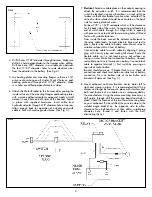

4. Drill 4 holes 17/32” diameter through transom. Make sure

drill bit is held perpendicular to the transom when drilling.

Drill one hole, 3/8” diameter in a suitable area between

the four 17/32” diameter holes to route electrical wires

from the actuator to the battery. (See Fig. 4)

5. Lay backing plates over mounting flanges so there is 1/2”

or more of overhang on all 4 sides. Mark 2 holes on each

backing plate and through drill 17/32” diameter. Make

sure holes are drilled perpendicular to surface.

6. Attach the Motor Bracket to the transom after coating the

inside surfaces of the mounting flanges and backing plates

with a marine adhesive/sealant compound. Apply a small

amount in each hole on both sides of the transom. Secure

in place with supplied hardware. Insert cable from

hydraulic actuator through 3/8” diameter hole in transom.

Allow enough slack for operation of actuator and caulk

cable in hole with marine grade silicone. (See Fig. 3)

FIG. 4

7.

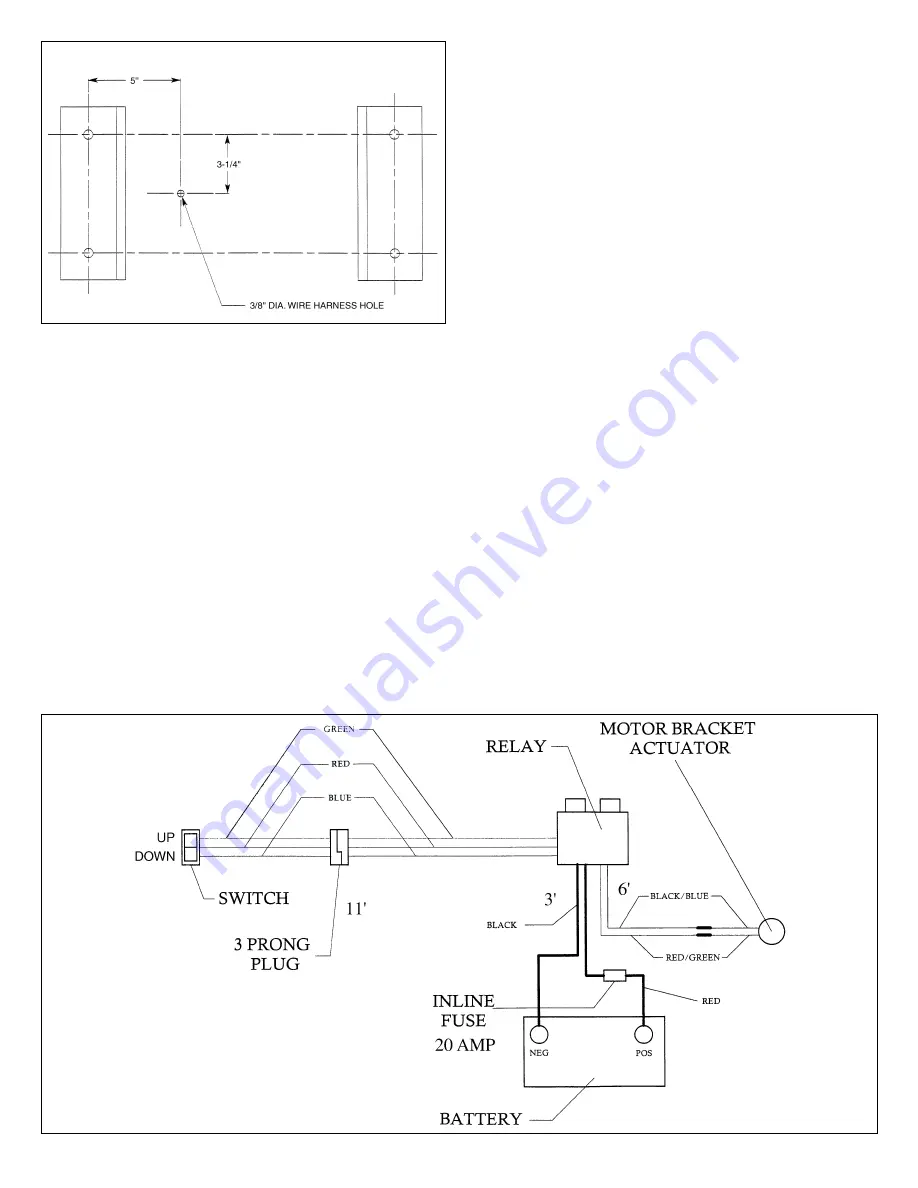

Electrical

Select a suitable place on the cockpit coaming to

attach the activation switch. It is recommended that the

switch be located in an area that allows a visual sight line

to observe the Motor Bracket’s motion when activated. The

vertical surface selected should be accessible on the back

side for routing electrical wires.

Scribe a 7/8” x 1-5/8” rectangle which will be clearance

for the back side of the switch. Cut opening and feed plug

end of switch cable through first. Align switch in opening

with green wire on top. Mark four mounting holes, drill and

fasten with suitable fasteners.

From inside the boat, connect the actuator cable leads to

the relay cable leads. Connect black to blue and red to

green. Route relay cable to battery area. Mount relay to

suitable surface within 3 feet of battery.

Connect relay cable to switch cable by aligning 3 prong

plug with 3 cavity plug and mating full closed. Route the

flexible cable so it is not touching any hot surfaces or

laying in water. Make final connection to battery. Connect

red cable to positive (+) terminal on battery. Connect black

cable to negative terminal (-). Test switch by pressing on

top side of rocker button.

Bracket should come up. If bracket fails to rise, check all

connections and check reset button on inline fuse at battery

connection. Press on bottom side of rocker button and

bracket will descend. (See Fig. 5.)

8. Mount outboard on Motor Bracket. Center motor left to

right and clamp in place. It is recommended that 25 hp

motors and larger be fastened in place with stainless steel

bolts and locknuts of a suitable size as recommended by

the manufacturer. Using the motor mounting bracket as a

drill guide, through drill the mounting board and bolt in

place. Check the location of the two lowest mounting holes

on your outboard. If, when drilled, they are too close to the

welded angle bracket on the opposite side to allow

clearance for a bolt head or nut, then drill a suitable tap

diameter hole, thread it and fasten with the bolt,

eliminating the nut.

FIG. 5

3