Owner's Manual

-64-

Suspension setting

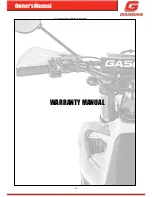

rear shock absorber (Kyb).

• Rebound (1) - located at the bottom of the shock absorber.

• Low speed compression (2) - located at the top of the shock absorber (screw).

• High speed of compression 17mm. - located at the top of the shock absorber (4)

• standard spring preload (3) - 248 mm, adjustable between 243 and 255 mm

between its support planes.

-k spring /250/300cc: 52n/m - ideal rider weight 75-85 kg.

1

2

3

4

standard: 260 mm

Range: 243-255 mm

setting length: 248 mm

s

Summary of Contents for Enduro 2T 250 2018

Page 1: ......

Page 5: ...Owner s Manual 5...

Page 6: ...Owner s Manual 6 This page has been left blank intentionally...

Page 7: ...Owner s Manual 7 General information...

Page 16: ...Owner s Manual 16...

Page 17: ...Owner s Manual 17 Electric diagram for 250 300cc models...

Page 18: ...Owner s Manual 18...

Page 21: ...Owner s Manual 21 Table of tightening torques 1 2 3 4 5 6 7 8 9...

Page 25: ...Owner s Manual 25...

Page 26: ...Owner s Manual 26 This page has been left blank intentionally Operating instructions...

Page 35: ...Owner s Manual 35 Maintenance...

Page 58: ...Owner s Manual 58 This page has been left blank intentionally Settings...

Page 68: ...Owner s Manual 68 This page has been left blank intentionally Troubleshooting...

Page 73: ...Owner s Manual 73...

Page 74: ...Owner s Manual 74 This page has been left blank intentionally Warranty manual...

Page 77: ......