190-01115-01

G3X/G3X Touch Installation Manual - GSA 28 Installation

Rev. AC

Page 17-40

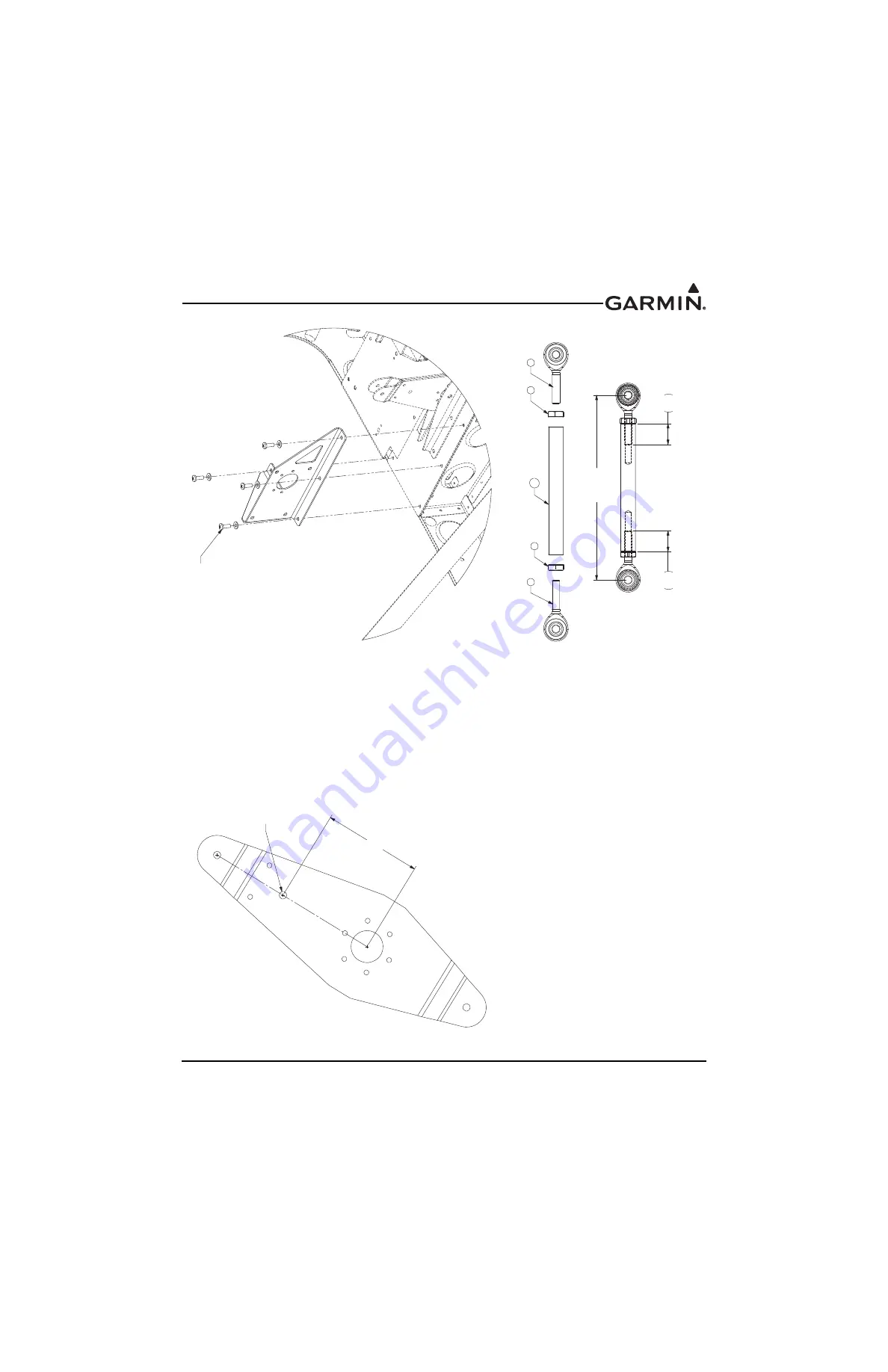

Figure 17-14.1 GSA 28 RV-10 Pitch Mounting Kit 011-02952-15 (page 2 of 2)

4.69

SEE NOTE 3

.531

.531

SEE NOTES 1 & 2

8

8

9

9

10

4

ET

O

N

E

E

S

4

ET

O

N

E

E

S

NOTE:

MOUNTING BRACKET SHOULD BE FASTENED TO AIRFRAME PRIOR TO INSTALLING SERVO.

1.

HOLES IN SERVO MOUNTING BRACKET ALIGN WITH EXISTING HOLES IN AIRFRAME. REMOVE

2.

FASTENERS FROM THESE HOLES TO MOUNT BRACKET TO AIRFRAME. RE-USE THESE FASTENERS

TO ATTACH SERVO BRACKET. TIGHTEN PER

AIRFRAME MANUFACTURER'S SPECIFICATION.

3. FOR BEST AUTOPILOT PERFORMANCE,

ANGULAR TRAVEL OF THE GSA28 SHOULD BE

MAXIMIZED. IT IS HIGHLY RECOMME

NDED THE GSA28 STOP BRACKET BE USED TO AVOID AN

OVER-CENTER CONDITION. WITH THE

GSA28 STOP BRACKET INSTALLED, IT IS RECOMMENDED

THE SERVO CRANK ARM STOPS JUST SHORT OF HITTING THE STOP BRACKET AT FULL TRAVEL IN

BOTH DIRECTIONS. BEST CASE SCENARIO

WOULD BE TO ACCOMPLISH THIS WITH THE PUSH ROD

ATTACHED TO THE OUTERMOST HOLE.

AIRCRAFT ATTACHMENT POINTS AND PUSH ROD LENGTH

SHOWN IN DETAIL 'C' AND 'E' ARE FO

R GUIDANCE ONLY. DEVIATE AS NECESSARY TO INCREASE

SERVO TRAVEL. IF ANGULAR SERVO

TRAVEL CANNOT BE MAXIMIZED USING THE OUTERMOST

HOLE IN SERVO, USING THE MIDDLE HOLE IS RECOMMENDED PROVIDED THERE IS NO RISK OF

CREATING AN OVER-CENTER CONDITION.

4. THREAD ENGAGEMENT BETWEEN ROD EN

D BEARINGS (ITEM 8) AND ALUMINUM PUSH ROD

(ITEM 10) MUST NOT BE LESS THAN 0.375".

DETAIL 'C'

DETAIL 'D'

DETAIL 'E'

HOLE FOR AN3 BOLT

(#12 DRILL SIZE)

2.50

SEE NOTE 3