SB--7--622 Page 2

SECTION 1

EQUIPMENT CHECK

Before uncrating, check the packing slip carefully to be

sure all the parts have been received. All accessories

are listed as separate items on the packing slip, and

small important accessories such as relief valves can

be overlooked or lost. After every item on the packing

slip has been checked off, uncrate carefully. Register

a claim with the carrier for lost or damaged equipment.

Customers are cautioned to provide

adequate protection, warning and

safety equipment necessary to protect

personnel against hazards involved in

installation and operation of this

equipment in the system or facility.

STORAGE

Your Sutorbilt Blower was packaged at the factory with

adequate protection to permit normal storage for up to

six (6) months.

If the unit is to be stored under adverse conditions or

for extended periods of time, the following additional

measures should be taken to prevent damage.

1.

Store the blower in a clean, dry, heated (if

possible) area.

2.

Make certain inlet and discharge air ports are

tightly covered to prevent foreign material from

entering the air box.

3.

All exposed, non--painted surfaces should be

protected against rust and corrosion.

4.

Provide adequate protection to avoid accidental

mechanical damage.

5.

In high humidity or corrosive environments, addi-

tional measures may be required to prevent rust-

ing of the blower internal surfaces.

6.

To prevent rusting of gears, bearings, etc., the oil

reservoirs may be filled with normal operating oil.

Before running the blower, drain the

oil and replace to the proper operat-

ing level with clean, fresh lubricant.

7.

Rotate the blower shaft (10 to 25 turns) monthly

during storage. Inspect the blower shaft (near the

shaft seal area) monthly and spray with rust inhibi-

tor if needed.

8.

For long term storage (over six (6) months),

contact Sutorbilt Customer Service for recom-

mendations.

REMOVING PROTECTIVE MATERIALS

The shaft extension is protected with rust inhibitor

which can be removed with any standard solvent.

Follow the safety directions of the

solvent manufacturer.

Blower inlet and outlet are temporarily capped to keep

out dirt and other contaminants during shipment.

These covers must be removed before start--up.

The internal surfaces of all Sutorbilt units are mist

sprayed with a rust preventative to protect the machine

during shipment. Remove this film upon initial startup,

using any commercial safety solvent. Care should be

exercised to lock out the blower to prevent start--up

Rotating components will cause

severe injury in case of personal

contact. Keep hands away from blow-

er inlet and discharge ports.

Summary of Contents for LEGEND GAF P Series

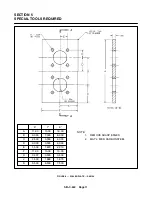

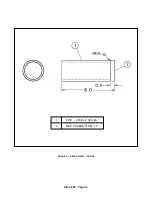

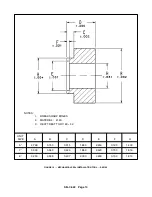

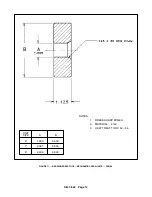

Page 19: ...SB 7 622 Page 12 1 PIPE STEEL 2 SCH 80 2 MED CARBON STEEL 1 2 FIGURE 9 GEAR DRIVER SK2150...

Page 32: ...SB 7 622 Page 25 SECTION 8 PARTS LIST 300GAF810 B Ref Drawing...

Page 34: ...SB 7 622 Page 27 300GAG810 A Ref Drawing...

Page 36: ...SB 7 622 Page 29 300GAH810 A Ref Drawing...

Page 39: ......