-

27

-

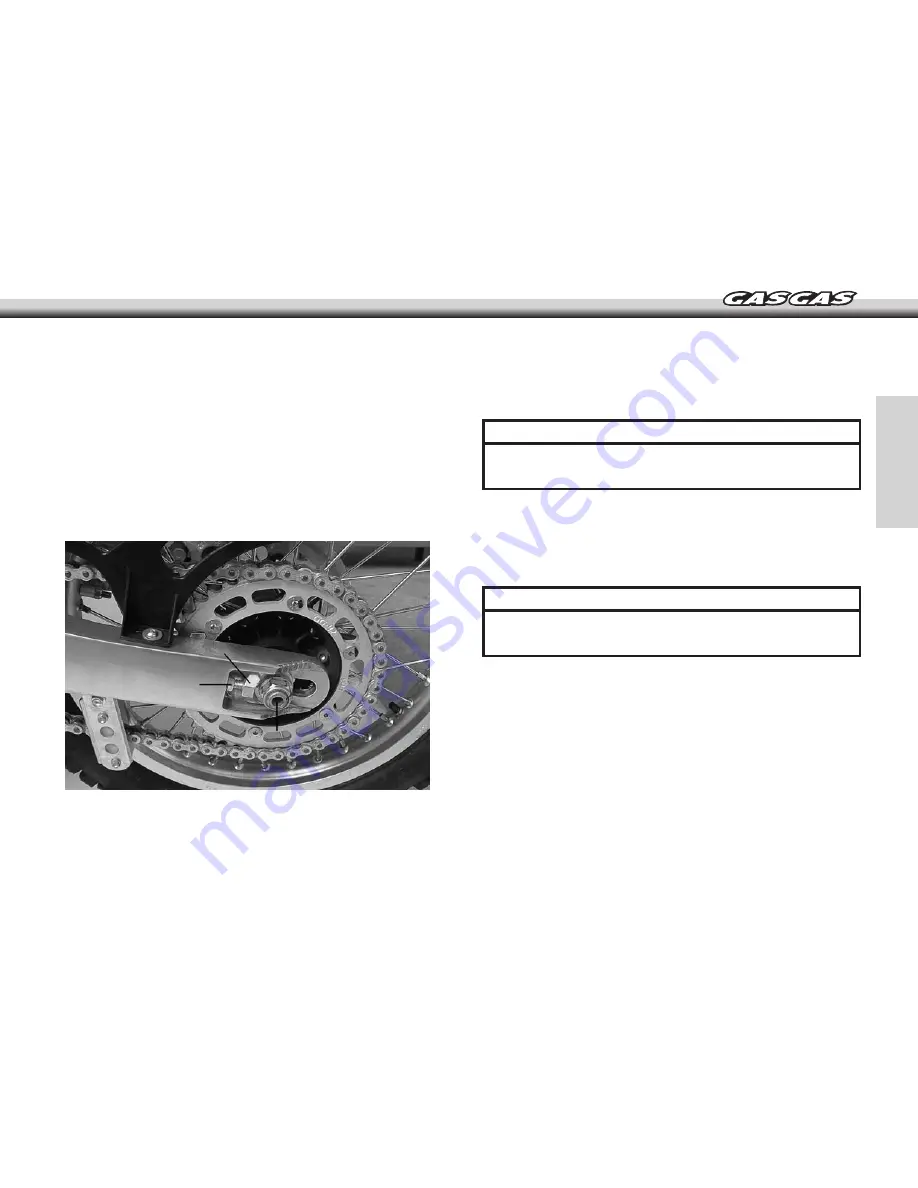

In addition to checking the slack, rotate the rear wheel to inspect

the drive chain and sprockets for damaged rollers, loose pins and

links, unevenly or excessively worn and damaged teeth.

Tension adjustment

-Loosen the rear axle nut.

- Turn the nuts on the chain adjusting bolts evenly until there is

30-50 mm of space between the chain and the rocker arm. To keep

the chain and wheel aligned, the adjustment on the left of the chain

should be equal to that on the right.

(A). Rear axle.

(B). Adjustment nut.

(C). Chain adjustment.

NOTE

Wheel alignment can also be checked using the straightedge

or string method.

WARNING

Misalignment of the wheel will result in abnormal wear and may

result in an unsafe riding condition.

- Tighten the chain adjustment nuts.

- Tighten the axle nut to 98 N-m.

- Rotate the wheel, measure the chain slack again at the tightest

position, and readjust if necessary.

WARNING

If the rear axle nut is not securely tightened this may lead to unsafe

riding conditions.

Drive chain, chain guide, chain slide, and rear sprocket

When the chain has worn so much that it is more than 2% longer

than when new, it is no longer safe for use and should be replaced.

Whenever the chain is replaced, inspect both the engine pinion and

rear sprocket, and replace them if necessary. Worn teeth will cause

the chain to wear more quickly.

(C)

(B)

(A)