5

If all cable diameters within the bundle are the same, select your

grip from Table 3.

If individual cable diameter is not known, or the cables within the

bundle are of different diameter, use Table 4.

WARNING

1. Inspect rope for damage prior to use. Do not use a damaged

rope. Using a damaged rope can result in a pull failure and

damage to the cables.

2. Inspect the pulling grip for damage prior to use. Do not use a

damaged pulling grip. Using a damage pulling grip can result

in a pull failure and damage to the cables.

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT

IN SEVERE INJURY OR DEATH

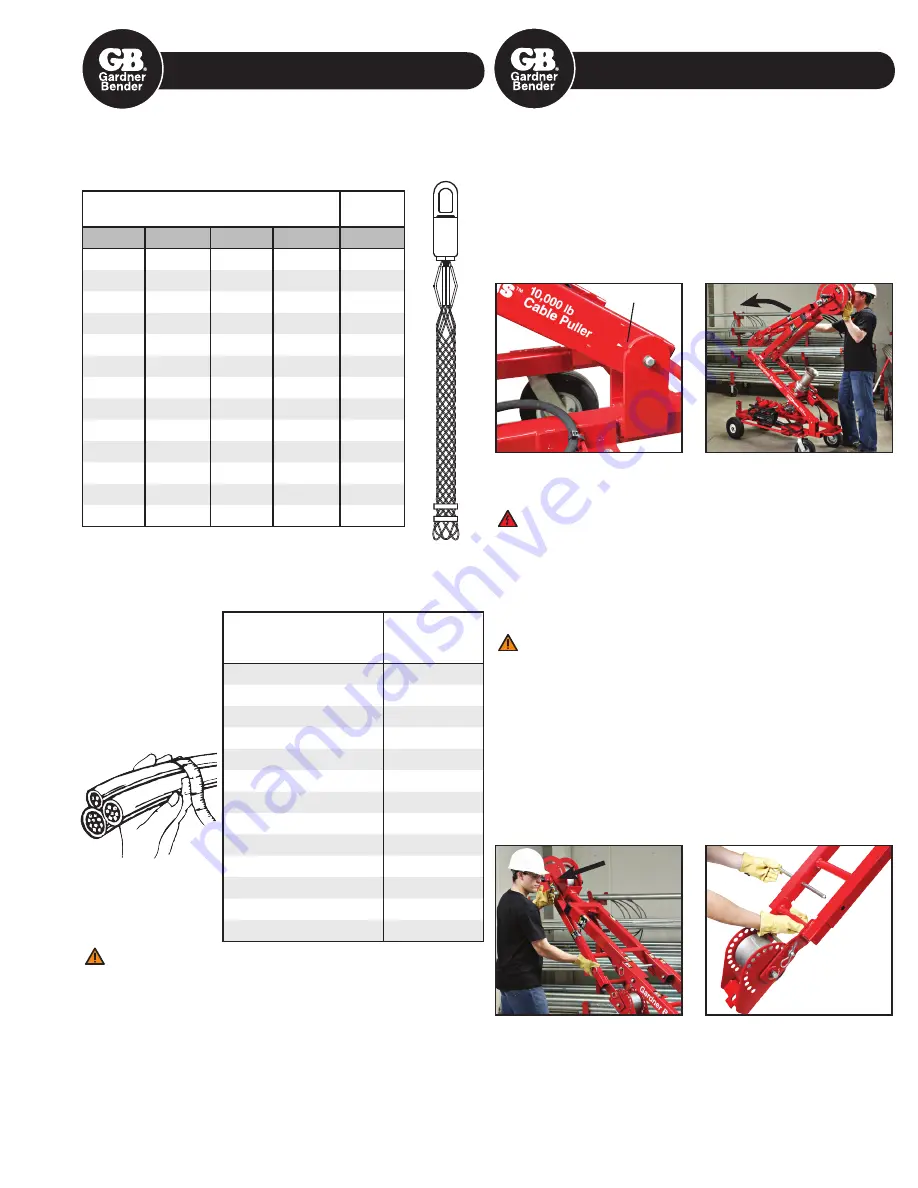

9.1 PULLING UPWARD

1. Position the machine near the conduit box, leaving enough

room to unfold and properly adjust the boom structure.

2. Lock the brakes on the casters.

3. Close the Hydraulic Pump valve by turning clockwise.

Do not

over-torque.

4. Release the pump handle lock and pump the Main Boom up

to a 30 degree angle. The Main Boom pivot bracket is marked

for 30 degrees. (See Picture 1)

5. Remove Boom-A Lock Pin and temporarily store in Pin Clips.

DANGER:

Check for overhead wires prior to unfolding the

boom structure.

FAILURE TO OBSERVE THESE DANGERS WILL RESULT IN

SEVERE INJURY OR DEATH

6. With one hand on the Steering Handle and one hand on

Boom-B, lift and rotate Boom-A and Boom-B together until it

stops inline with the Main Boom. (See Picture 2)

WARNING:

If you do not place your hands as instructed, then

you may crush your hand or fingers. If you do not observe the

machine warning labels, you may crush your hand or fingers.

FAILURE TO OBSERVE THESE WARNINGS COULD

RESULT IN SEVERE INJURY OR DEATH

7.

Re-insert Boom-A Lock Pin and retaining clip.

!! This is extremely important !!

8. While holding on to Boom-B securely, release the Boom-B

Lock Pin. Adjust angle of Boom-B and re-engage the

Boom-B Lock Pin to secure it.

Confirm the pin is fully

engaged.

(See Picture 3)

9. If necessary, adjust the length of Boom-B with the Boom-B

Extension. Remove Boom-B Extension Lock Pin and slide out

the extension to one of 5 lock holes. (See Picture 4)

10. Select the correct size Conduit Adaptor, which is stored on

the machine cart frame.

Table 3. Pulling Grip Guide With Known Cable Diameter

Number of Cables in Each Grip and Diameter Range

INDIvIDuAL CAbLE DIAmETERs

GRIp

DIAmETER

2

3

4

5

Range

.30 – .38

.25 – .31

.22 – .27

.19 – .24

.50 – .61

.38 – .44

.31 – .36

.27 – .31

.24 – .29

.62 – .74

.44 – .59

.36 – .49

.31 – .42

.29 – .38

.75 – .99

.59 – .75

.49 – .63

.42 – .54

.38 – .48

1.00 – 1.24

.75 – .90

.63 – .76

.54 – .65

.48 – .58

1.25 – 1.49

.90 – 1.07

.76 – .89

.65 – .77

.58 – .67

1.50 – 1.74

1.07 – 1.22 .89 – 1.02

.77 – .88

.67 – .77

1.75 – 1.99

1.22 – 1.53 1.02 – 1.28 .88 – 1.10

.77 – .96

2.00 – 2.49

1.53 – 1.83 1.28 – 1.53 1.10 – 1.32 .96 – 1.16 2.50 – 2.99

1.83 – 2.14 1.53 – 1.79 1.32 – 1.54 1.16 – 1.35 3.00 – 3.49

2.14 – 2.44 1.79 – 2.05 1.54 – 1.76 1.35 – 1.54 3.50 – 3.99

2.44 – 2.75 2.05 – 2.30 1.76 – 1.98 1.54 – 1.74 4.00 – 4.49

2.75 – 3.06 2.30 – 2.56 1.98 – 2.20 1.74 – 1.93 4.50 – 4.99

Table 4. Pulling Grip Guide With Unknown Cable Diameter

CIRCumfERENCE RANGE

(inches)

GRIp

DIAmETER RANGE

(inches)

1.57 – 1.95

.50 – .61

1.95 – 2.36

.62 – .74

2.36 – 3.14

.75 – .99

3.14 – 3.93

1.00 – 1.24

3.93 – 4.71

1.25 – 1.49

4.71 – 5.50

1.50 – 1.74

5.50 – 6.28

1.75 – 1.99

6.28 – 7.85

2.00 – 2.49

7.85 – 9.42

2.50 – 2.99

9.42 – 11.00

3.00 – 3.49

11.00 – 12.57

3.50 – 3.99

12.57 – 14.14

4.00 – 4.49

14.14 – 15.71

4.50 – 4.99

9.0 SETTING UP THE MACHINE

8.0 PULLING PREPARATION

Picture 1

Picture 2

Picture 3

Picture 4

Measuring

Circumference

30 Degrees