WARNING!

Ensure the blade teeth rotate in the correct direction

(see the arrow on the flywheel safety guard—Fig.6)

·

Tighten the band by means of the special handwheel

(3 Fig.10);

·

Close the flywheel safety guard and secure it with the

special clamps.

WARNING!

Ensure that the microswitch located under the

handwheel is pressed by the stop (1 fig.7) on the

handwheel otherwise the machine will not function.

The band is perfectly tensioned when the microswitch

is pressed by the stop of the handwheel. If the

flywheel safety guard is not properly closed the

machine does not work because of the safety

microswitch. (1 Fig.8)

THIS OPERATION MUST BE CARRIED OUT WHEN

THE MACHINE BOW IS IN STANDBY POSITION AND

THE SAW BLADE IS AT A STANDSTILL. DISCONNECT

THE MACHINE.

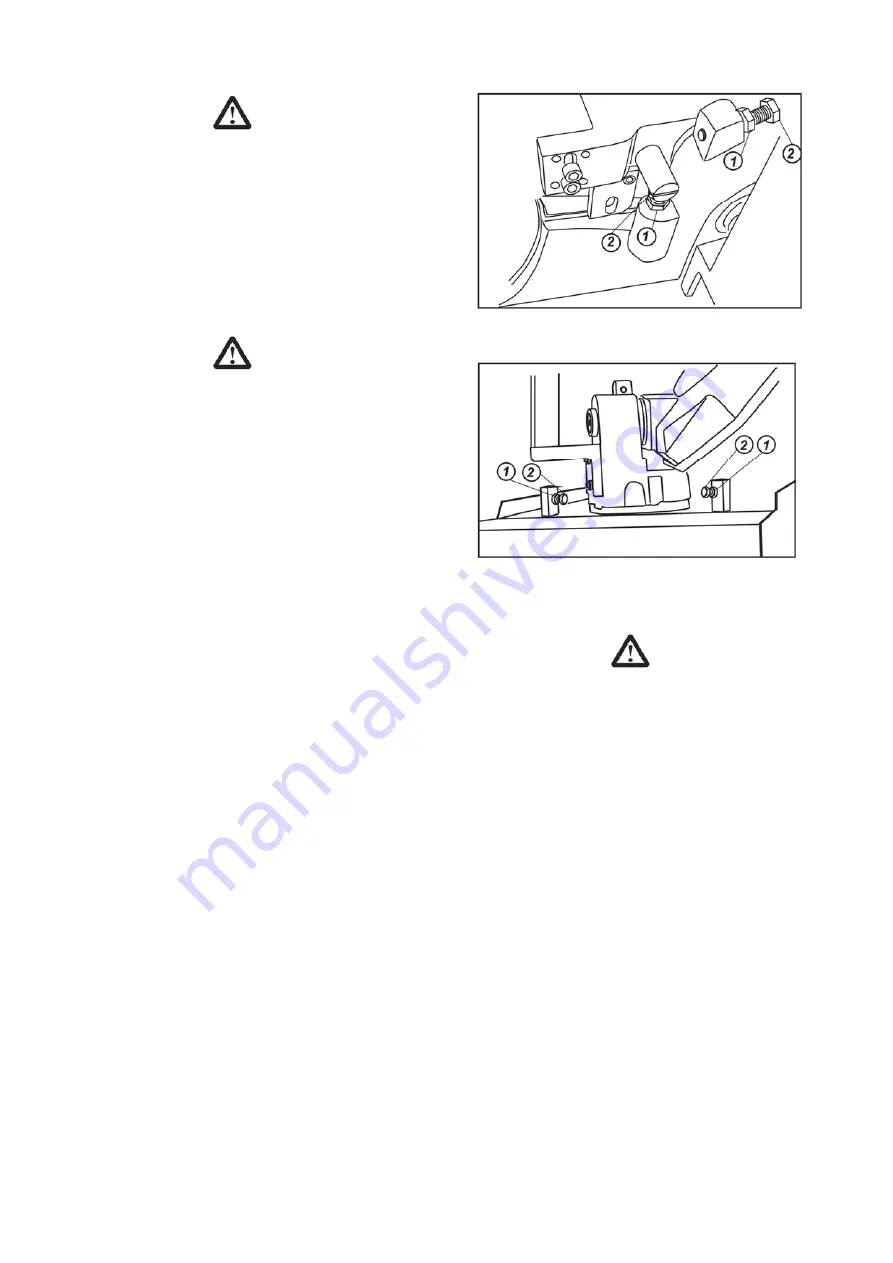

4.10 ADJUSTING THE BOW RETURN STROKE

It is possible to adjust the bow return stroke (this is a

useful operation if several repeated cuts are needed), in

this way the complete return stroke for each single cut be

avoided.

Proceed as follows:

·

Release the hex nut (1 Fig.11).

·

Screw in or out the hex bolt (2 Fig.11) to adjust.

·

Then tighten the hex nut.

Now the bow return stroke will stop at the set position.

4.11 ADJUSTING THE BOW PIVOT STROKE

The bow can pivots from 0

o

to 60

o

. To adjust the 0

o

and

60

o

, proceed as follows:

·

Release the hex nut (1 Fig.12).

·

Screw in or out the hex bolt (2 Fig.12) to adjust.

·

Then tighten the hex nut.

15

Fig.11

Fig.12

4.12 ADJUSTING THE FRONT BLADE GUIDE UNIT

WARNING!

This adjustment must be repeated every time the

section of the workpiece changes.

To get the maximum accuracy and safety during the cut

(i.e with a very small portion of blade not covered by the

guard) the blade guide unit must be as possible to the

piece to be cut.

Release the blade guide arm by operating the piece to be cut.

This way the arm will not make contact with the piece

during its stroke; then retighten the arm.

4.13 STOP THE SAW

To stop the saw band from rotating while operating simple

release the handgrip control (1 Fig.1).

The machine can also be brought to a stop by pushing the

emergency (6 Fig.1).

The machine can also be brought to a stop by turning the

total switch (8 Fig.1) to position “OFF” (or “0” ).

The machine can also stop when the cut I completed.

Summary of Contents for BS260

Page 5: ...4...

Page 6: ...5...

Page 18: ...17...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...NOTES Page 27...

Page 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...