1. Safety instruction

Please read the operation manual and related sewing machinery datasheet carefully before correct use.

1.1 (1) Power voltage and frequence: please refer to motor and control box nameplate.

(2) Interference from electromagnetic wave:please keep far away strong magnetic or high radiation environment in order

to avoid obstructions and make to misoperation.

(3) Grounding: to avoid the noise obstructions or leakage of electricity accident(inculding sewing machine,motor,control

box and positioner).

1.2 Please make sure power off at least 1min and then can open control box cover, because there are dangerous high voltage.

1.3 Please turn off the power while repairing or wearing needle in order to protect operater’s safty.

1.4

Used where potential dangers exist.

Used where high voltage and electric danger exist.

1.5 Product warranty period of one year on condition that this machine is operated correctly and no man-made damage.

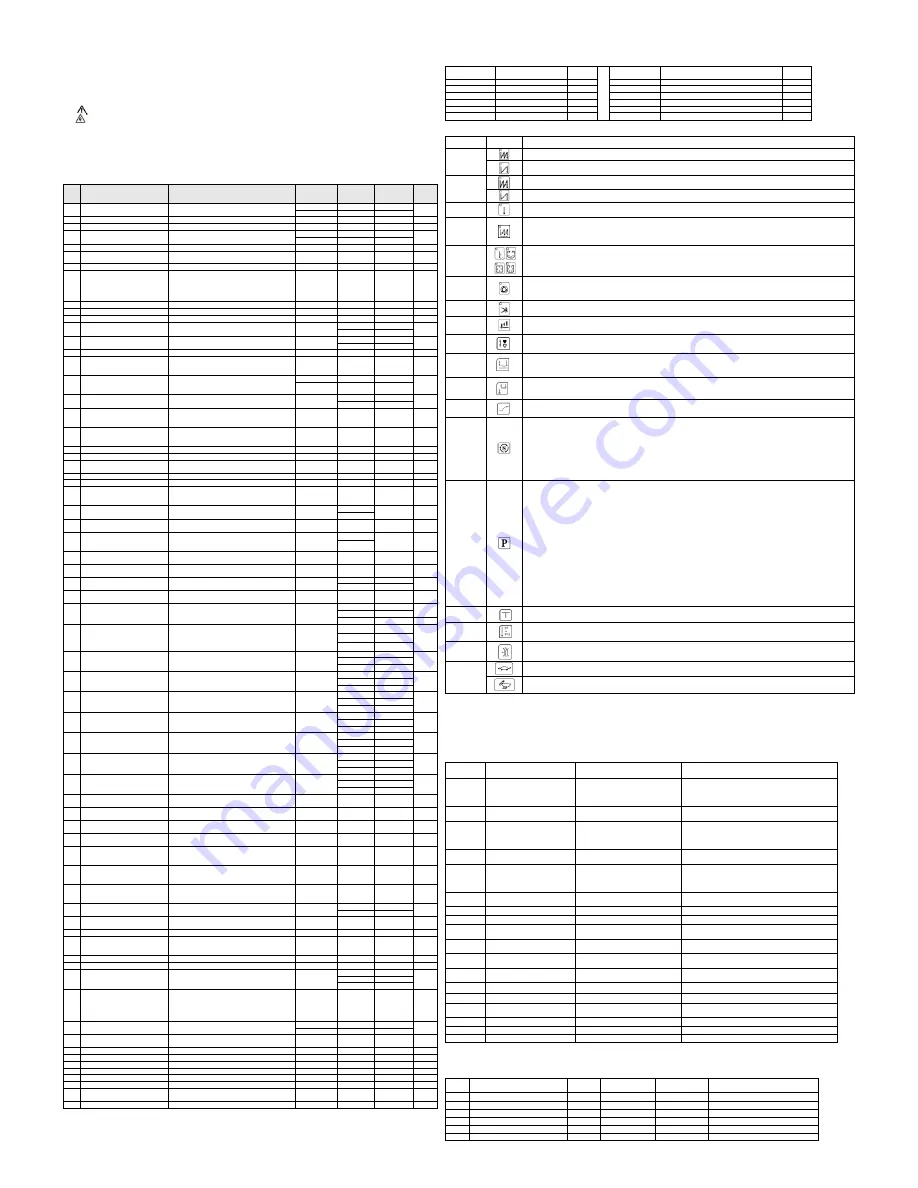

No

Project

Content

Setting

range

The

default

value

model

Level

1

Sewing speed

Set sewing speed

200~5000rpm

3700

ABCDGIL

I

200~3500rpm

3000

EFHJKN

2

Soft-start function

1~9: Soft start stitches

1~9

1

All

I

3

Ornamental bartacks

0: Invalid 1: Effective

0/1

0

All

I

4

Fixed-length seam sewing speed

Set fixed-length seam sewing speed

200~4000rpm

3000

ABCDGIJL

I

200~3500rpm

2500

EFHKN

5

Simple sewing mode Settings

0: invalid 1: effectively

0/1

0

All

I

9

Back stitch speed limitation

can keep needle from breaking while

backstitching

500~1500rpm

800

All

I

19

Solid after before sewing stop

0: unavailable 1: available

0/1

0

All

I

20

Setting of reverse sewing switch

function

Reverse sewing switch mode

0: Only reverse sewing

1: Reverse sewing and fill needle

2: Only reverse sewing, standby without operating

0/1/2

0

All

I

21

soft start speed 1

speed of the 1

st

needle of soft start

100~3000rpm

400

All

I

22

soft start speed 2

speed of the 2

nd

needle of soft start

100~3000rpm

1000

All

I

23

soft start speed 3

speed of the 3

rd

~9

th

needle of soft start

100~3000rpm

1500

All

I

24

Presser foot soft lowering

function

0: unavailable 1: available

0/1

0

ABCDEFGHIJK

I

1

LN

25

Presser foot lift function

0: unavailable 1: available

0/1

0

ABCDEFGHIJK

I

1

LN

27

Power on and positioning

0: unavailable 1: available

0/1

1

All

I

28

signal mode for turn/lift switch

Setting of signal mode of turn/lift switch of

machine head 0: always open

1: always close 2:forbid a protection

0/1/2

0

All

I

29

Presser foot soft lowering time

To set presser foot soft lowering time

The longer time the lower speed of the presser

foot

50~500ms

300

ABCDEFGHIJK

II

10~500ms

50

LN

32

Decorative bar-tacking dwell

time

To set decorative bar-tacking dwell time

5~500ms

50

ABCDGIJL

I

100

EFHKN

34

To select standard bar-tacking

pedal speed mode

Standard bar-tacking pedal speed

Mode selection

0:Auto bar-tacking speed ; 1:Pedal speed

0/1

0

All

II

35

By-piece rate setting

0:No by-piece function

1~20:Plus 1 to by-piece value for each set thread

trimming

0~20

1

All

I

37

Thread wiping operation time

Thread wiping operation time

0~800ms

40

All

II

41

Low speed

The lowest speed of pedal

100~400rpm

200

All

I

42

Pedal curve selection

Pedal speed adjustment 0:normal

1:Slow acceleration 2: Quick acceleration

0/1/2

0

All

I

43

Dial the line that can set

0: unavailable 1: available

0/1

1

All

I

44

thread-cutting speed

thread-cutting speed

100~400rpm

280

All

I

45

Reverse sewing speed limit switch

Reverse sewing speed limit switch processing can

prevent reverse sewing needle breakage

0: infinite speed 1: have the speed limit

0/1

0

All

I

46

pressor foot lifting delays

sewing

delay with pressor foot lowered

0~800ms

200

ABCDEFGHIJK

LN

II

100

47

output time of total pressure of

pressor foot lifting

output time of total pressure of pressor foot

lifting

0~800ms

150

All

II

48

output duty cycle of pressor foot

lifting

hold time of pressor foot lifting

output duty cycle of pressor foot lifting

forced shut-down after hold time of pressor foot

lifting

0~100

30

All

II

40

49

output duty cycle of pressor foot

lifting

output duty cycle of pressor foot lifting

1~60(s)

12

All

II

50

output time of total pressure of

reverse-sewing

output time of total pressure of reverse-sewing

0~800ms

150

All

II

51

output

duty

cycle

of

reverse-sewing

output duty cycle of reverse-sewing

0~100

40

ABEFGHJKLN

II

35

CDI

52

hold time of reverse-sewing

forced

shut-down

after

hold

time

of

reverse-sewing

1~60(s)

12

All

II

53

starting

reinforcing-sewing

speed

starting reinforcing-sewing speed

100~3000rpm

1800

ABCDGIL

I

1200

EFHN

500

JK

54

starting

reinforcing-sewing

compensation 1

parameter of starting reinforcing-sewing stitch

compensation

0~100

30

ABGJL

I

35

CDI

58

EFHNK

55

starting

reinforcing-sewing

compensation 2

parameter of starting reinforcing-sewing stitch

compensation

0~100

10

ABGJL

I

24

CDI

18

EFHKN

56

ending reinforcing-sewing speed

ending reinforcing-sewing speed

100~3000rpm

1800

ABCDGIL

I

1200

EFHN

500

JK

57

ending

reinforcing-sewing

compensation 1

parameter of ending reinforcing-sewing stitch

compensation

0~100

30

ABGJL

I

35

CDI

58

EFHKN

58

ending

reinforcing-sewing

compensation 2

parameter of ending reinforcing-sewing stitch

compensation

0~100

10

ABGJL

I

24

CDI

18

EFHKN

59

ending reinforcing-sewing speed

ending reinforcing-sewing speed

100~3000rpm

1800

ABCDGIL

I

1200

EFHN

500

JK

60

continuous

reinforcing-sewing

compensation1

parameter of continuous reinforcing-sewing

stitch compensation

0~100

30

ABGJL

I

35

CDI

58

EFHKN

61

continuous

reinforcing-sewing

compensation2

parameter of continuous reinforcing-sewing

stitch compensation

0~100

10

ABGJL

I

24

CDI

18

EFHKN

62

Pedal travel upon start

Pedal position upon start

Travel relative to medium pedal

10~50

(0.1°)

25

All

II

63

Pedal travel upon acceleration

Pedal position upon start acceleration

Travel relative to medium pedal

10~100

(0.1°)

50

All

II

64

Pedal travel at highest rotation

speed

Pedal position at highest rotating speed Travel

relative to medium pedal

10~150

(0.1°)

110

All

II

65

Pedal travel upon presser foot

lift

Pedal position upon pedal lift

Travel relative to medium pedal

-100~-10

(0.1°)

-30

All

II

66

Pedal travel upon presser foot

lowering

Pedal travel from presser foot lowering position

to neutral position

Travel relative to medium pedal

5~50

(0.1°)

10

All

II

67

Pedal travel 1 upon thread

trimming

Pedal position upon start trimming without

presser foot function

Travel relative to medium pedal

-100~-10

(0.1°)

-30

All

II

68

Pedal travel 2 upon tread

trimming

Pedal position upon start thread trimming with

presser foot function

Travel relative to medium pedal

-100~-10

(0.1°)

-60

All

II

69

Down needle positioning position

To adjust down needle position

120~240

175

ABEFGHJKLN

I

177

CDI

70

Reverse needle lift function

Reversal of needle lift function after thread

trimming 0: unavailable 1: available

0/1

0

All

I

71

Reversal of needle lift angle

Reversal of needle lift angle

0~45°

20

All

I

72

Thread clamp strength adjustment

Adjust the thread clamp strength size

0: Clip line function is invalid

1~9: Three Intensity Adjustment

0~9

7

All

I

73

Thread pressing actuation angle

Thread pressing actuation angle

10~150°

100

All

I

74

Thread pressing release angle

Thread pressing release angle

160~300°

270

All

I

75

Needle position adjustment

Needle position adjustment

0~240°

105

ABEFGHJK

I

112

LN

165

CDI

79

return to factory-set parameter

5: restore the current level factory parameters

8: restore the current level and sewing factory

parameter set

According to S button, select yes, then press the

S key execution

0~15

0

All

I

80

highest speed of sewing

highest speed of sewing

300~5000spm

4000

ABCDGIL

II

300~3500spm

3000

EFHJKN

83

Aggravating function/

Machine needle emphasis function

Needle wear through cloth when used

0: invalid; 1 ~ 15 strength regulation

0~15

0

ABCDEFGHIJ

II

84

Aggravating function

0: invalid; 1 ~ 15 strength regulation

0~15

0

LN

II

85

Suction angle of shear line

To set suction angle of shear line

150~200

175

All

II

86

Power angle of shear line

To set power angle of shear line

200~300

260

All

II

87

Release angle of shear line

To set release angle of shear line

300~360

340

All

II

88

loosen pressing actuation angle

loosen pressing actuation angle

150~250

180

I

I

89

loosen pressing release angle

loosen pressing release angle

200~360

350

I

I

92

Pedal presser foot lift confirm

time

Pedal presser foot lift confirm time

10~300ms

80

All

II

93

The neutral position of the pedal

Trimming the neutral position of the pedal

-15~15(0.1)

0

All

II

95

dial line / clip line Type

selection

Type selection;0:dial line 1:clip line

0/1

0

ABCDEFIJK

II

1

GHLN

2. System parameter table

A:587/586(Full automatic integrated Digital version) B:587C/CD(Full automatic integrated Liquid crystal version)

C:588(Full automatic Less oil integrated Digital version) D:588C/CD(Full automatic Less oil integrated Liquid crystal version)

E:587H/586H(Full automatic Thick material integrated Digital version) F:587CH(Full automatic Thick material integrated Liquid

crystal version) G:587C/CD(Full automatic integrated Liquid crystal version Public models) H:587CH/CHD(Full automatic Thick

material integrated Liquid crystal version) I:589( Full automatic Less oil 9813 Liquid crystal version)

L:587Y(Fully automatic machine pressure foot built-in) N:587YH(Fully automatic

Thick material machine pressure foot built-in)

5. Error codes

Error

Code

Contents

Possible reasons

Checking and treatment

E011

E012

E013

E014

Motor signal error

Motor position sensor signal failure

If electric engine plug is well contacted;

if electric engine signal detecting device has been

broken;

if sewing machine handwheel correctly installed.

E015

Model type error

Unable identify operating box model

type

Check operating box

E021

E022

E023

Motor overload

motor stall

motor overload

If electric engine plug is well contacted;

if machine head or thread-cutting mechanism has been

blocked completely;f materials are too thick;

Electrical signal detection signal whether the normal.

E101

Hardware drivers fault

Current detection abnormal

Driving hardware error

Current

detection

loop

system

is

working

properly;Whether the damage to the device driver.

E111

E112

Voltage too high

High input voltage

Brake circuit fault

Voltage detection error

System into line voltage is too high;

Braking resistance are working properly;

System voltage detection circuit are working properly.

E121

E122

Voltage too low

Actual low voltage

Voltage detection is wrong

If the voltage on the inlet wire is too low Whether the

system voltage detection circuit the normal work.

E131

Current circuit fault

Current detection abnormal

Current detection loop system is working properly.

E133

Oz circuit fault

Oz circuit fault

Oz circuit system is working properly.

E151

Magnet circuit error

Over current magnet circuit

If machine head magnet suffers short circuit

Electromagnet circuit is working properly.

E201

over current

Current detection error

Current detection loop system is working properly

Electrical signal is normal.

E211

E212

Abnormal motor operation

Current or voltage detection error

If electric engine plug is well contacted;

If electric engine signal is matched.

E301

Communication error

Sci circuit error

if operation box plug is well contacted;

if operation box components are damaged.

E302

Operation inner failure

Sci circuit error

To check whether the operating box is damaged..

E402

Pedal ID fault

Pedal verification fault

Pedal connection is loosen.

E403

Pedal zero position fault

The pedal zero position over range

The pedal is damaged or it is not under stop state when

correction.

E501

Safety switch fault

Safety switch effective

Put down the head or check turned up switch.

P.oFF

Power off Display

Power off

Wait for power supply to resume.

EvaL

Trial expired

Trial expired

Contact the dealer processing

Note: 1. Sewing abnormal action (speed electromagnet work abnormal) : in the control interface view model is correct;

2. Turn up E501 fault when: sure it is normal to switch detection, temporary use can change the P-28 parameters;

3. If the above according to check the project cannot rule out fault, please seek technical support.

Function

Button

Described

Starting

reinforcing

-sewing

Execute starting reinforcing-sewing 2 times, to and fro.

Execute starting reinforcing-sewing 1 times, to and fro.

ending

reinforcing

-sewing

Execute ending reinforcing-sewing 2 times, to and fro.

Execute ending reinforcing-sewing 1 times, to and fro.

free-style

sewing

Press treadle ahead for normal sewing, stop in the middle, behind for thread-cutting and thread wiping.

continuous

reinforcing

-sewing

1、Press treadle ahead for automatic sewing, to and fro, which is set at D and can reach 15times.(F)

2、Continuous reinforcing-sewing is in trigger mode by default, treadle doesn’t need to be kept being pressed, and

corresponding trigger light of preset sewing is solid lit.

3、Previous ending reinforcing-sewing setting is invalid if this function is valid.

preset

sewing

1.Press treadle ahead to execute sewing times set at E or E, F, G, H.

2.Sewing will stop immediately if treadle is lifted; press treadle again, it will go on with the rest.

3.Ending reinforcing-sewing (if selected), thread-cutting and thread wiping will be automatically executed after sewing

is completed.

parameter

setting

1.For preset sewing. Trigger treadle and the system will automatically conduct sewing at E, F, G, H sections; the treadle

doesn’t need to be kept being pressed.2.Solid light for continuous reinforcing-sewing mode means that it is trigger mode

by default.

thread-cutt

ing

selection

Set or cancel thread-cutting function.

needle-lift

ing/stitch

compensatio

n

Free sewing mode, can be based on the according to the length of time is different, complementary half needle,

a needle or continuous feeding half needle.

Needle

position

Set the needle position shortcut keys,Key is effective for needle,The cancel key function is set to stop pin。

The middle

presser

foot

Presser foot to set shortcut keys: set or cancel the presser foot function.

Shear line

pressure

foot

The shear line and presser foot set shortcut keys: set or cancel trimmer and presser foot function.

Soft start

Soft start to set shortcut keys: set or cancel the pedal soft start function.

Pinnumberse

t/check

choice

1.Implementation of this key, circulating switch display 3 pin number to set the display value

upper end:A、B、C、DPeriod of pin number,Light corresponding level;

Middleend:E、FPeriod of pin number,Light corresponding level;

lower extreme:G、HPeriod of pin number,Light corresponding level;

2.Corresponding to A D period of pin number, can set range 0 ~ 15 needle, B paragraph C pin number, can set range 1 ~ 15

needle, among them, the liquid crystal display A B C D E F on each for 10 11 12 13 14 15 stitches.

3. To take the thread clamp function model, according to the buttons can show long thread clamp strength adjustment (3

bright lights and three, liquid crystal display [7]), again according to the key exit.

parameter

setting

1.Entering different parameter level

On the sewing setting interface, the user can press the button P to enter the Parameter Interface, then the Level I parameters

in the parameter list will display.

On the sewing setting interface, the user can keep pressing the button for a few seconds to enter the Password Entering

Interface. After entering the right maintenance password, then the user can press the button P to enter the Parameter

Interface, now the Level I and Level II parameters in the parameter list will display.

2.Password setting

On the sewing setting interface, the user can keep pressing the button P for a few seconds to enter the Password Entering

Interface, and press the button combination of “burst

soft start button” to enter the Password Resetting

Interface. The three indicators (respectively are Indicator S1, S2 and S3 from left to right/before three lamp, among which

one is on) corresponding to the button S indicates the current status. S1 lights up, old password input, ending the key

combination trigger key + tangent key, if the correct password into the password reset interface (mistakes have stayed

the S1 state), and at the same time S2 light, prompting the input new password and click confirm S3 S key input again when

the light is the new password, according to S key after two input if consistent, then set success, return to parameter

interfaceIf the new passwords entered are not the same, the Indicator S1 will be on and the LC screen will be reset, and

the user shall enter the old password again. If the user presses the button P, the user will be brought back to the interface

parameters and no modification will be saved. You can choose from the numbers of 0 to 9 or the letters of A to F for every

single character of the password. Please do keep the new password in mind.

Teaching

function

Set or cancel the teaching function. (for liquid crystal panel)

Sewing set

program

The number of needles sewing set,Set up a total of 15 segment needle number P1~PF. (for liquid crystal panel)

Clip the

line

intensity

set

Clip the line strength fast set

speed key

Speed down. Keeping pressing to lower speed, the display will automatically switch to speed set. Simple seam, free seam

effective.(Application of liquid crystal panel)

Speed up. Keeping pressing to increase speed, the display will automatically switch to speed set.Simple seam, free seam

effective. (Application of liquid crystal panel)

Teaching function:

In the long slot (a, four, program seam) mode, long press "T" one second, you can enter the teaching interface, this interface has buttons: T key,

two groups of add-substract key, fill needle key. Role is as follows:

Add-substract key 12: change teaching segments, segment numerical only to accumulate (into the next section teaching automatically save the last needle

numerical reduction), '-' key is invalid. Note: when the pedal operation, the key is invalid;

Add-substract key 34: modify teaching pin number, to stop running when the adjust pin number. Fill needle keys: press can manually fill needle, needle

change.

T: exit show interface, complete the current segment number teaching (section numerical covering the original mode).

After the pedal shear line, will directly from the show and save the needle numerical, before returning to the fixed length of stitch pattern.

6.Accessories

NO

Product name

Amount

Product

specification

Confirm

Remarks

1

Electric control box

1

2

Ball section connecting rod

1

3

pedal

1

PL-302

with bracket

4

screw

3

M5×25

screw

5

The instructions

1

6

power cord

1

3.System Info

Operation panel default mode, press the button at the same time in P made sewing needle trigger select key, enter the system

monitoring state through the +-key choose need to look at the project, according to the S button to enter/exit the selected

projects such as the need to exit monitoring interface, according to P keys can be.

4.Operation box use

Full automatic integrated sewing series manual V1.9

-1-

-2-

show frame

numbers

Item Name

unit

show frame

numbers

Item Name

unit

JJ

Plan number

piece

U6

Motor initial Angle

limit

U1

speed of motor control

rpm

U7

Master control program version/ Head type

/

U2

Motor Current

0.01A

U8

Head type/ Master control program version

/

U3

Motor Voltage

V

U9

Dsp no

/

U4

Pedal voltage

0.01V

vEr

Operation box version of the program

/

U5

Mechanical Angle with

limit

TYPE

Software no

/

Summary of Contents for GF-1107-147 MH

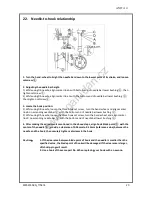

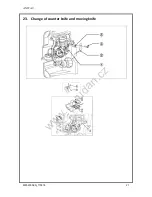

Page 21: ...ANITA MP02300EN_170818 21 23 Change of counter knife and moving knife w w w g a r u d a n c z ...

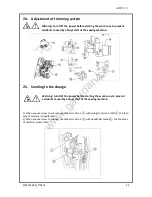

Page 28: ...ANITA MP02300EN_170818 w w w g a r u d a n c z ...

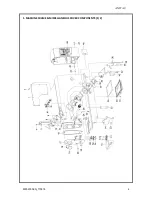

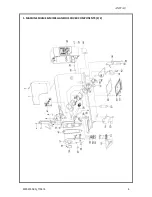

Page 38: ...ANITA MP02300EN_170818 8 2 MAIN SHAFT THREAD TEKE UP COVER COMPONENTS w w w g a r u d a n c z ...

Page 44: ...ANITA MP02300EN_170818 14 4 HANG LIFTER TENSION RELEASE COMPONENTS w w w g a r u d a n c z ...

Page 46: ...ANITA MP02300EN_170818 16 5 THE NEEDLE BAR SWING COMPONENTS w w w g a r u d a n c z ...

Page 48: ...ANITA MP02300EN_170818 18 6 FEED ADJUST MECHANISM COMPONENTS w w w g a r u d a n c z ...

Page 52: ...ANITA MP02300EN_170818 22 8 BOBBIN WINDER COMPONENTS w w w g a r u d a n c z ...

Page 54: ...ANITA MP02300EN_170818 24 9 AUTOMATIC REVERSE FEED COMPONENTS w w w g a r u d a n c z ...

Page 56: ...ANITA MP02300EN_170818 26 10 THREAD STAND COMPONENTS w w w g a r u d a n c z ...

Page 58: ...ANITA MP02300EN_170818 28 11 WIPER COMPONENTS w w w g a r u d a n c z ...

Page 64: ...ANITA MP02300EN_170818 34 13 OIL LUBRICATION COMPONENTS w w w g a r u d a n c z ...

Page 66: ...ANITA MP02300EN_170818 36 14 ACCESSORIE PART COMPONENTS w w w g a r u d a n c z ...

Page 68: ......