190-01115-01

G3X/G3X Touch Installation Manual - Installation Preparation

Rev. AC

Page 2-22

2.3.1.3.4 CAN Bus LRU Removal Guidelines

The following should be considered when removing an LRU from the ends of G3X CAN network:

•

GEA 24, GSU 25, GAD 29, GPS 20A, G5, or other devices that uses the 9-pin CAN termination

adapter: The CAN bus will remain terminated as long as the CAN termination adapter is left

connected.

•

GDU 37X, GDU 4XX, GAD 27, or GSU 73: The CAN bus will be unusable until the LRU is

reconnected, or the bus is properly terminated at both ends of the CAN backbone.

•

GSA 28: A removal adapter (part number 011-03158-00) is provided with each GSA 28 connector

kit. This adapter can be used when a GSA 28 is removed from the aircraft. The removal adapter

keeps the node on the CAN bus in the same state as when the servo was installed (either terminated

or un-terminated). The removal adapter also allows trim signals to pass through when no servo is

installed.

2.3.1.3.5 CAN Bus Installation Guidelines

For maximum reliability of the CAN bus, the following guidelines should be followed:

•

The CAN bus backbone must be a single linear path with exactly two distinct ends. CAN bus

connections should be “daisy chained” from device to device. Avoid “star” and “Y” topologies,

and do not use a hub device (see

).

•

The overall length of the bus should not exceed 20 meters (66 feet).

•

Keep all stub node connections as short as practical. The maximum length of any stub node

connection is 0.3 meters (1 foot).

•

Avoid connecting more than one device to the CAN bus backbone at the same point. Instead, daisy

chain the CAN bus backbone from one device to the next.

•

Observe proper wiring, shielding, and grounding requirements described in section

.

•

Terminate the CAN bus at the two extreme ends of the bus, as described in

.

•

When adding a new device to the CAN bus, evaluate proposed modifications to the CAN bus

wiring connections to ensure compliance with all above requirements.

2.3.1.3.6 CAN Bus Troubleshooting

CAN is very simple, and a properly installed CAN bus is normally very reliable. If problems are

occurring, there is a good reason and the following steps can help to identify the issue.

1. Review the status LED of devices on the CAN bus such as the GSU25, GEA24, and GSA28 servos

(see

). The status indications are listed in Table 2-3.

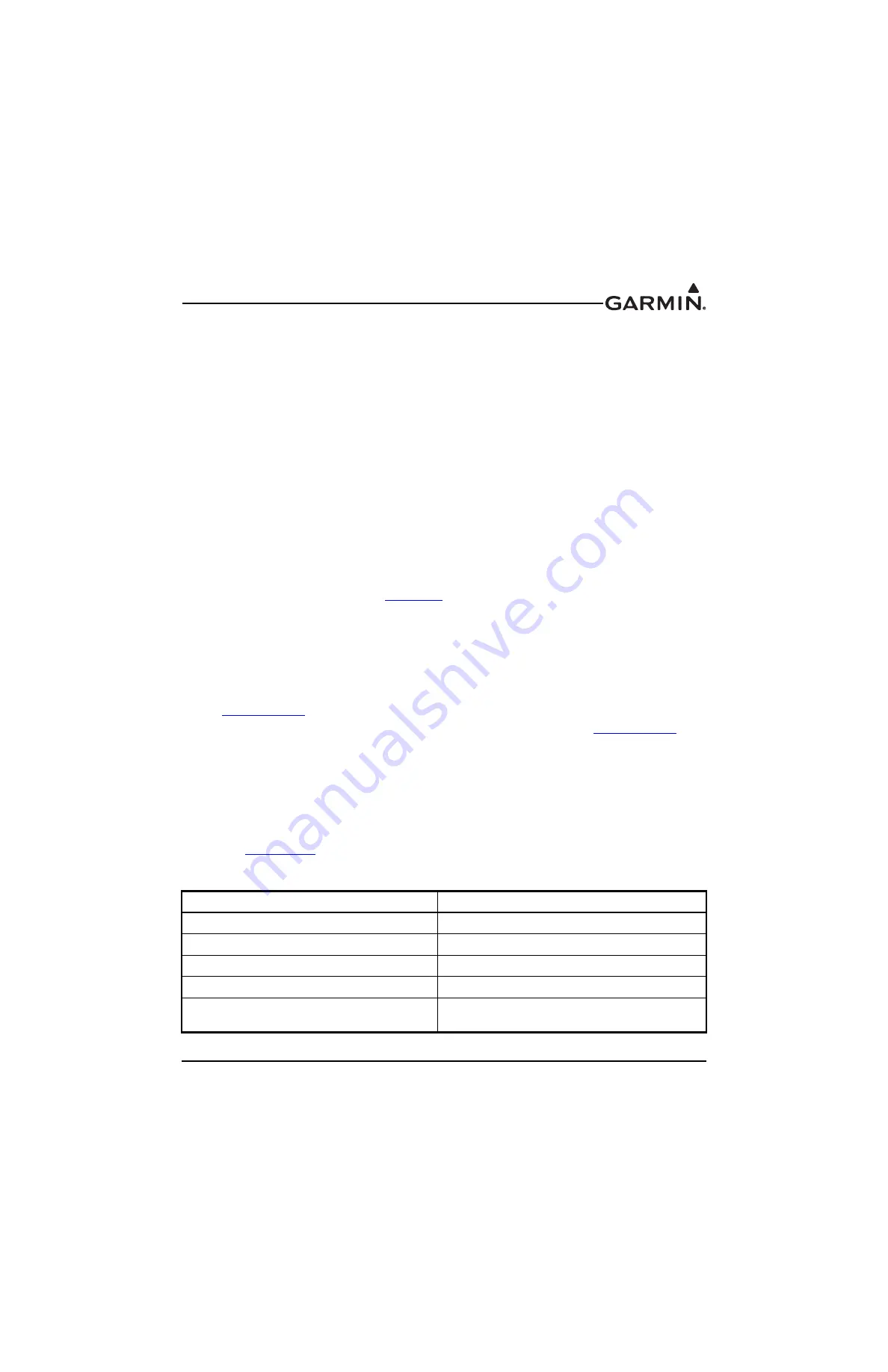

Table 2-3 Status LED Indications

LED Indication

Description

No Light

No Power

Steady Green

On, but not communicating via CAN Bus

Flashing Green

On and communicating via CAN Bus

Red

Hardware Fault

Alternating Red/Green

CAN bus network error two similar devices are

configured with the same unit ID