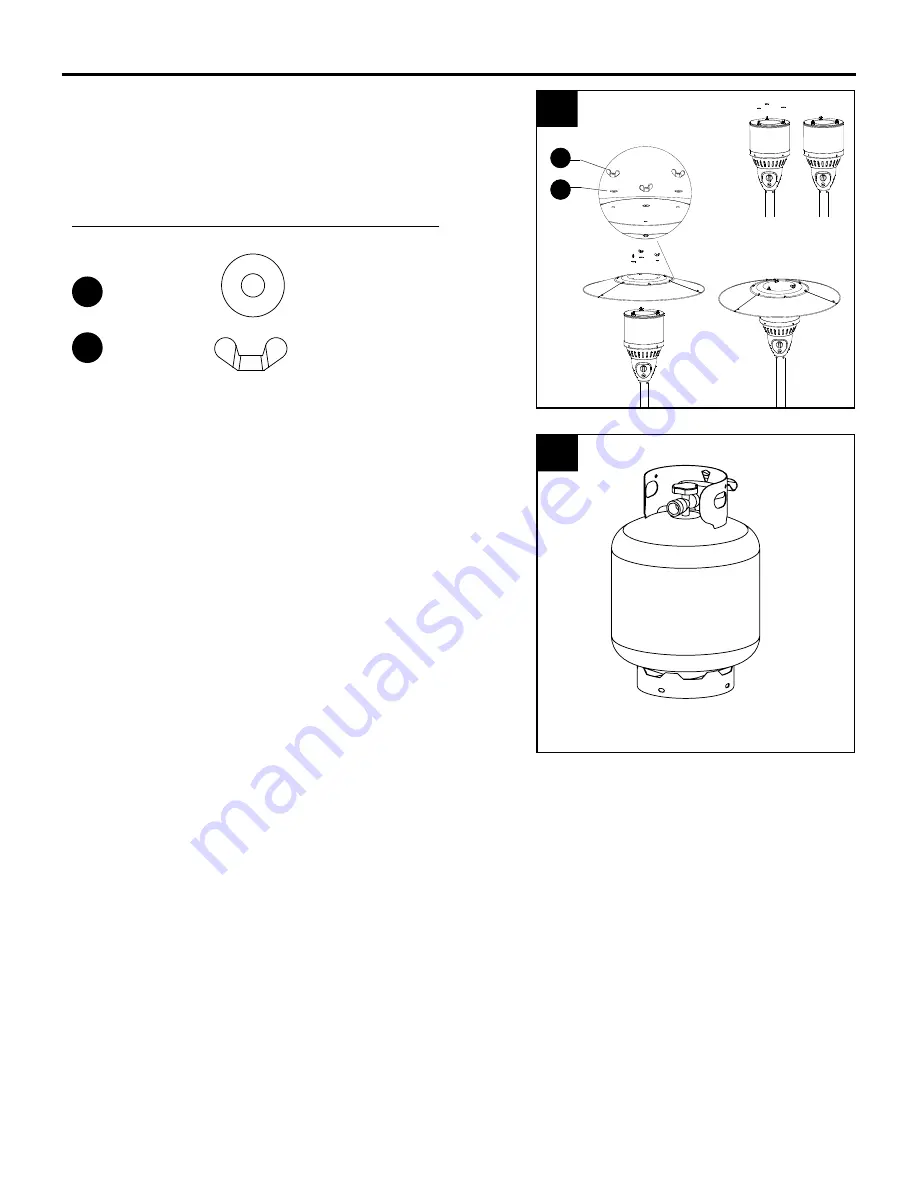

10. Support heater. Slide three washers washer

Φ

8 (GG)

over threaded end of spacer. Locate reflector assembly

on 3 spacers. Install three washers

Φ

8 on spacers and

securely tighten wing nuts (KK) but do not overtighten.

11. Connect hose and regulator to cylinder.

The propane gas and cylinder are sold separately.

Use a standard 20 lb. propane cylinder only.

Use this heater only with a propane vapor withdrawal

supply system. See chapter 5 of the standard for

storage and handling of liquefied petroleum gas,

ANS /NFPA 58. Your local library or fire department

should have this book.

A minimum supply pressure of 0.4 p.s.i. is required for

the purpose of input adjustment for propane gas. Storage

of an appliance indoors is permissible only if the cylinder

is disconnected and removed from the appliance. A

cylinder must be stored outdoors in a well-ventilated

area out of the reach of children. A disconnected cylinder

must have dust caps tightly installed and must not be

stored in a building, garage or any other enclosed area.

The minimum permissible gas supply pressure of 10

W.C. is required for purpose of input adjustment.

The minimum hourly of 17000 Btu is required input

rating for a heater for automatic operation at ratings less

than full input rating.

The pressure regulator and hose assembly supplied

with the appliance must be used.

The installation must conform with local codes, or in the

absence of local codes,with national fuel gas code,

ANS Z223.1/NFPA54, natural gas and propane

Installation Code, CSA B149.1, or propane storage and

handling code, B149.2.

x 6

Washer Φ8

Standard 20 lb. tank

x 3

Wing nut

KK

GG