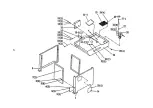

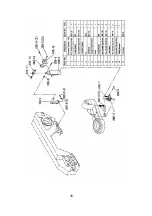

PART LIST

Part

NO.

Description Size

No.

Qty

Part

NO.

Description Size

No.

Qty

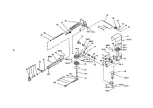

151

Round Head Screw

M4 x 8

2

176

Spring Washer

8

4

153 Spring

Washer

4

2 177 Hex. Cap Bolt

M8 x 30

4

154 Nut

M4

2 178 Gear

Box

1

155

Hex. Cap Bolt

M10 x 25

1

178-1

Vent Screw

1

156

Spring Washer

10

1

178-2

Key

8 x 8 x 35

1

157

Washer

1

179

Set Screw

M6 x 12

4

158

Drive Flywheel

1

180

Spring Washer

8

2

159

Hex. Socket Cap Screw

M10 x 40

4

181

Hex. Socket Cap Screw

M8 x 25

2

160

Spring Washer

10

4

182

Front Blade Guard

1

161

Hose

5/16” x(100cm)

1

183

Round Head Screw

M6 x 8

3

184

Set Screw

M6 x 6

4

163

Pipe Fitting Seat

1

185

Bolt

2

164

Hex. Socket Cap Screw

M5 x 30

2

186

Front Ball Bearing Seat

1

165

Coolant Switch

1/4P x x5/16

1

187

Pipe Fitting

1/4P x x5/16

1

166

Hose Clamp

1

188

Rear Blade Guard

1

189

Blade

Guide(B)

2

168

Hose

5/16(40cm)

1

190

Hex. Socket Cap Screw

M6 x 8

2

169

Saw Arm

1

191

Rear Ball Bearing Seat

1

169-1 Plate

1

192

Pipe Fitting

1/4P x x5/16

1

169-2 Switch

1

193

Set Screw

M6 x 20

2

169-3 Screw

M4 x 30

2

193-1

Nut

M6

2

169-4 Washer

4

2

194 Hex. Cap Bolt

M6 x 12

2

170

Limit Switch

1

195

Nut

M6

1

170-1 Switch Pin

1

196

Screw

M6 x 25

1

171

Hex. Socket Cap Screw

M4 x 35

2

197

Set Nut

M6

1

172-H1

Spring Shaft

1

198

Bracket

1

172-H2

Adjust Plate

1

199

Brush

1-1/2”

1

172-H3

Handle

1

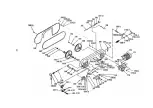

200

Eccentric

Shaft

2

172-H4

Nut M16x2.0x8t

1

201

Ball

Bearing

#608zz

8

172-H5

Hanger

1

202

Blade

Guide(A)

2

172-H6

Lead Screw

1

203

Hex. Socket Cap Screw

M6 x 25

2

172-H7

Spring

1

204

E

Ring E7

4

172-H8

Set Screw

M8 x 10

1

205

Centric Shaft

2

174

Key

8 x 8 x 35

1

206

Ball Bearing

#608zz

2

175

Motor

1

20

Summary of Contents for BS260

Page 5: ...4...

Page 6: ...5...

Page 18: ...17...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...NOTES Page 27...

Page 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...