13--8--616

Page 1

SECTION 1

GENERAL INFORMATION

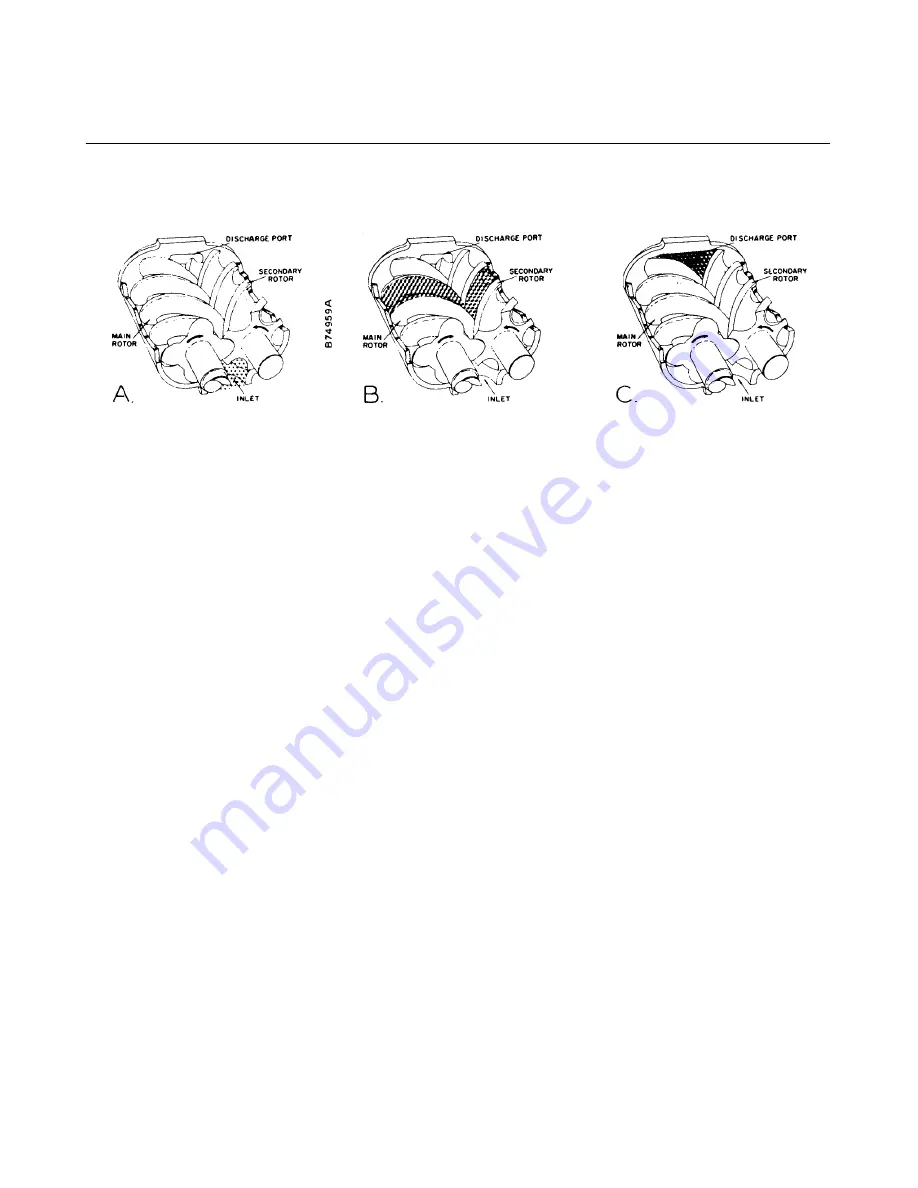

FIGURE 1--1 -- COMPRESSOR CYCLE

COMPRESSOR -- The rotary screw compressor is

a single stage, positive displacement rotary machine

using meshing helical rotors to effect compression.

Both rotors are supported between high capacity roller

bearings located outside the compression chamber.

Single width cylindrical roller bearings are used at the

inlet end of the rotors to carry part of the radial loads.

Ball and roller bearings at the discharge end locate

each rotor axially and carry all thrust loads and the re-

mainder of the radial loads.

COMPRESSION PRINCIPLE (FIGURE 1--1) -- Com-

pression is accomplished by the main and secondary

rotors synchronously meshing in a one--piece cylinder.

The main rotor has four (4) helical lobes 90

_

apart. The

secondary rotor has five (5) matching helical grooves

72

_

apart to allow meshing with main rotor lobes.

The air inlet port is located on top of the compressor cyl-

inder near the drive shaft end. The discharge port is

near the bottom at the opposite end of the compressor

cylinder. FIGURE 1--1 is an inverted view to show inlet

and discharge ports. The compression cycle begins as

the rotors unmesh at the inlet port and air is drawn into

the cavity between the main rotor lobes and the sec-

ondary rotor grooves (A). When the rotors pass the in-

let port cutoff, air is trapped in the interlobe cavity and

flows axially with the meshing rotors (B). As meshing

continues, more of the main rotor lobe enters the sec-

ondary rotor grove, normal volume is reduced and

pressure increases.

Oil is injected into the cylinder to remove the heat of

compression and seal internal clearances. Volume re-

duction and pressure increase continues until the air/oil

mixture trapped in the interlobe cavity by the rotors

passes the discharge port and is released to the oil res-

ervoir (C). Each rotor cavity follows the same “fill--com-

press--discharge” cycle in rapid succession to produce

a discharge air flow that is continuous, smooth and

shock free.

AIR FLOW IN THE COMPRESSOR SYSTEM

(FIGURE 4--1, page 13) -- Air enters the air filter and

passes through the inlet unloader valve and on into the

compression chamber where oil is injected into the air.

After compression, the air/oil mixture passes into the oil

reservoir where most of the entrained oil is removed by

velocity change and impingement and drops back into

the reservoir. The air and remaining oil then passes

through the air/oil separator. The air then passes

through the minimum pressure/check valve, the after-

cooler and the moisture separator and into the plant air

lines.

LUBRICATION, COOLING AND SEALING -- Oil is

forced by air pressure from the oil reservoir through the

oil cooler, thermostatic mixing valve, and oil filter and

discharge into the compressor main oil gallery. A por-

tion of the oil is directed through internal passages to

the bearings and shaft oil seal. The balance of the oil

is injected directly into the compression chamber to re-

move heat of compression, seal internal clearances

and lubricate the rotors.

Summary of Contents for EFD-25 HP

Page 13: ...13 8 616 Page 4 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Page 14: ...13 8 616 Page 5 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Page 30: ...13 8 625 Page 21 FIGURE 4 4 COMPRESSOR RUNNING FULLY LOADED...

Page 32: ...13 8 625 Page 23 FIGURE 4 5 WIRING DIAGRAM 3 305865 Ref Drawing...

Page 33: ...13 8 625 Page 24 FIGURE 4 6 WIRING DIAGRAM 3 305979 A Ref Drawing...

Page 34: ...13 8 625 Page 25 FIGURE 4 7 WIRING DIAGRAM 3 305979 A Ref Drawing...

Page 54: ...13 8 625 Page 45 AIREND GROUP...

Page 60: ...13 8 625 Page 51 AIREND AND INLET FILTER ASSEMBLY...

Page 72: ...13 8 625 Page 63 COOLING GROUP...

Page 74: ...13 8 625 Page 65 CONTROL SYSTEM ASSEMBLY AND MOUNTING...

Page 78: ...13 8 625 Page 69 CONTROL BOX 3 305979 A Ref Drawing...