PART LIST

Part

NO.

Description Size

No.

Qty

Part

NO.

Description Size

No.

Qty

75 Emergency

Switch

1 107 Nut

M12

1

76

Main Connect Switch

1

108

Handle

1

77

Power Indicator Light

1

109

Hex. Socket Cap Screw

M10 x 30

4

78

Hex. Socket Cap Screw

M5 x 8

4

110

Spring Washer

10

4

79 Washer

5

2 111 Gib

1

80

Hex. Socket Cap Screw

M5 x 8

2

112

Spring Washer

8

6

81

Cover

1

113

Hex. Socket Cap Screw

M8 x 20

6

82

Hex. Socket Cap Screw

M5 x 8

4

115

Front Ball Bearing Bracket

1

83

Control Box Bottom Plat

1

116

Set Screw

M6 x 12

1

83-1

Transformer

1

117

Hex. Socket Cap Screw

M8 x 25

2

83-2

Contacts

1

118

Hex. Socket Cap Screw

M12 x 50

1

83-3

Fuse Seat

1

119

Setting Bracket

1

83-4

Overload Rely

1

120

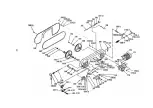

Hex. Socket Cap Screw

M6x 8

2

83-5

Magnetic Connector

1

121

Plastic Handle

1

84

Control Box Bottom Part

1

122

Hex. Socket Cap Screw

M6x 8

2

85-H Control Box Panel

1

123

Cover Plate

1

85-H1

Manual/Auto Selector

1

127A

Slide

1

86 Support

1

127A-1

Spring Washer

10

3

88

Hex. Socket Cap Screw

M5 x 8

4

127A-2

Hex. Socket Cap Screw

M10 x 45

3

89

Hex. Socket Cap Screw

M8 x 20

2

127A-3

Set Screw

M10 x 16

1

90 Spring

Washer

8

2 128 Nut

M16x2.0x8t 1

91 Setting

Bracket

1 131 Handle

2

92

Spring Washer

8

4

132

Handle Wheel

1

93

Hex. Socket Cap Screw

M8 x 20

4

133

Thrust Spring Washer

10

94 Swivel

Arm

1 134 Tension

Shaft

1

94-1

Scale

1

137

Set Screw

M8 x 25

2

94-2 Rivet

2mm

2

138 Rod

1

95 Disk

1 139 Nut

M16x2.0x8t 1

140

Trigger

Switch

1

97 Oil

Seal

1 141A

Shaft

1

98 Shaft

1 142 Ball

Bearing

#32006zz 2

99 Nut

1 143 Idle

Flywheel

1

100

Hex. Socket Cap Screw

M8 x 25

4

101

Spring Washer

8

4

145

Star Washer

30

1

102

Set Screw

M8 x 10

1

146 Jam

Nut

M30

1

103

Hex. Socket Cap Screw

M10 x 35

1

147

Oil Inlet

1

104 Spring

Washer

10

1 148 Saw

Arm

1

105

Set Screw

M10 x 10

1

149

Blade Cover

1

106

Locking Lever

1

150

Knob Bolt

M6 x 10

4

19

Summary of Contents for BS260

Page 5: ...4...

Page 6: ...5...

Page 18: ...17...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...NOTES Page 27...

Page 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...