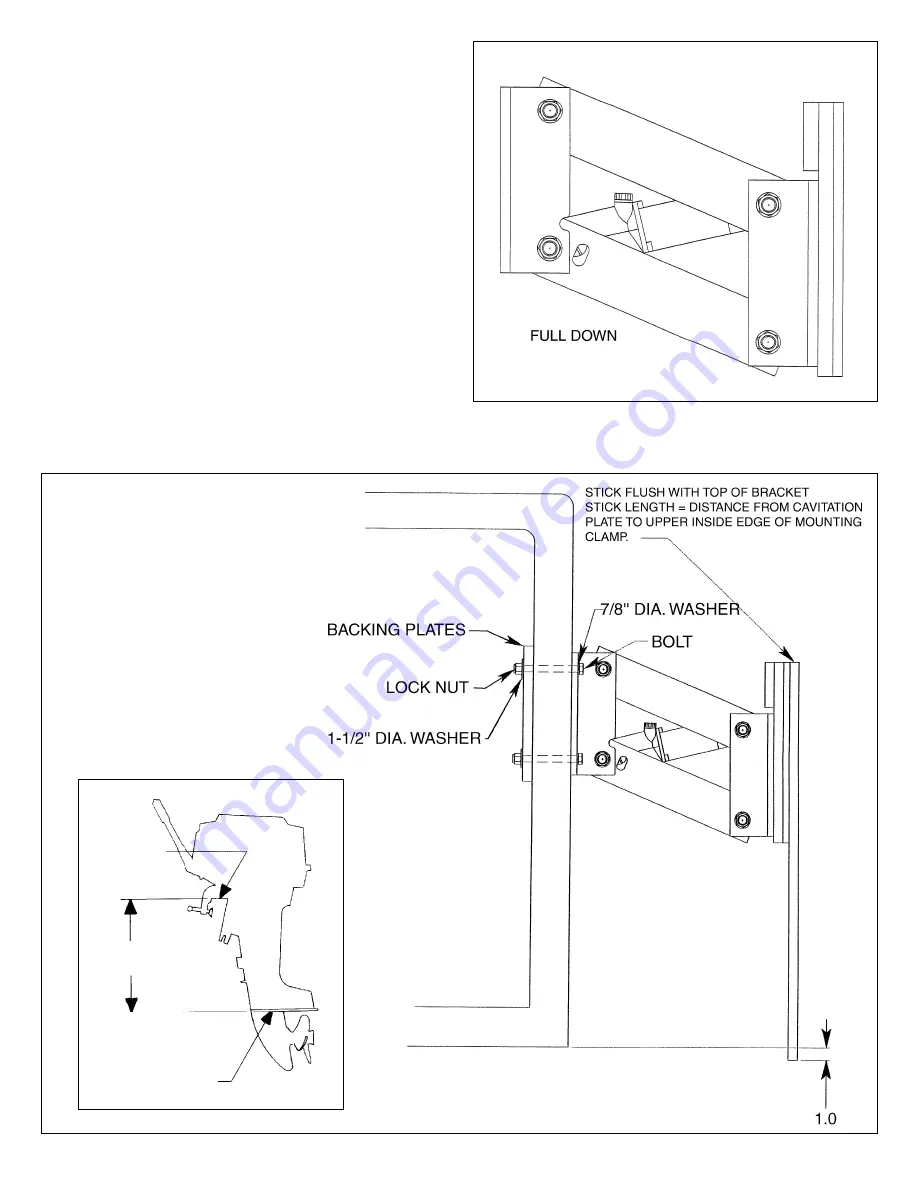

2. Measure the distance on your outboard motor between the

cavitation plate and the upper inside edge of the mounting

clamp. Cut a stick to this length and tape it to the mounting

board with one end flush with the top of the board. (See

Fig. 3)

3. Choose the most appropriate side of your transom for

mounting the Bracket. Position your Bracket so it will not

interfere with the turning operation of your main motor or

rudder. Slide the Bracket up or down so that the bottom of

the stick is approximately 1” or 2” below the bottom of the

boat. Note: The bottom of the stick represents the cavitation

plate on your outboard which must be below the boat’s

bottom for best performance. Make sure the bracket is

parallel to the main power source or straight up and down

left to right. Mark 4 mounting holes. Note: Gain access to

the inside of the transom area where the installation is to

be bolted through. Make sure the area is clear of any fuel

or electrical lines. Because of the combined weight of the

motor and Bracket, it is highly recommended that backing

plates be used to help strengthen the installation. A

minimum size of 3/4” thick, 4-1/2” wide and 10-1/2”

long made from a marine grade plywood, aluminum or

starboard, one for each mounting flange. (See Fig. 3)

FIG. 2

FIG. 3

2

INSIDE OF TOP

OF CLAMP

MEASURE

THIS DISTANCE

CAVITATION PLATE