ANITA ©

Serie GF-105

14

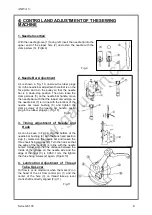

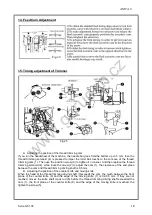

10. Height and Tension Adjustment of Presser Foot

A. Aa is Fig.19, remove the rubber plug

(2) in the face plate and place the

presser foot (3) on the needle plate.

Then, loosen the presser bar fixing

screw (4) and adjust the height of

the presser bar. The presser foot

lifter (3) will fall when the presser

bar is lifted and rise when the

presser bar is moved down. Move

the presser foot lifter (5) manually to

place the bottom face of the presser

foot 5,5 mm above the top face of

the needle plate and tighten the

presser bar fixing screws firmly.

B. The tension of the presser foot will

grow stronger when the tension

adjusting screw (6) is turned

clockwise and turned clockwise and

weaker when turned counterclockwise. Make sure to screw in the fixing nut (1) after adjustment.

(Fig.19)

C. Loosen set screw (1) and adjust the presser bar height or the angle of the presser foot. After

adjustment, securely tighten the setscrew.

Fig

. 19a

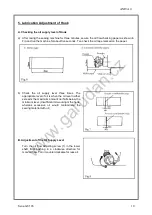

11. Adjustment of Automatic Knee-Lifter

An automatic knee-lifter will be attached to the sewing machine at point of delivery. The lifting amount

of the presser foot when automatically lifting the knee is controlled by the automatic knee-lifting

solenoid shaft crank (1). First, loosen the solenoid cover fixing screw (3) and remove the solenoid

cover (2). If the solenoid shaft (5) is moved left and the fixing screw (4) is tightened when the solenoid

crank shaft fixing screw (4) is loose, the amount of the presser foot grows smaller. If the solenoid shaft

(5) is moved to the right, the lifting amount will grow bigger. Assemble the cover back after the

adjustment is completed. (the presser foot lifting amount for the automatic knee-lifter will be set to 13

mm by default at point of delivery).

Fig.20

Fig. 19

www.garudan.cz

Summary of Contents for GF-105 Series

Page 4: ...ANITA Serie GF 105 4 2 w w w g a r u d a n c z...

Page 5: ...ANITA Serie GF 105 5 w w w g a r u d a n c z...

Page 6: ...ANITA Serie GF 105 6 3 INSTALLATION 1 Before operation w w w g a r u d a n c z...

Page 22: ...ANITA Serie GF 105 22 5 NOTES w w w g a r u d a n c z...

Page 23: ...ANITA Serie GF 105 23 6 SPARE PARTS LIST w w w g a r u d a n c z...