ANITA ©

28

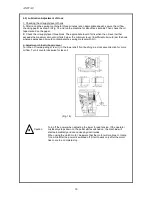

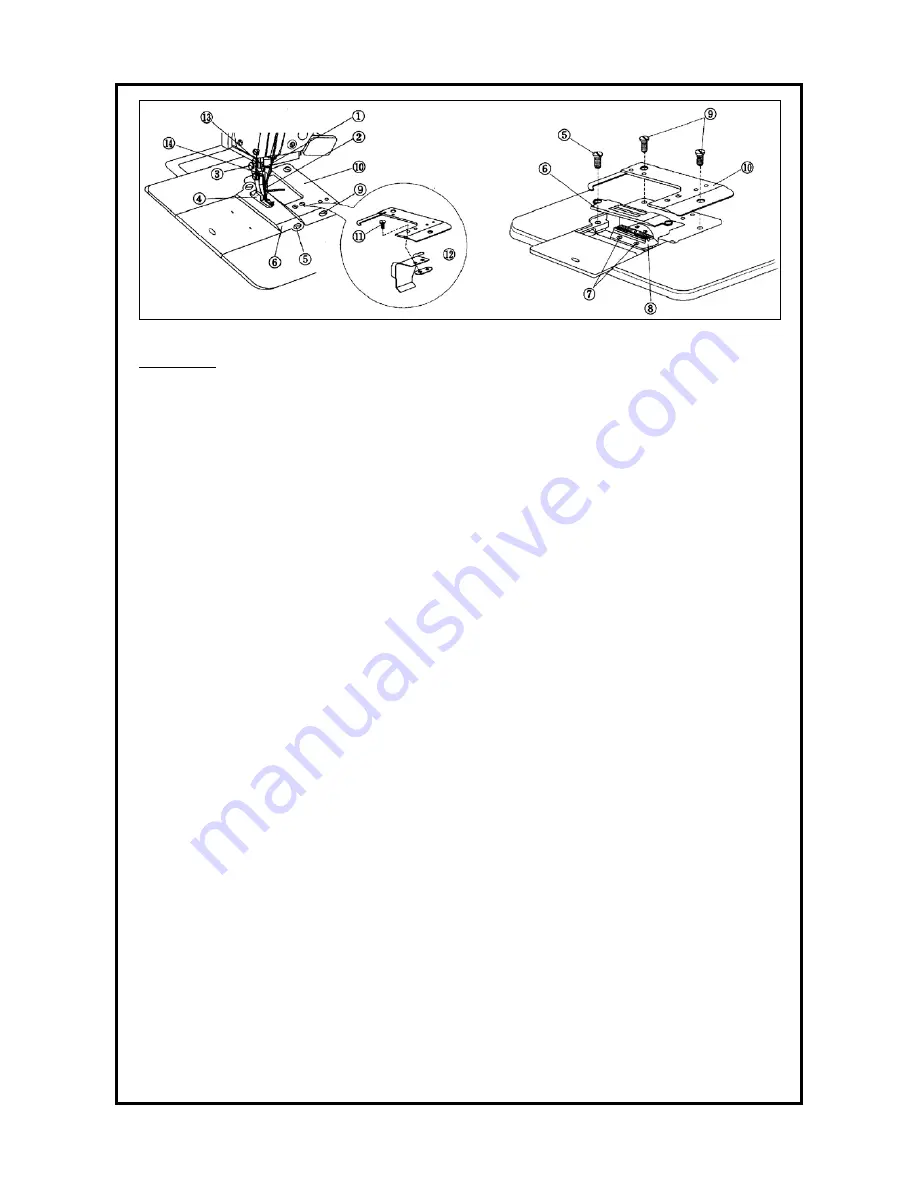

(Fig. 48)

2. Assembly

A. Replace the chip discharge guide (lower) (12) with the one fit for the desired cutting width and fix it

with the auxiliary screw (11) on the auxiliary needle plate (10).

B. Fix the auxiliary needle plate (10) using two fixing screws (9) on the bed.

C. Fix the feed dog (8) using the fixing screw (7).

D. Fix the needle plate (6) on the bed using two fixing screws (5).

* Turn the pulley manually to check whether the space between the feed dog and needle plate during

feed dog movement is equal in all directions. Then, adjust the knife frame to adjust the knife position.

* Move the chip discharge guide (lower) (12) to the left and right so that it is placed 0,05mm from the

knife plate side (6). Then, use the fixing screw (11) to fix the position.

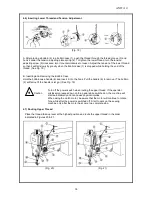

E. Adjust the knife frame so that the pressure of the knife (14) and the needle plate side (6) is

appropriate. Then, tighten the fixing screw. (Refer to the explanation about knife position

adjustment.)

F. Attach the presser foot (4) and tighten the fixing screw (3).

G. Fix the needle (2) with the fixing screw (1).

H. Adjust the knife position adjusting plate (7) to get the desired cutting width and tighten the fixing

screw (8) after adjustment.

* After assembly, refer to the knife position adjustment instructions on page 22 and readjust.

Summary of Contents for GF-1116 Series

Page 30: ...ANITA 30...