13-25-637 v02 Page 26

7.1

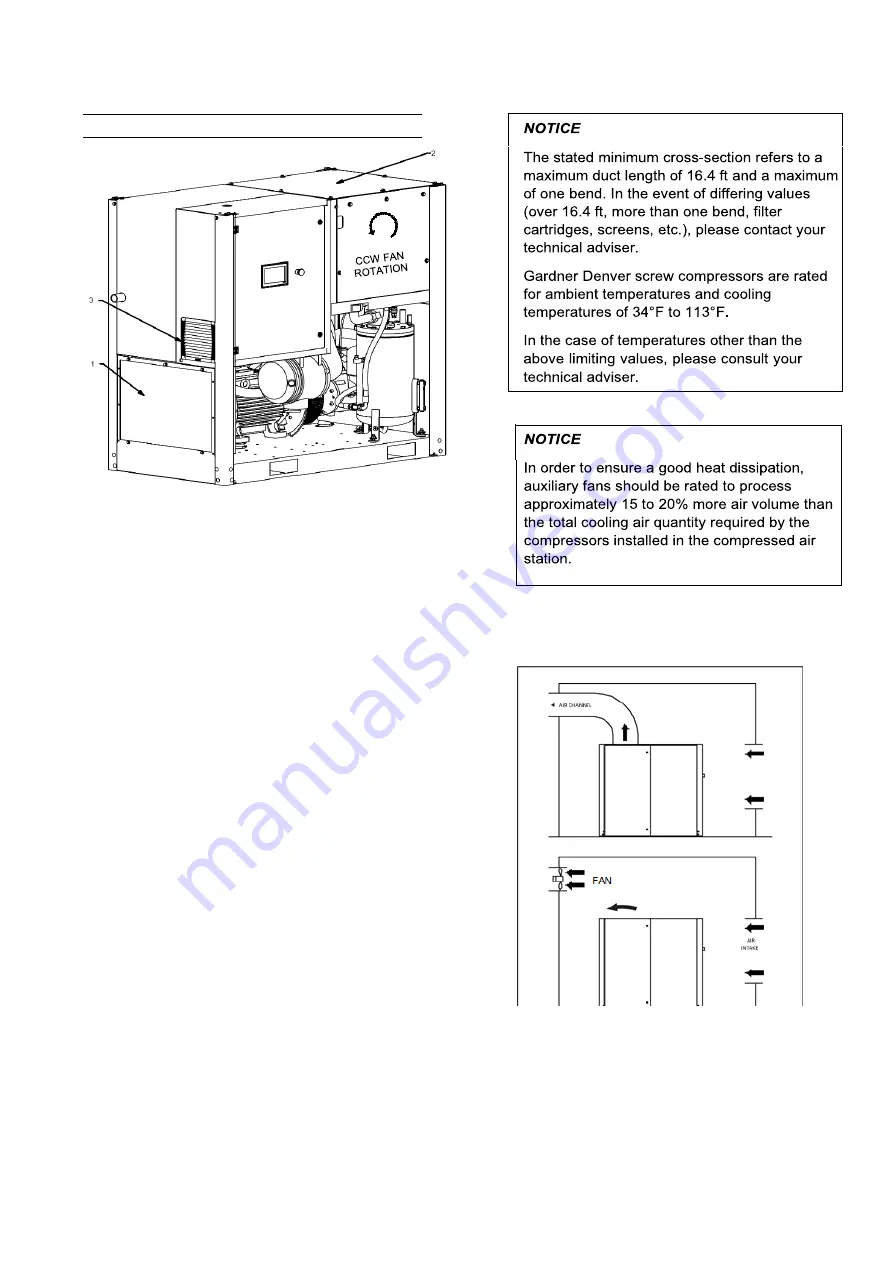

Cooling air volume/minimum cross

Fig. 9

1

Cool air intake

2

Cool air exhaust (Fan rotation counter-clockwise)

3

Control cabinet cool air intake (L30RS-L45RS only)

The cooling air volume required by these screw

compressors is as follows:

L30

2296 cfm

L30RS

2296 cfm

L37

2755 cfm

L37RS

2755 cfm

L45

3073 cfm

L45RS

3073 cfm

If conditions are not favorable, we recommend the

installation of venting ducts. However, the velocity

of the cooling air should not exceed 17ft/sec. We

recommend a minimum duct cross-section of

approx. 6 ft

2

.

The figures below show the recommended

ventilation sections arrangement:

Fig. 10