13-21-608 Page 14

LOCATION

- The compressor should be installed, whenever possible, in a clean, well-lighted, well-

ventilated area with ample space all around for maintenance. Select a location that provides a cool,

clean, dry source of air. In some cases it may be necessary to install the air filter at some distance from

the compressor to obtain proper air supply.

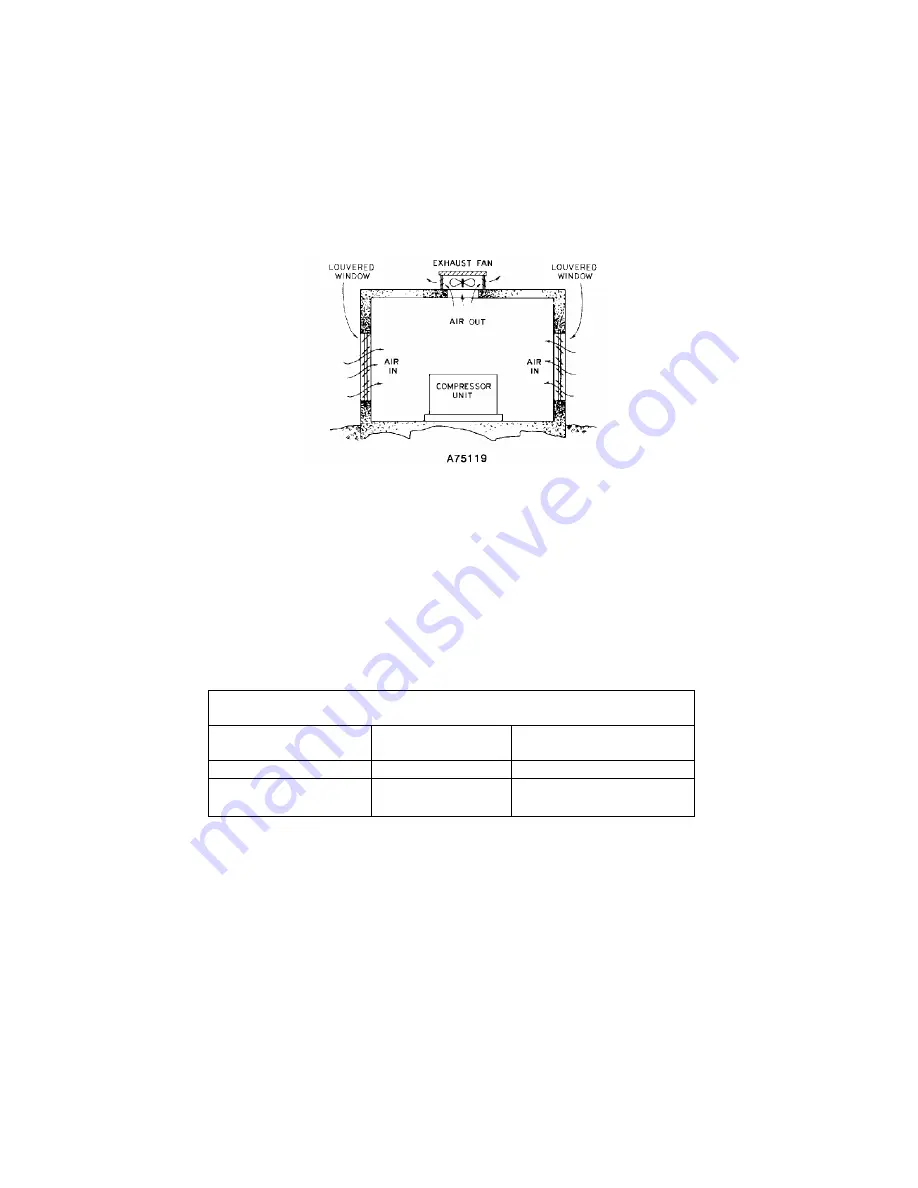

Both the air-cooled and water-cooled units require cooling air as well as air to the compressor inlet.

Proper ventilation MUST be provided; hot air must be exhausted from the compressor operating area. A

typical inlet-outlet air flow arrangement is shown in Figure 2-1.

Figure 2-1 – TYPICAL COMPRESSOR ROOM

Air-Cooled Units

- A combination oil/aftercooler is supplied as standard equipment on all air-cooled

units. The air-cooled unit with the standard enclosure requires sufficient flow, Figure 2-2, for the

compressor oil/aftercooling system and for electric motor cooling. Air is drawn into the unit at the motor

side of the enclosure and is exhausted at the oil cooler side. Do not block the air flow to and from the

unit. Allow three and one-half (3-1/2) feet (1.1 m) to the nearest obstruction on the starter end and control

box end of the unit. Allow three (3) feet (.9 m) to the nearest obstruction above and on other sides of unit.

For continuous efficiency, oil cooler cores must be periodically cleaned with either vacuum or compressed

air. If wet cleaning is required, shield motor and spray on a mild soap solution and flush with clean water.

Minimum Air Flow * For Compression and Cooling

HP (kW)

Air Cooled

Water Cooled

125, 150, 200

(93, 112, 150)

17,000 cfm

481 m

3

/min

4,000 cfm

113 m

3

/min.

* 80

°

F (27

°

C) Inlet Air

Figure 2-2 – AIR FLOW CHART