190-01115-01

G3X/G3X Touch Installation Manual - Engine/Airframe Sensor Installation

Rev. AC

Page 23-22

23.3.6 RPM (Revolutions Per Minute)

UMA 1A3C-2, UMA 1A3C-4 -

Standard mechanical tach drive sensor (0 – 5 volt square wave, 2 pulses per

crankshaft rev)

UMA N/T1A9-X, JPI 4208XX -

Magnetic pickup tach sensor (installed on mag bleed port)

Electronic Ignition -

Tach signal output at 1, 2, 3, or 4 pulses per revolution.

Jabiru Alternator -

Direct connection to alternator output (6 pulses per revolution)

Rotax Trigger Coil RPM Sensor -

This RPM sensor is applicable to Rotax engines. Refer to Rotax

Installation Instructions for complete installation details.

NOTE

Aircraft with dual electronic ignition systems can connect the tachometer signal output

from the second ignition to the

GEA 24/

). The value

displayed on the RPM gauge will be the higher of the two RPM signals.

NOTE

Electronic ignition systems with open-collector tachometer signal outputs may require a

pull-up resistor between the tachometer signal output and +5VDC or +12VDC.

23.3.6.1 Lycoming and Continental Engine Sensor Installation

General Installation Guidance

Electronic Ignition

-

Refer to vendor documentation for proper installation.

UMA 1A3C-2, UMA 1A3C-4

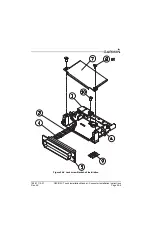

1. Remove the cap from the tachometer drive output (Figure 23-12) from the back of the engine.

2. Insert adapter tang into slotted keyway in sensor drive port.

3. Screw tach sensor onto threaded driver port, ensuring that the adapter tang on the sensor aligns

with the slotted keyway in the drive port (Figure 23-13).

4. Connect the supplied connector to the appropriate inputs on the GEA 24/GSU 73 as referenced in

the G3X interconnects in

. Secure the connector and wire assembly to an appropriate

location in the engine compartment to provide strain relief.

NOTE

The body of the sensor unit can be offset slightly to eliminate potential interference with

other engine accessories. If the interference cannot be alleviated by offsetting the sensor

directly, the builder may either install a magnetic pickup sensor or use a short tachometer

drive extension cable to remote mount the sending unit to the engine mount (or other

suitable location).