9-4

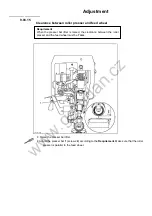

Adjustment

9.03.04

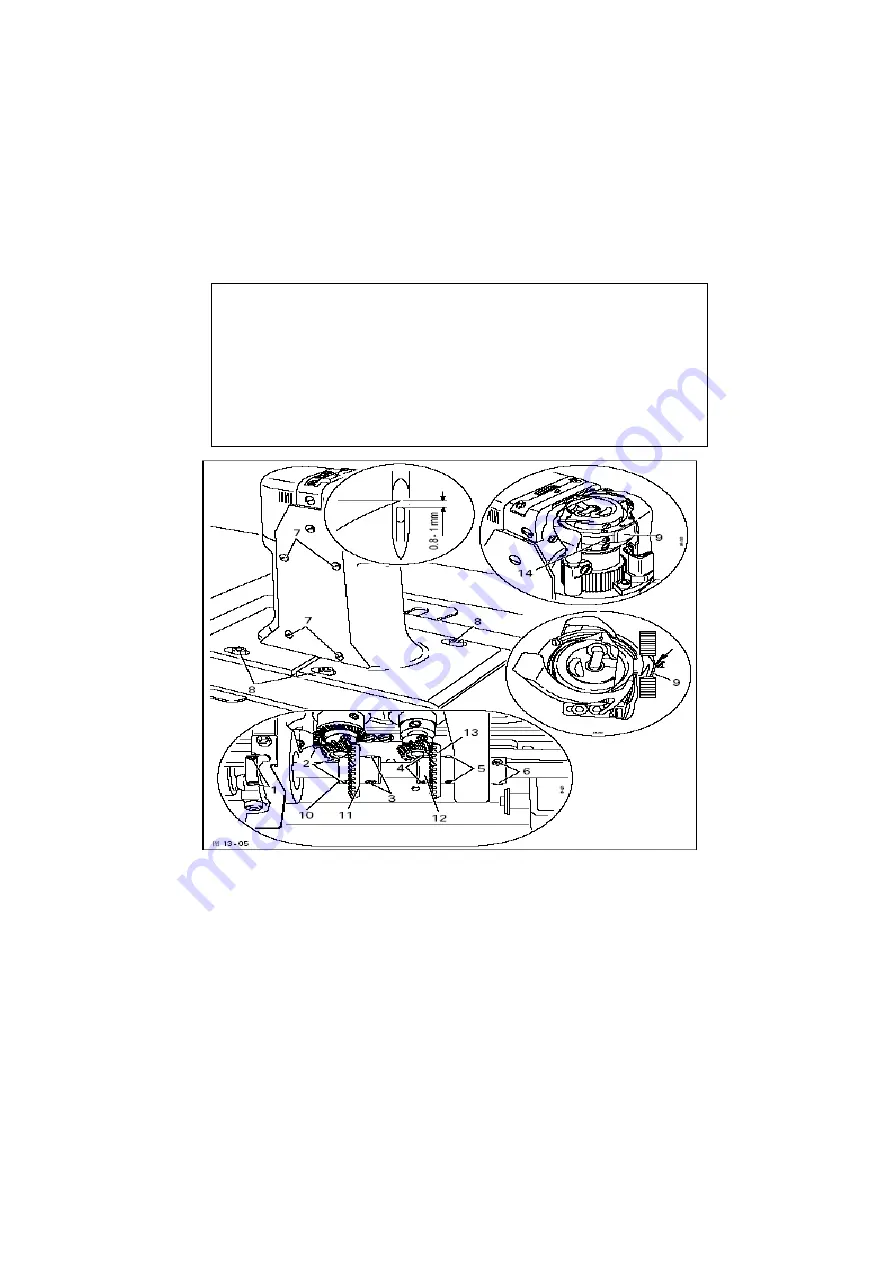

Needle rise, hook clearance, needle height and needle guard on the

GP-724

Requirement

With the needle bar positioned

2.0 mm

after bottom dead centre on

both hooks

:

1. the hook point must be at needle centre with a hook-to-needle

clearance of

0.05

to

0.1 mm

.

2. the top of the needle eye must be

0.8

to

1.0 mm

below the hook

points.

3.

the needle guard

9

must touch the needle lightly.

www.garudan.cz