EXHAUST SYSTEM

The exhaust and the muffler reduce the noise and send gases away

from the rider.

If the exhaust is badly damaged, dented, cracked or rusted, replace

it with a new one. Replace the muffler fibre if the exhaust noise

becomes too loud or if the engine performance drops.

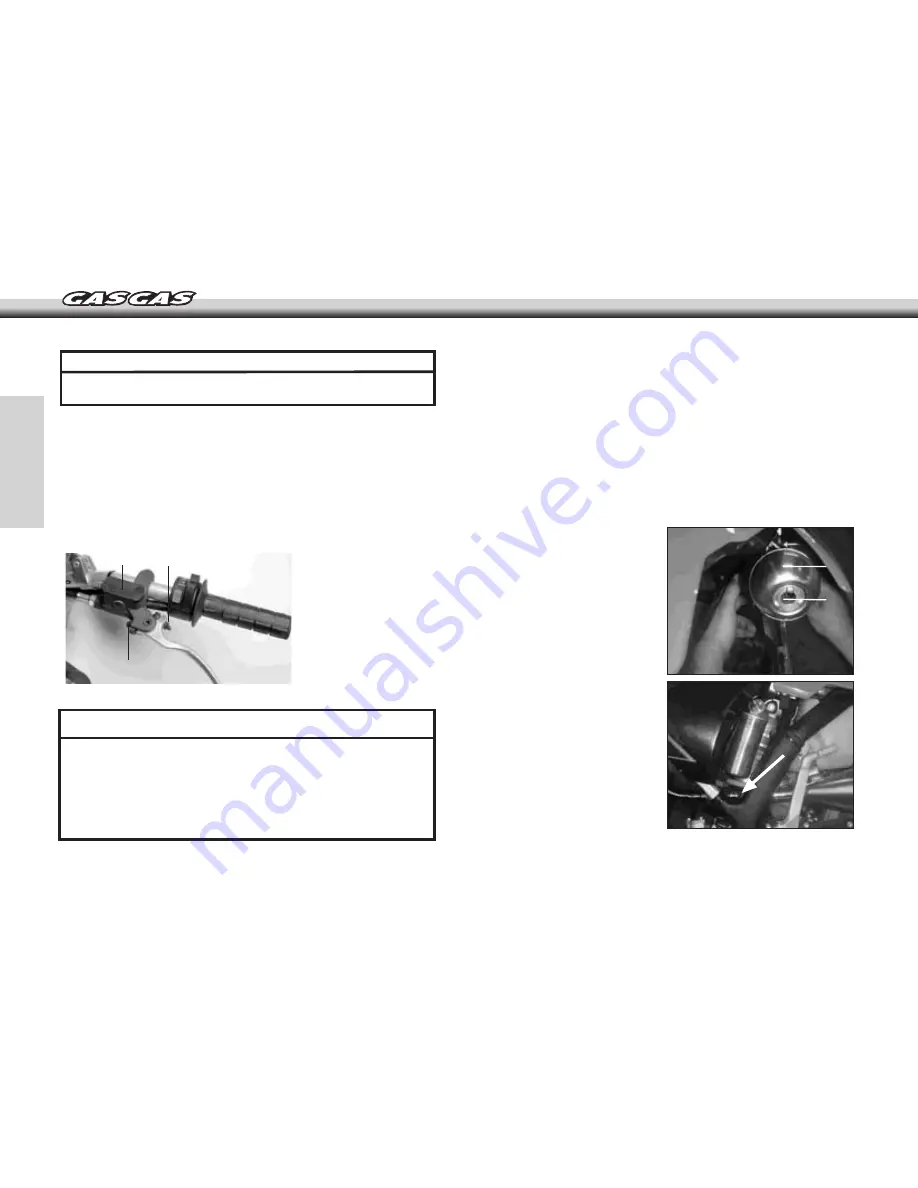

Muffler replacement

- Remove the retaining screws

(A)

of the muffler

(B)

and

remove the muffler towards

the rear.

- Separate the silencer from

the joint -arrow-.

- Replace the muffler and reinstall the assembly.

WARNING

Riding with a damaged throttle cable could be dangerous.

CLUTCH

The clutch lever should have a maximum play of 3 mm. This margin

increases with the wear on the clutch plate.

To adjust, proceed as follows:

- Use bolt

A

to adjust the lever’s range of movement to the rider’s

convenience.

- Adjust the play of the lever using bolt

B

.

WARNING

- Maintain the clutch lever with the play shown, otherwise the

performance and useful life of the clutch may be adversely affected.

- The EC 2006 model uses mineral oil GRO ULTRA 5 for the clutch

hydraulic circuit.

- Tank

C

must not be filled with liquid from the models of previous

years.

-26-

(C)

(A)

(B)

- Remove the retaining screws of the right side number-posting cover .

(A)

(B)

Summary of Contents for ENDUCROSS EC - 2007

Page 2: ......

Page 3: ...ENGLISH USER MANUAL USER MANUAL enducross EC 07 enducross EC 07...

Page 4: ......