13--8--625

Page 17

Use the scroll key (

) to get the following information:

DISPLAY

RUNNING MODE

Pressure light on

(1)

Discharge pressure

Temperature light on

(2)

Compressor temperature

Operating hours light

Operating hours

on

(3)

Operating hours

Loaded hours flashing

flashing

(3)

Change Oil light on

(4)

Change oil

Air filter light on

(5)

Replace air filter

Oil separator light on

(6)

Replace air/oil separator

Oil filter light on

(7)

Replace oil filter

No lights on

Compressor running mode

on display

USER MENU -- To enter the User Menu from the basic

display when the compressor is stopped, simul-

taneously push the up arrow and the down arrow keys

and hold for 5 seconds, until all the indicator lights on

the display start flashing, then select code 01.

Use the scroll key (

) to select the desired option for

programming. The numerical values can be changed

with the up arrow or the down arrow keys. The value

flashes on the display to indicate change. When the

flashing stops, the value becomes the new setting.

The following can be programmed through the User

Menu.

Setting the unload pressure:

The pressure indicator light and the upper left seg-

ment of the display illuminate when the unload

pressure is in the programming mode.

The discharge pressure shifts as the unload pres-

sure is changed (the pressure differential remains

constant).

The unload pressure set at the factory is equal to

the compressor’s maximum pressure which can-

not be exceeded.

Setting the discharge pressure:

The pressure indicator light and the lower left seg-

ment of the display illuminate when the discharge

pressure is in the programming mode.

Changing the discharge pressure

will cause the pressure difference to

change.

Compressor automatic timer:

The automatic timer determines how long the

compressor runs unloaded before stopping.

The operating hour light illuminates when the un-

loading time is programmable. This timer is facto-

ry set at 5 minutes.

Automatic start after power failure:

This mode is disabled by setting the value to 0.

Other values define the starting delay of the com-

pressor when power is restored, recommend one

(1) minute or longer.

The operating light flashes when automatic start-

ing is programmable.

Automatic restarting can cause injury

or death. Open, tag and lockout main

disconnect and any other circuits

before servicing the unit.

Condensate removal, open time:

Condensate removal open time is in seconds.

The air filter light illuminates when this can be pro-

grammed.

Too short condensate removal time

at too long an interval may cause wa-

ter to enter the network. Humid and

warm intake air require longer and

more frequent condensate removal.

Too long of a condensate removal

time at too short an interval will

waste compressed air.

Summary of Contents for EFD-25 HP

Page 13: ...13 8 616 Page 4 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Page 14: ...13 8 616 Page 5 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Page 30: ...13 8 625 Page 21 FIGURE 4 4 COMPRESSOR RUNNING FULLY LOADED...

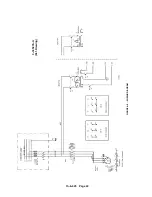

Page 32: ...13 8 625 Page 23 FIGURE 4 5 WIRING DIAGRAM 3 305865 Ref Drawing...

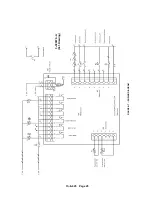

Page 33: ...13 8 625 Page 24 FIGURE 4 6 WIRING DIAGRAM 3 305979 A Ref Drawing...

Page 34: ...13 8 625 Page 25 FIGURE 4 7 WIRING DIAGRAM 3 305979 A Ref Drawing...

Page 54: ...13 8 625 Page 45 AIREND GROUP...

Page 60: ...13 8 625 Page 51 AIREND AND INLET FILTER ASSEMBLY...

Page 72: ...13 8 625 Page 63 COOLING GROUP...

Page 74: ...13 8 625 Page 65 CONTROL SYSTEM ASSEMBLY AND MOUNTING...

Page 78: ...13 8 625 Page 69 CONTROL BOX 3 305979 A Ref Drawing...