18

Caution

Do not crimp the piston cup (4)

when you remove the connecting

rod assembly from the compressor

housing. If the cup is crimped, you

must replace it.

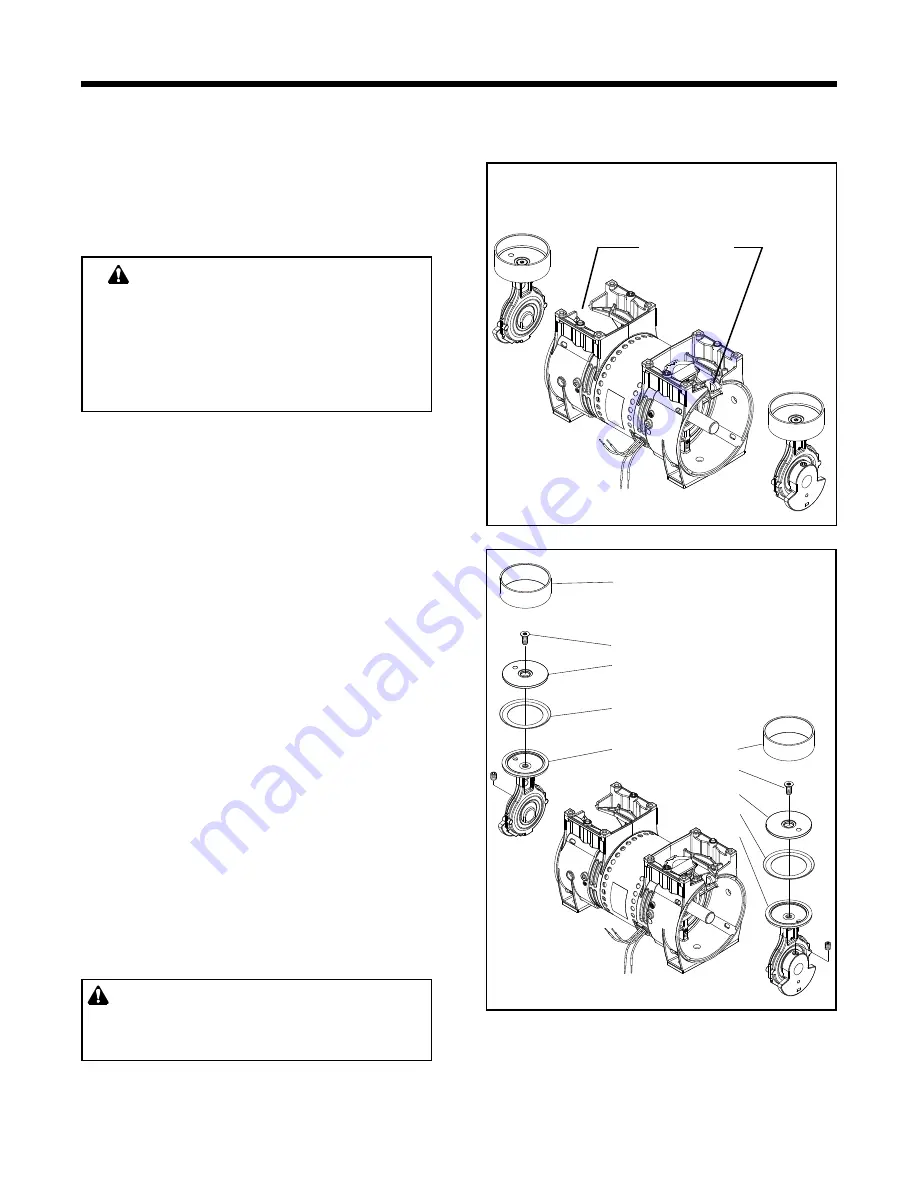

3. Make sure the connecting rod is at "Top

Dead Center". Slide the connecting rod

assembly straight off the shaft through the

opening in the housing.

Opening in

Housing

Rebuilding Connecting Rod Assemblies

If you are rebuilding the connecting rod assembly

using component parts, follow this procedure:

When replacing the piston cup (4), be sure to

replace the sleeve (1) at the same time. Place

the con rod shaft in a fixture before attempting

to remove the retainer screw. Heat will help

to dissolve the loctite bond.

1. Remove the retainer screw (2) from the cup

retainer.

2. Remove the retainer (3) from the connecting

rod.

3. Remove the cup (4) and discard.

4. Place the new piston cup (4) on the connecting

rod.

5. Place a piston cup retainer (3) on the

cup/connecting rod making sure the boss of

the retainer is seated in the pilot of the rod.

6. Insert the retainer screw (2) into the connecting

rod (5) and tighten to 95-105 inch-pounds.

Attention

To replace the connecting rod and

bearing assembly turn to page 19.

Note:

Both Connecting Rods shown for orientation, DO

NOT remove both at once.

1

2

3

4

5

1

2

3

4

5

Summary of Contents for Thomas 2660AT32-492W

Page 2: ...2...

Page 6: ...6 Exploded View and Parts List Exploded View of the Thomas 2660AT32 492W...

Page 23: ...23 NOTES...

Page 24: ...24...