ANITA ©

20

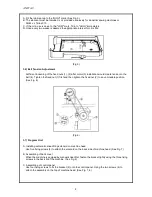

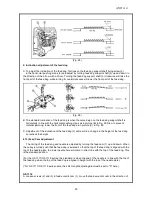

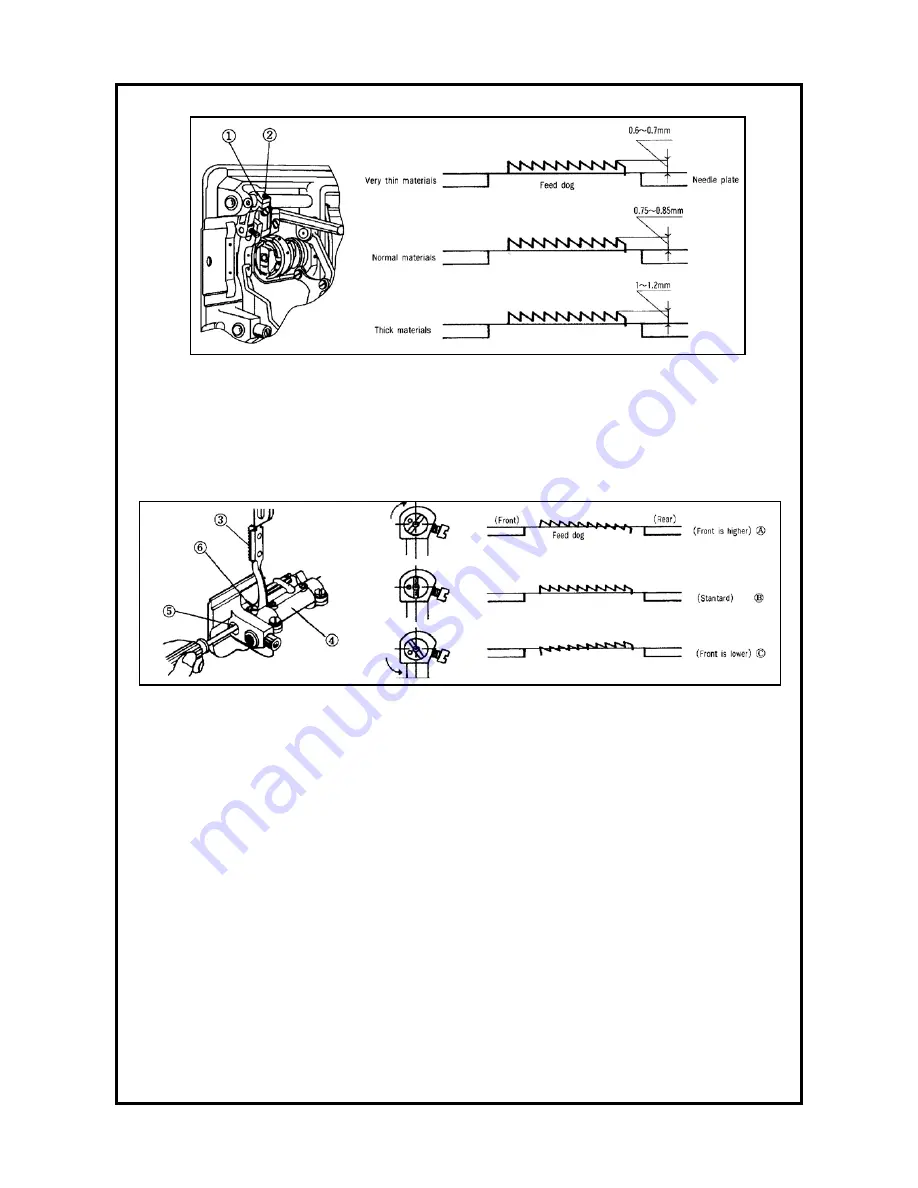

(Fig. 28)

2. Inclination adjustment of the feed dog

A. To adjust the inclination of the feed dog, first loosen the feed dog support shaft fixing screw (6)

in the horizontal pushing crank (4) and adjust by turning feed dog support shaft (5) up and down in

the direction of the arrow with a driver. Turning the feed dog support shaft (5) clockwise will raise the

front part of the feed dog, while turning it counterclockwise will lower the front part of the feed dog.

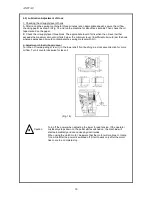

(Fig. 29)

B. The standard inclination of the feed dog is when the carved sign on the feed dog support shaft is

horizontally in line with the horizontal pushing crank as in picture (B) in Fig. 29. Also, to prevent

material jamming, lower the front of the feed dog as in picture (C) in Fig. 29.

C. Adjustment of the inclination of the feed dog (3) will result in a change in the height of the feed dog,

so recheck the height.

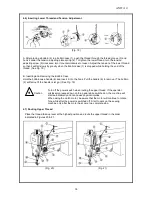

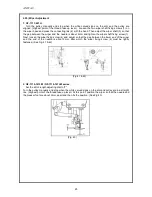

4.13) Feed Cam Adjustment

The timing of the feed dog and needle is adjusted by turning the feed cam (1) up and down. When

the pulley is turned such that the feed dog is lowered so that the top of the feed dog is aligned with the

top of the needle plate, the lower needle hole will come in direct line with the top of the feed dog. This

is the standard position.

(For the GF-1117/GF-1118 series, the standard is when the end of the needle is in line with the top of

the feed dog when the top of the feed dog is aligned in height with the top of the needle plate.)

(*For GF-1117/GF-1118 series users, the stitch length adjusting dial must be set to "0" here.)

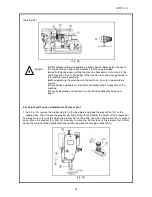

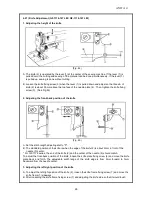

GF-1116

A. Loosen screws (2) and (3) in feed eccetric cam (1), move the feed eccentric cam in the direction of

Summary of Contents for GF-1116 Series

Page 30: ...ANITA 30...