Garmin G5 Install Manual & Pilot's Guide

190-02072-00 Rev. E

13

Unit Installation

Installation Manual

Pilot's Guide

Appendix

Index

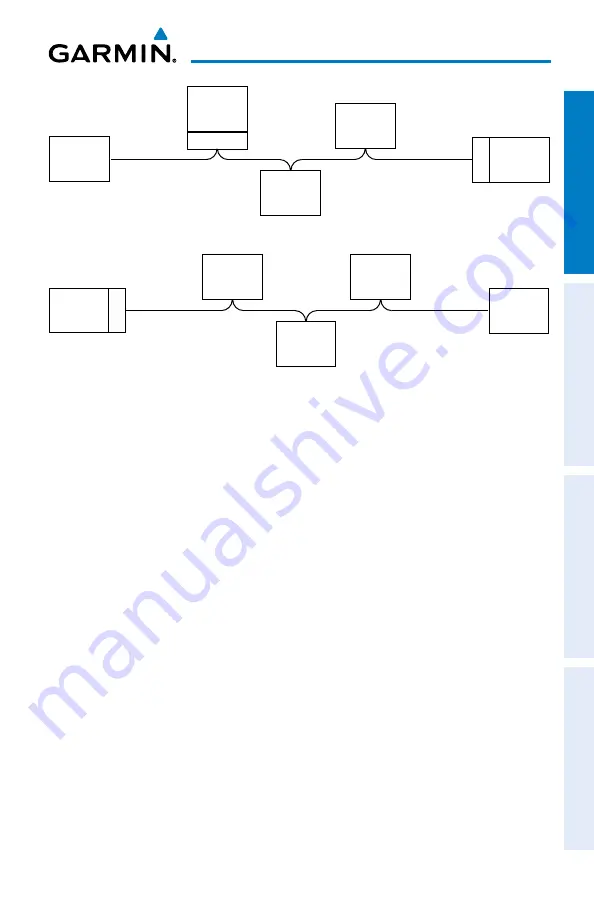

INCORRECT - ONE OF THE TERMINATIONS IS NOT AT THE END OF THE BACKBONE

LRU

LRU

LRU

LRU

LRU

TERM

TERM

INCORRECT - ONLY ONE END OF THE BACKBONE IS TERMINATED

LRU

LRU

LRU

LRU

LRU

TERM

Figure 1-10 Incorrect CAN Bus Termination Examples

1.2.2.2.4 Can B

uS

Lru r

emovaL

G

uideLineS

The following should be considered when removing an LRU from the ends of the

CAN bus.

• GAD 29, GMU 11, GPS 20A, G5, or other devices that use the 9-pin CAN

termination adapter: The CAN bus will remain terminated as long as the CAN

termination adapter is left connected to the cable assembly.

• GSA 28: A removal adapter (part number 011-03158-00) is provided with

each GSA 28 connector kit. This adapter can be used when a GSA 28 is

removed from the aircraft. The removal adapter keeps the node on the CAN

bus in the same state as when the servo was installed (either terminated or

un-terminated). The removal adapter also allows trim signals to pass through

when no servo is installed.

Summary of Contents for Approach G5 - GPS-Enabled Golf Handheld

Page 1: ...G5 Install Manual Pilot s Guide ...

Page 2: ...Blank Page ...

Page 3: ...INSTALLATION MANUAL PILOT S GUIDE APPENDIX INDEX ...

Page 4: ...Blank Page ...

Page 16: ...Garmin G5 Install Manual Pilot s Guide 190 02072 00 Rev E iv Table of Contents Blank Page ...

Page 237: ...Garmin G5 Install Manual Pilot s Guide 190 02072 00 Rev E Blank Page ...