USER’S MANUAL

-

2

-

●

The end of the steel cable

(Fig. 3-1)

, which is fitted

with an M20 threaded shank (fixed with M20 nut and

lock nut, class 6S).

The length of the cables can be perfectly adjusted, also to

take up slack due to stretching, thanks to the length of the

threaded shanks on the ends of the cables.

Fig. 3

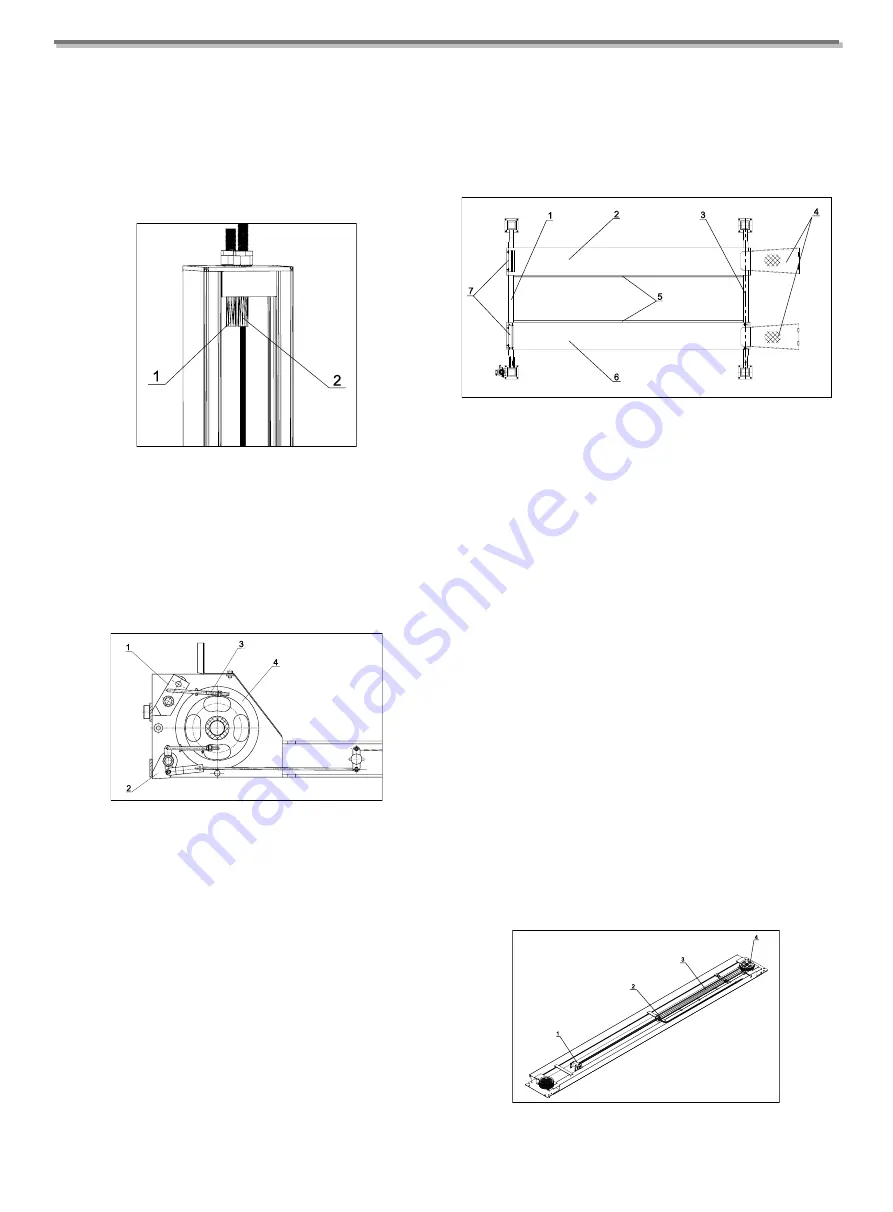

1.2 MOVABLE STRUCTURE

The movable structure consist of two cross-pieces and two

platforms.

Each cross-piece translates vertically between two posts.

Fig. 6

As shown in

Fig.6

, the ends of the cross-pieces are fitted

with the following parts:

●

Return pulleys

(Fig. 6-4)

for the lift cable

●

Mechanical safety devices (wedges)

(Fig. 6-1 and

Fig. 6-2)

The wedge

(Fig. 6-2)

will engage automatically during

lifting and when the lift is raised. To start the LOWERING

cycle the wedges must be disengaged by hand or using an

electro-pneumatic control (optional) when lowering.

The safety wedge

(Fig. 6-1)

take the weight in the event

of a cable failure; the wedge automatically engages with

the safety rods and immediately stops the movable section

of the lift together with the vehicle; the cable micro-switch

disconnects the electrical parts.

The two platforms

(Fig. 7)

are supported on the cross-

pieces.

Fig. 7

The right platform

(Fig. 7-6)

has no adjustment; the left

platform

(Fig. 7-2)

is free to slide across the width of the

lifting area to adapt to the track width of the vehicle being

lifted.

Both platforms have inside rails

(Fig. 7-6)

for rolling jack,

and fixed wheel stops

(Fig. 7-7)

to stop the vehicle from

going beyond the ends of the platforms.

The access ramps

(Fig. 7-4)

, pivoted to the platforms,

automatically reach a vertical position when the platforms

lift, thereby securing the vehicle also from the access end.

The following components are located beneath the fixed

platform

(Fig. 8)

, and are accessible only from underneath:

●

Hydraulic lift cylinder

(Fig. 8-3)

●

Parachute safety valve

(Fig. 8-2)

●

Clevis coupling

(Fig. 8-1)

for the steel cables

●

Two cable return pulley assemblies

(Fig. 8-4)

Fig. 8

Summary of Contents for TFA4500-3D

Page 2: ......

Page 4: ...USER S MANUAL ii...

Page 7: ...USER S MANUAL 3 Chapter 2 SPECIFICATIONS 2 1 OVERALL DIMENSION TFA4500 3D...

Page 8: ...USER S MANUAL 4 TFA5000 3D...

Page 9: ...USER S MANUAL 5 TFA5500 3D...

Page 10: ...USER S MANUAL 6 TFL5000 3D...

Page 31: ...USER S MANUAL 27 APPENDIX B HYDRAULIC DIAGRAM...

Page 32: ...USER S MANUAL 28 APPENDIX C ELECTRICAL WIRING DIAGRAM C 1 380V ELECTRICAL WIRING DIAGRAM...

Page 33: ...USER S MANUAL 29 C 2 220V ELECTRICAL WIRING DIAGRAM...

Page 35: ...USER S MANUAL 31 EXPLOSIVE DIAGRAM...

Page 36: ...USER S MANUAL 32...

Page 37: ...USER S MANUAL 33...