Part # 1382670 (12/07)

Page 10

Possible Settings

PIZZA PRODUCT

TIME

TEMP F

TEMP C

UPPER

LOWER

Fresh Dough Cheese Pizza

6:00-7:00

450-575

234-250

Fully Closed

Fully Open

Fresh Dough with Toppings

7:30-8:30

450-475

234-250

1/2 Open

Fully Open

Pre-Baked Dough Cheese Pizza

5:00-6:00

450-475

234-250

1/2 Open

Fully Open

Pre-Baked Dough with Toppings

5:30-6:30

450-475

234-250

1/2 Open

Fully Closed

Pre-Cooked Black Porcelain Pan

10:00-12:00

475-500

250-260

Fully Closed

Fully Open

Deep Pan Pizza

8:30-9:30

475-500

250-260

Fully Closed

Fully Open

Pre-Baked Party Pizza

16:00-20:00

475-500

250-260

Fully Closed

Fully Open

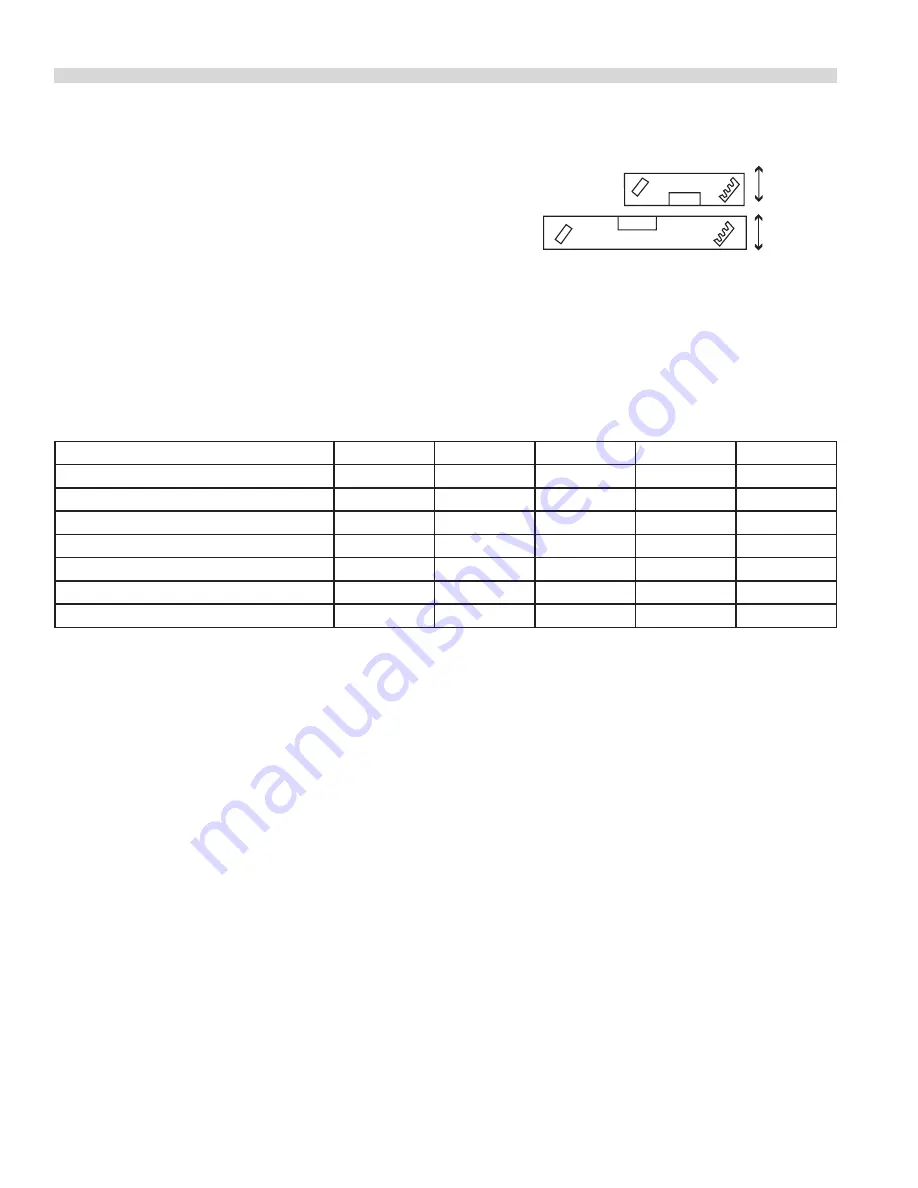

Air Shutter Adjustments

To adjust the dampers, loosen wing nut holding damper

position, with deck and damper tool provided, insert the

damper end of the tool into the receptacle on the damper,

and raise the damper to disengage the damper from the

notched position, slide the damper at a 45 degree angle to

engage the next position, retighten wing nut .

OPERATION Continued

Decrese Air

Decrese Air

Increase Air

Increase Air

Upper Damper

Lower Damper

To increase Top air, adjust upper damper “down” . Position in

notch, and tighten thumb screw .

To increase Bottom Air, adjust lower damper “up” . Position

damper in notch, and tighten thumb screw .

Summary of Contents for Air-Deck G56PT

Page 19: ...Part 1382670 12 07 Page 19...

Page 20: ......