Multi Gas Clip Simple Plus User’s Manual

UM MGC-S-PLUS v1.00a

Portable gas detectors you can count on

12 of 18

Calibration

The detector can be configured to keep track of regular calibration intervals in a Calibration Log. The interval can be set

using the GCT IR-Link software. When a calibration comes due, or if the last calibration has failed, then the detector’s

display will continually flash “CAL DUE” until the detector has been successfully calibrated. Performing a calibration that

will be recorded in the Calibration Log can be done either automatically (insert the detector into the MGC Simple Clip

Dock), or manually (apply gas according to the Manual Calibration Instructions described below).

Manual Calibration Instructions

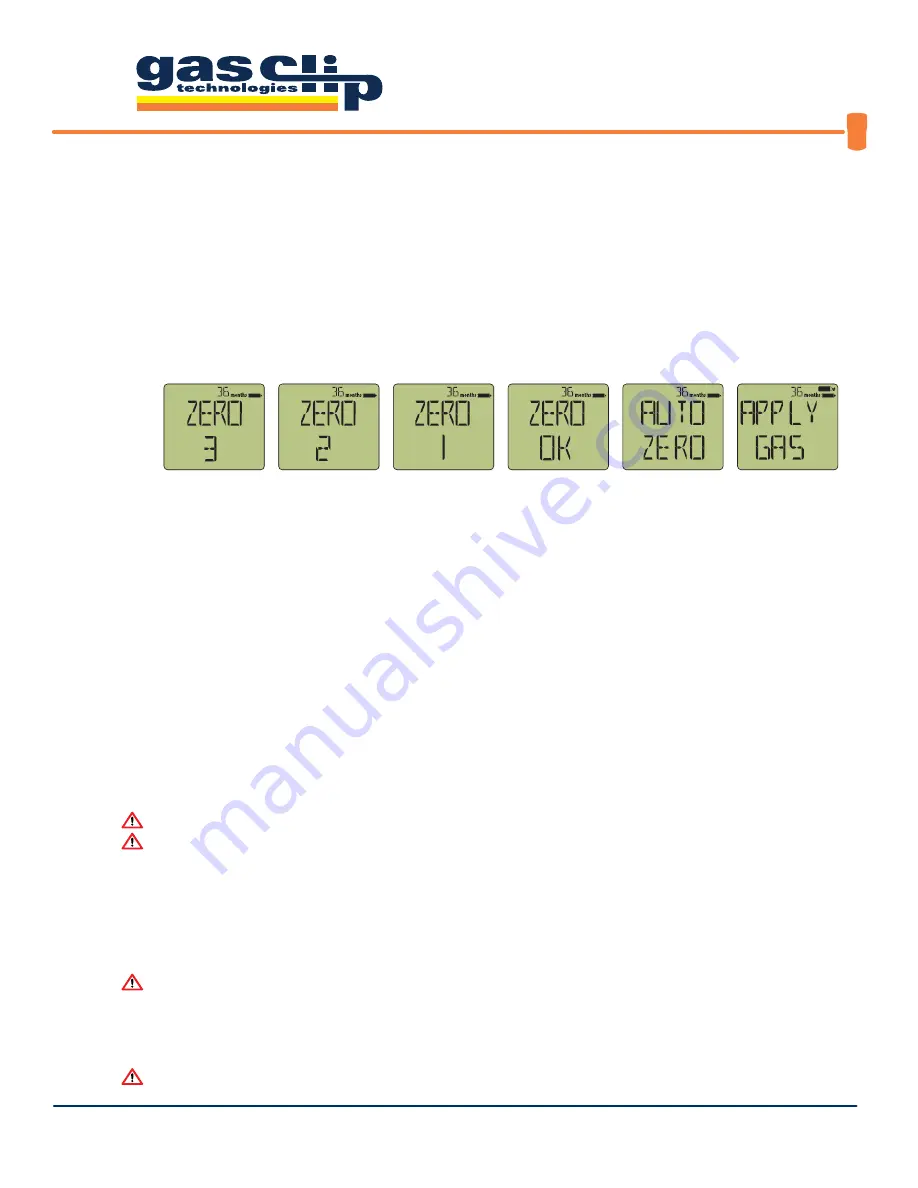

To enter the Manual Calibration mode, continuously hold down the Power/Menu Button. Release the button

when the “ZERO OK” message appears. The detector will first automatically zero the sensors at the current

baseline reading, then the “APPLY GAS” prompt will appear. Display will show:

Once the screen displays “APPLY GAS”, clip the MGC-S Calibration Cap (provided with the detector) into place

over the sensor ports. Apply gas to the detector at a flow rate of 0.5 LPM and do not disturb while calibration

is being performed. Sensor readings will be displayed as the gas is detected and as the detector adjusts the

calibration parameters. Once calibration is complete, the detector will display the next calibration date before

returning to normal (alarming) operation. If a sensor fails to calibrate, the detector will display “ERROR” (an

error message for the failed sensor). Check your gas connections and concentration before attempting a

second calibration.

If a sensor fails to calibrate after a second attempt, contact GCT for assistance

.

Auto Zeroing

To Auto Zero the detector, enter Manual Calibration mode as described above. Once the screen displays "APPLY GAS",

briefly press the Power/Menu Button. The screen will then display "CAL ABORT" followed by the number of days

remaining before the next set calibration date. The detector has been successfully auto zeroed and returns to normal

operation.

Auto Zero the detector only in a known clean air environment .

DO NOT Auto Zero in temperatures above or below the specified range of 0°C to 40°C .

Retest

To attempt recovery from sensor "Err", continuously hold down the Power/Menu Button during count downs. Release

the button when the "RETEST OK" message appears. The detector will retest sensors and auto zero the detector. Auto

Zeroing precautions apply.

Under no circumstances should a detector displaying "Err" be used .

Storage

Store the detector in a safe, dry place between 32°F and 77°F (0°C and 25°C).

Review the warranty period and the “Activate before . . ." date that is printed on the product box label .

Release

Power/Menu Button