190-01115-01

G3X/G3X Touch Installation Manual - GSA 28 Installation

Rev. AC

Page 17-2

GSA 28 autopilot servos can be used to control the trim system in an aircraft. When the autopilot is

disengaged, the servos can adjust the trim speed based on the current aircraft airspeed. This allows the trim

to run slower at high airspeeds and faster at low airspeeds. When the autopilot is engaged in the air, the

servos can adjust the trim control to minimize the force on the primary controls. This helps ensure the

aircraft will be properly trimmed when the autopilot is later disengaged.

During the flight test phase, the trim system is configured and set up after the primary autopilot

performance has been properly configured. This is done so the pilot can focus on properly adjusting the

performance of the primary autopilot system without having the auto-trim functionality interfere.

NOTE

Ensure basic autopilot functionality is properly adjusted before enabling trim control for

any servo.

17.1.1 Status LED

The GSA 28 has an LED on its outer case that indicates its current status. See

for details.

17.2 Equipment Available

17.3 General Specifications

17.3.1 Power Specifications

The trim outputs are capable of sourcing a maximum of 1 Amp of current to drive a brushed DC motor.

The trim outputs drive a maximum output voltage of 12 Vdc.

CAUTION

The GSA 28 is compatible with 14 Vdc trim systems only. Do not connect the GSA 28 to a

28 Vdc trim system

.

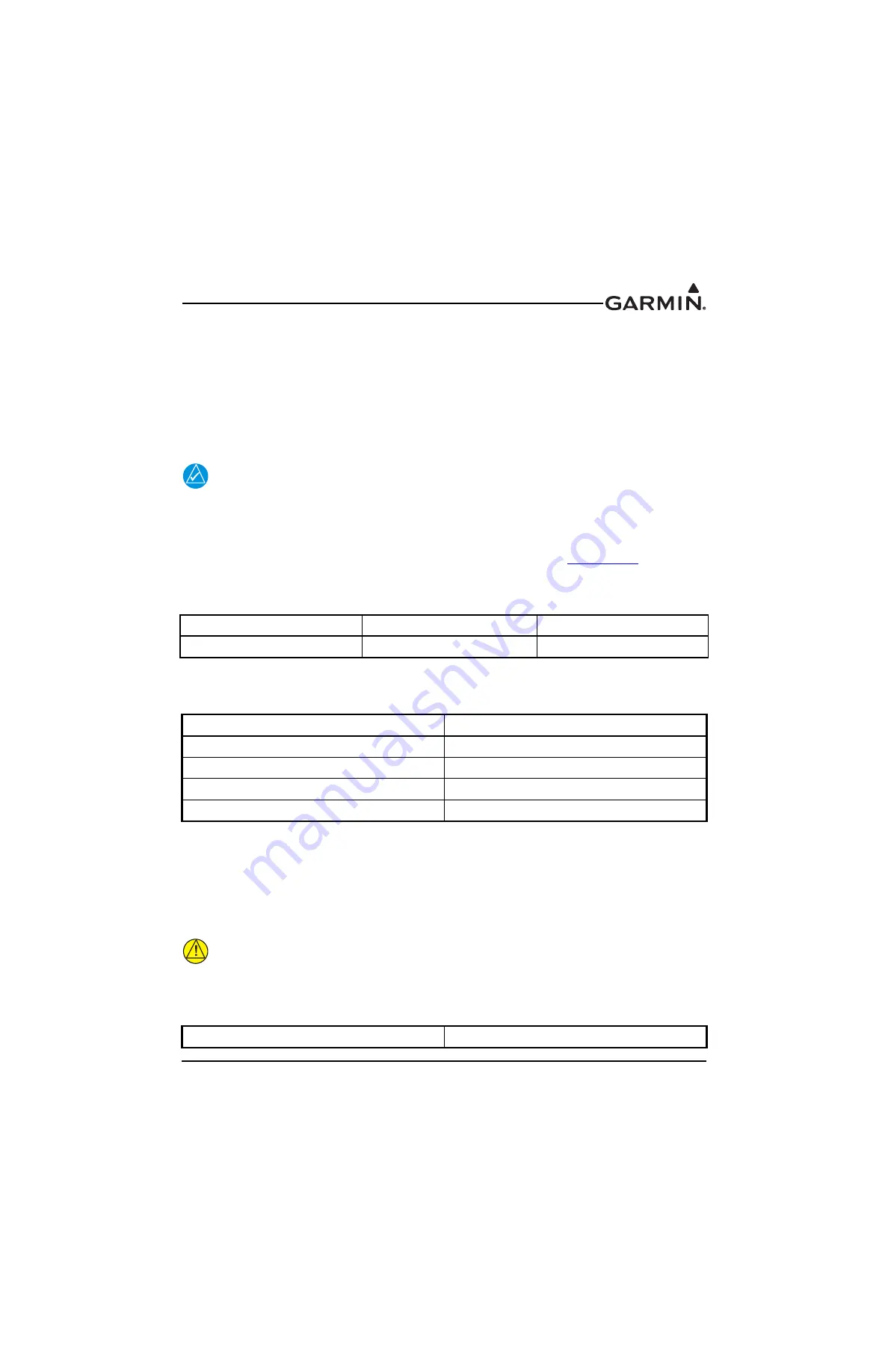

Table 17-1 GSA 28 Part Numbers

Model

Assembly Part Number

Unit Only Part Number

GSA 28 Servo Actuator, Unit Only

010-01068-00

011-02927-00

Table 17-2 General Specifications

Characteristic

Specification

Height

4.0 inches (10.16 cm)

Width

2.5 inches (6.35 cm)

Depth

2.8* inches (7.11 cm)

Weight

1.40** lbs, (0.635 kg)

*Harness connector not included

**Accessories not included

Table 17-3 GSA 28 Power Specifications

Supply Voltage

Current Draw