1

Place the cable-entry cover over the hole and the cable,

with the opening pointing downward, and mark the location of

the two pilot holes.

2

Remove the cable-entry cover, and, using a 3.2 mm (

1

/

8

in.)

bit, drill the pilot holes approximately 10 mm (

3

/

8

in.) deep.

3

Fill the pass-through hole with marine sealant so it covers the

cable completely and there is excess sealant around the hole

and the cable.

4

Place the cable-entry cover over the hole and the cable, with

the opening pointing downward.

5

Apply marine sealant to the included 12 mm M4 screws, and

attach the cable-entry cover to the transom.

6

Wipe away all excess marine sealant.

Testing the Installation

NOTICE

You should check your boat for leaks before you leave it in the

water for an extended period of time.

Because water is necessary to carry the sonar signal, the

transducer must be in the water to work properly. You cannot

get a depth or distance reading when out of the water. When

you place your boat in the water, check for leaks around any

screw holes that were added below the water line.

Testing the Transom-Mount Transducer Installation

NOTICE

When adjusting the depth of the transducer, make the

adjustments in small increments. Placing the transducer too

deep can adversely affect the performance of the boat and put

the transducer at risk of striking underwater objects.

Test the transom-mount transducer installation in open water

free of obstacles. Pay attention to your surroundings as you test

the transducer.

1

With the boat in the water, turn on the chartplotter.

2

Drive the boat at a slow speed. If the chartplotter appears to

be working properly, gradually increase speed while

observing the chartplotter.

3

If the sonar signal is suddenly lost or the bottom return is

severely degraded, note the speed at which this occurs.

4

Return the boat to the speed at which the signal was lost,

and make moderate turns in both directions while observing

the chartplotter.

5

If the signal strength improves while turning, adjust the

transducer so that it extends another

1

/

8

in. (3 mm) below the

transom of the boat.

6

Repeat steps 2–4 until the degradation is eliminated.

7

If the signal does not improve, move the transducer to a

different location on the transom, and repeat the test.

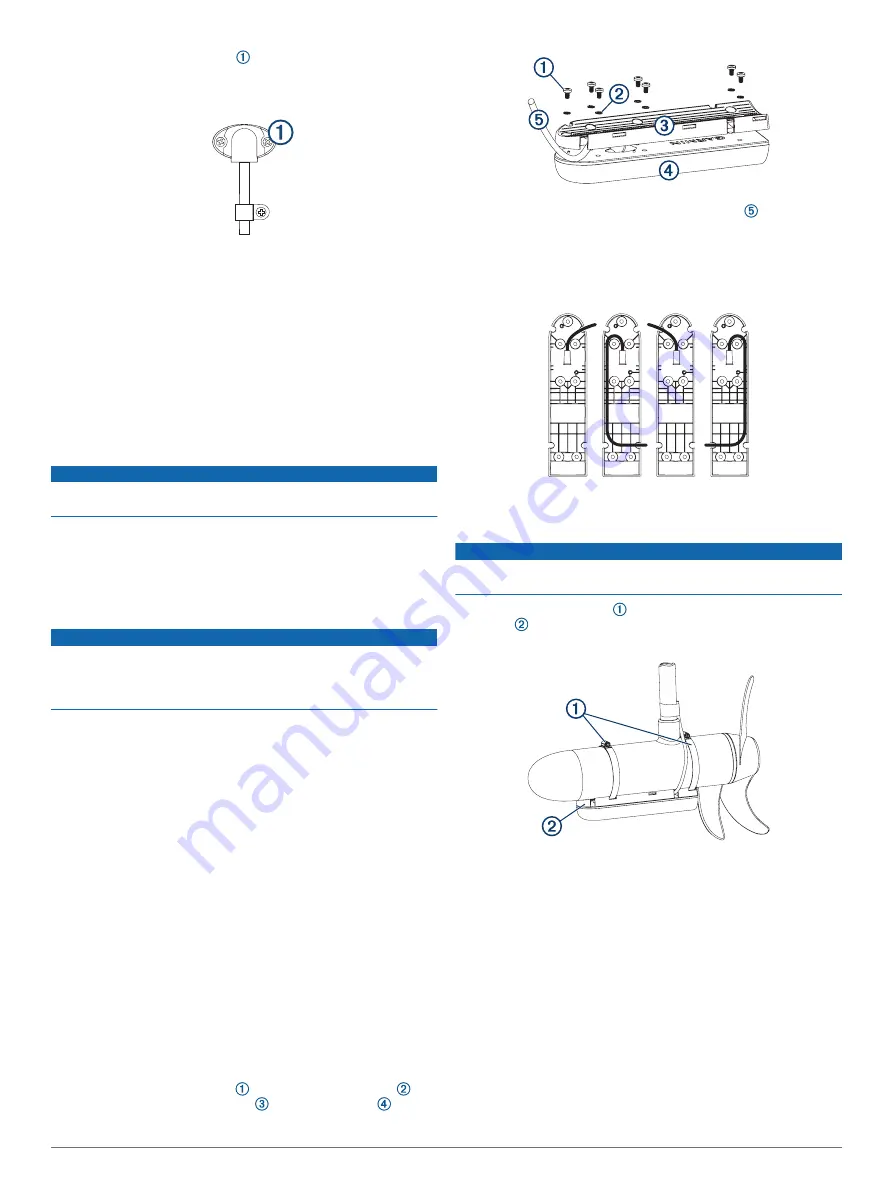

Installing the Transducer on a Trolling Motor

Assembling the Trolling Motor Mount

1

Using the 8 mm M4 screws and 4 mm star washers ,

attach the trolling motor mount to the transducer .

2

Before tightening the screws, route the cable inside the

mount to a cable exit.

The trolling motor mount is designed with multiple cable exits.

You should use a cable exit that allows the cable to be on the

top side of the trolling motor housing when the motor is

stowed. See the image below for recommended cable routes.

You must avoid pinching the cable or bending it too tightly.

Attaching the Transducer to the Trolling Motor

NOTICE

Do not cut the transducer cable. Cutting the transducer cable

will void your warranty.

1

Insert the hose clamps through the slots on the transducer

mount , until equal lengths extend on both sides of the

mount.

2

Place the transducer mount against the body of the trolling

motor with the narrow end of the transducer pointed away

from the propeller.

3

Secure the hose clamps around the body of the trolling

motor, and tighten the hose clamps.

4

Position the transducer so it is parallel to the bottom when in

use.

5

Use waterproof tape (not included) to secure the transducer

cable to the trolling motor shaft.

6

Route the transducer cable to the installation location of the

chartplotter while taking these precautions.

• You should avoid routing the cable close to electrical wires

or other sources of electrical interference.

• You must avoid routing the cable where it is pinched when

the trolling motor is deployed or stowed.

3