GB

| Operating Instructions

GB-12

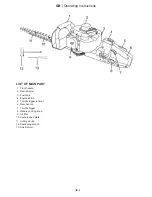

Air filter

1.

Loosen the air filter cover screw and remove the air

filter cover.

2.

Wash the air filter in solvent.

3.

Thoroughly squeeze the filter removing excess oil.

18

15

4.

Reinstall the air filters.

5.

Reinstall the air filter cover, and tighten the air filter

cover screw.

WARNING

The use of petrol or combustible solvents for cleaning can

cause fire or explosion. Therefore only use soap water

or non-combustible solvent. Never operate the machine

without the air filter.

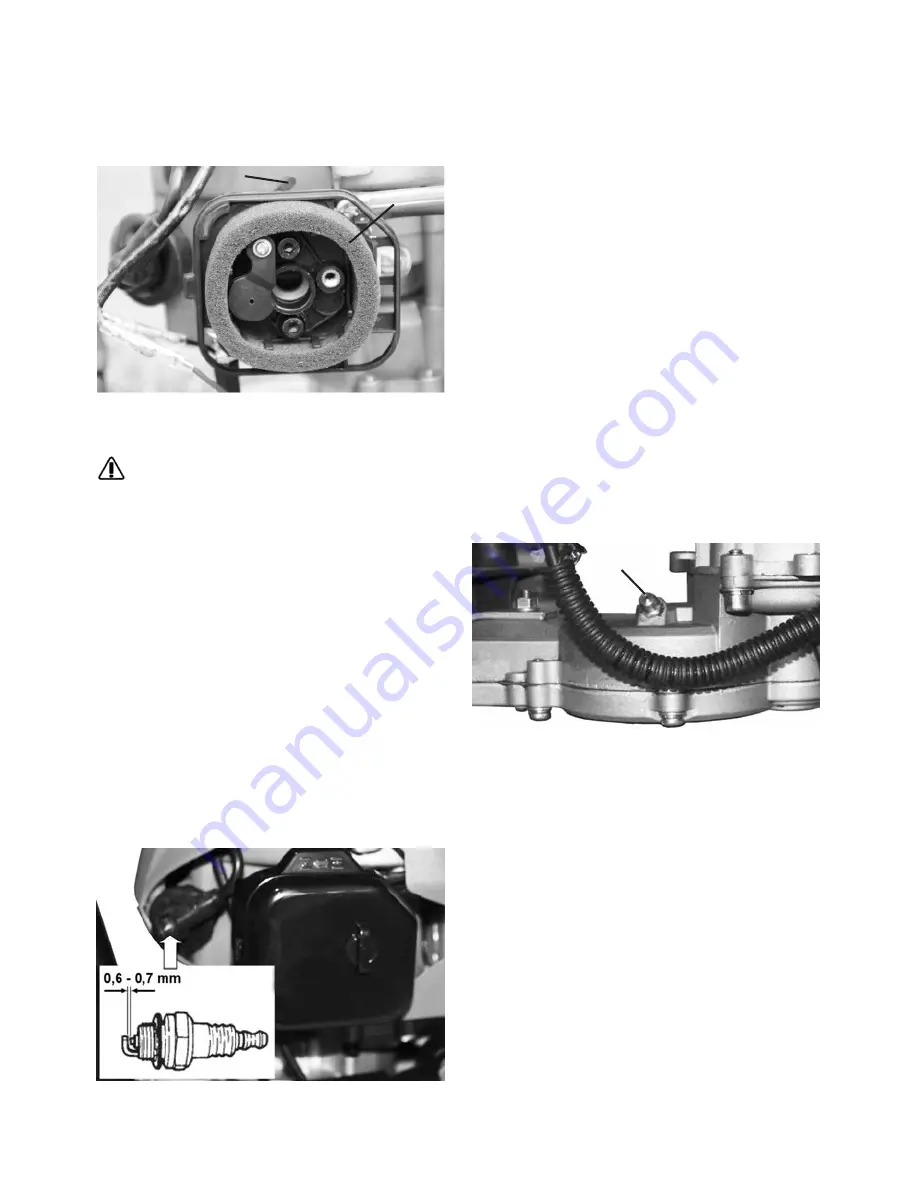

SPARK PLUG

RECOMMENDED SPARK PLUG: SAIL BM6A

To ensure proper engine operation, the spark plug must

be properly gapped and free of deposits.

1. Remove the spark plug cover from the housing.

2. Remove the spark plug cap.

3. Clean any dirt from around the spark plug base.

4. Use the spark plug wrench which provided to remove

the spark plug.

5. Visually inspect the spark plug. Remove carbon depo-

sits using a wire brush.

6. Check for discoloration on the top of the spark plug.

The standard color should be a tan color.

7. Check the spark plug gap. The acceptable gap should

be between 0,6-0,7mm.

8. Install /reinstall the spark plug carefully by hand.

9. Once the spark plug has been seated, tighten it with

a spark plug wrench.

10. Reinstall the spark plug cap on top of the spark plug.

11. Reinstall the spark plug cover.

Cleaning

1. Keep your machine clean, the outside of the machine

can be cleaned using a damp soft cloth with a mild

detergent if required, never use water to clean the

machine as it may cause damage to internal parts.

2. Some maintenance products and solvents may dama-

ge the plastic parts, these include products containing

benzene. Trichloroethylene, chloride and ammonia.

3. Take special care to keep the ventilation inlets /outlets

free from obstruction. Cleaning with a soft brush follo-

wed by a compressed air jet will usually be sufficient

to ensure acceptable internal cleanliness.

4. Wear eye protection when carrying out cleaning.

Gear

There is a grease nipple and a plug for filling lubricant on

the gear housing. Use a grease gun to fill with grease.

This should be done after every 30 working hours. Use

special grease which can withstand high temperature and

high pressure.

17

CAUTION!

The gear housing must not be filled completely with gre

-

ase. The grease expands as the machine heats up during

operation. If the gear housing was completely filled with

grease it could damage the seals and lead to leakage of

grease.

The grease in the bevel gear does not normally need to

be changed except if repairs are carried out.