400W Series

190-01226-14 Rev. 3

Instructions for Continued Airworthiness Bell 407

Page 13 of 26

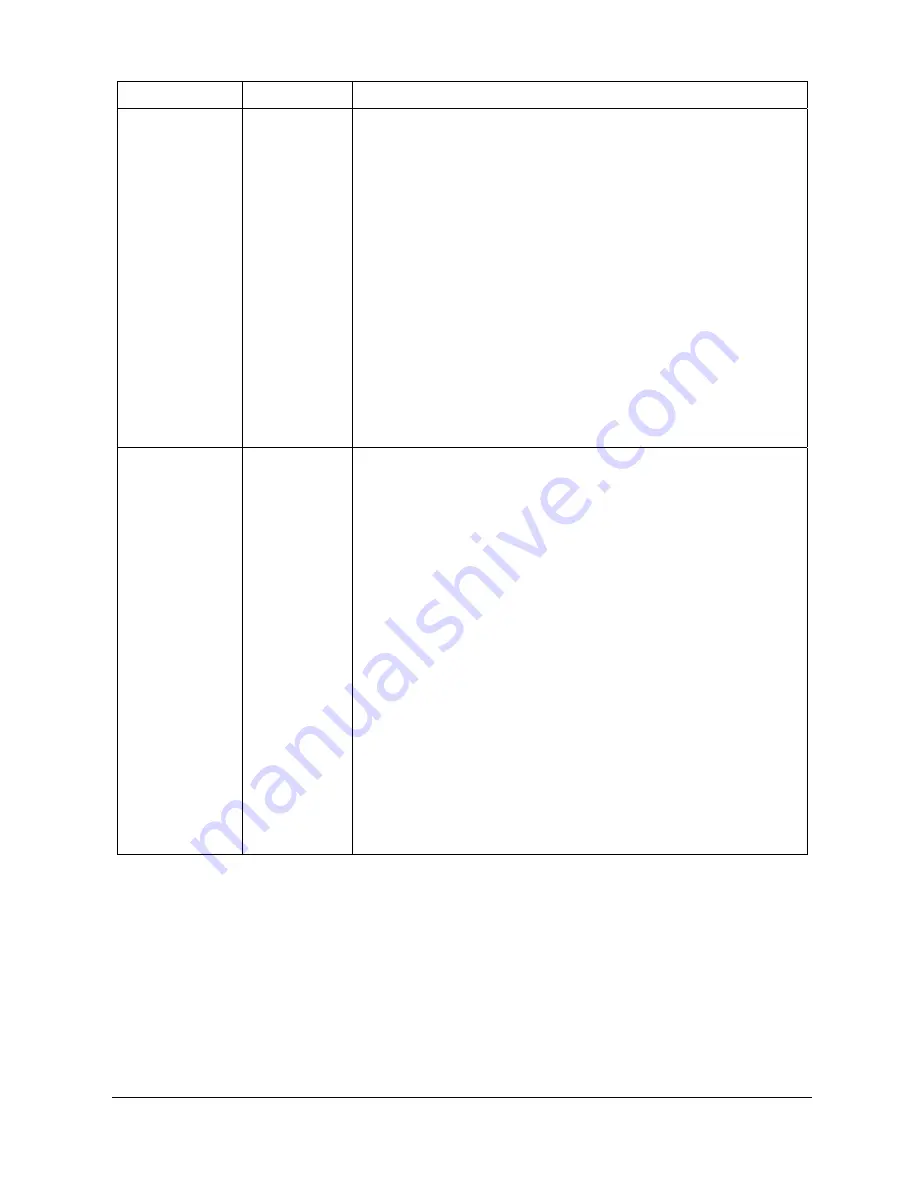

Item Interval

Description/Procedure

GPS Antennas

(Only if antenna

is installed by

this STC)

Every 2000

flight hours or

ten (10)

years,

whichever is

first

Perform an electrical bonding test on antennas installed by this

STC:

1. Disconnect coaxial cable(s) from the antenna connector(s).

2. Measure the resistance between the antenna connector and

a nearby exposed portion of the antenna foil ground plane.

3. Verify the resistance is equal to or less than 10 milliohms.

4. Reconnect the coaxial cable(s) to the antenna connector(s)

and ensure it is secured.

In the event of bonding test failure, remove antenna, and clean

and prepare the hardware mating surfaces as follows:

Clean countersunk areas of the antenna. Clean countersunk

areas using an approved solvent per Bell Specification BHT-

ELEC-SPM, CHP 8.

Reinstall using unit replacement procedures contained in the

installation drawing listed in paragraph 2.1 of this document. Any

reworked antenna installation shall have a resistance of less than

or equal to 2.5 milliohms.

HTAWS

Annunciators (if

installed)

Every 2000

flight hours or

ten (10)

years,

whichever is

first

Perform an electrical bonding test:

1. Measure the resistance between the metallic body of each

Vivisun annunciator and the console assembly and verify

that the resistance is less than or equal to 20 milliohms.

In the event of bonding test failure:

1. Inspect the grounding strap which is installed between the

annunciator panel and the instrument panel. Ensure that the

fastener hardware is secure and that the strap is not

damaged. If damaged, replace the bonding strap. For

annunciator installation with annunciator mounted in

instrument panel verify mating surfaces are clean and free

of corrosion.

2. If problem persists, remove the bonding strap and clean the

mating surfaces of the bonding strap and

annunciator/instrument panel per Bell specification BHT-

ELEC-SPM CHP8. For installations with the annunciator

mounted in instrument panel clean the mating surfaces.

3. Reinstall the bonding strap (or annunciator when mounted

in instrument panel) and verify that the resistance between

the annunciators and the console assembly after prepping

bonding surface is less than 10 milliohms.

2.5.1 Cleaning the Front Panel

The front bezel, keypad, and display can be cleaned with a soft cotton cloth dampened with clean water.

DO NOT use any chemical-cleaning agents. Care should be taken to avoid scratching the surface of the

display.

2.5.2 Display Backlight

The display backlight lamp is rated by the manufacturer as having a usable life of 20,000 hours. This life

may be more or less than the rated time depending on the operating conditions of the 400W Series unit.

Over time, the backlight lamp may dim and the display may not perform as well in direct sunlight

Summary of Contents for 400W Series

Page 26: ......