ANITA ©

MP00006EN_181206

59

13.

TESTS OF MACHINE

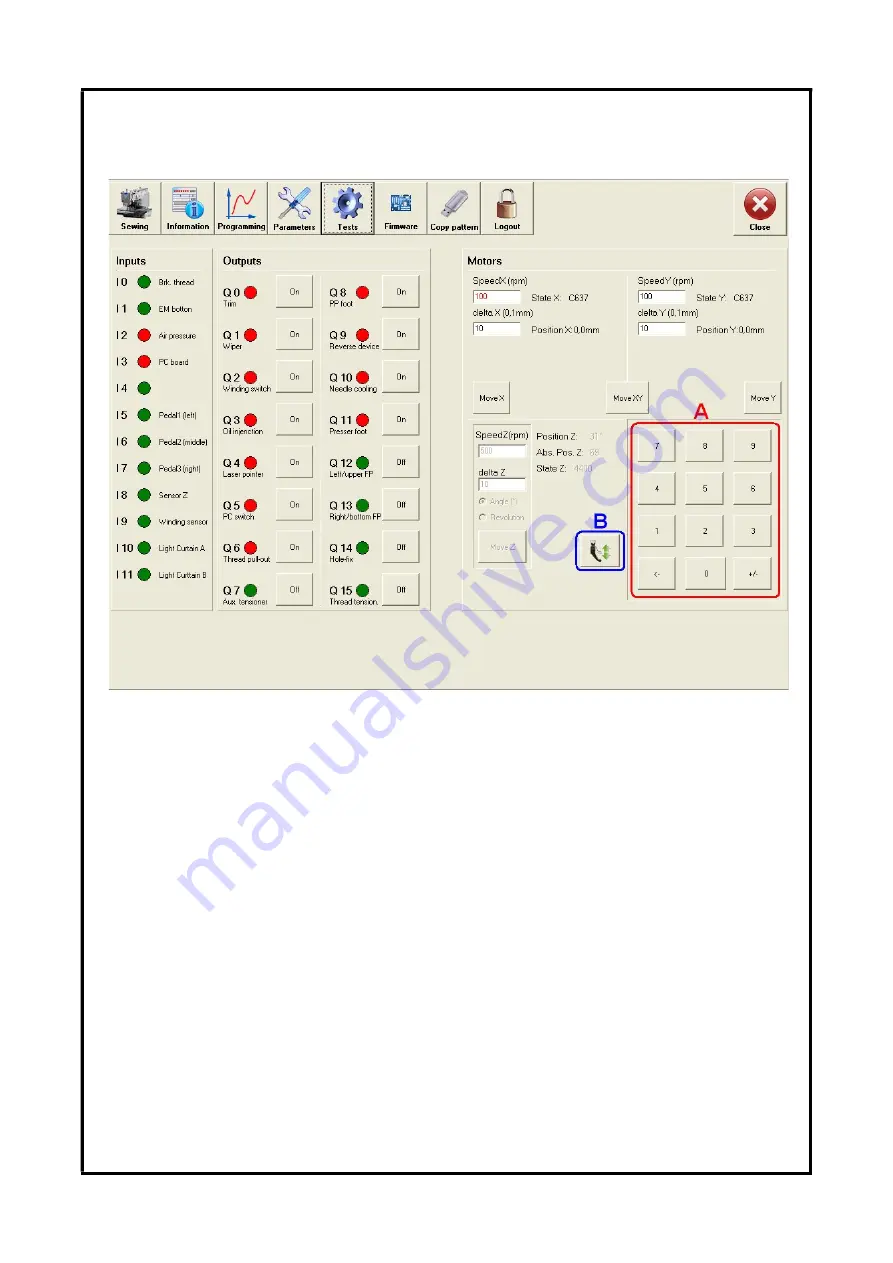

Picture 25: Testing interface

Testing interface is used for identification of errors in machine connection, especially during

assembly or service interventions. Testing interface displays statuses of all inputs, enables control of

all outputs and testing of motor movements. After switching to testing mode machine will

automatically move to sensors of zero position. Functions of individual inputs and outputs are

described in chart 1 and chart 2. Machines with exchange of needles include additional board,

functions of inputs and outputs are described in table 3 and table 4.

For testing of motors part described as

Motors

is used. For testing movements of axis X and Y, it is

necessary to insert required speed to section

Speed

and required distance to section

delta

.

Movement will be activated after pressing button

Move

.

Move X

refers to axis X,

Move Y

refers to

axis Y and button

Move XY

moves both motors simultaneously by required distance.

In needle drive motors you can test only correct running of this motor‘s encoder. During manual

movement of wheel it is possible to check gradual change of motor position in item

Abs.Pos.Z

. This

position change can be observed until second revolving.

Machines GPS/H series can test presser foot by button B. It is not possible test presser foot by output

Q11.

www.garudan.cz

Summary of Contents for GPS/G-10060

Page 69: ......