Owner's Manual

-29-

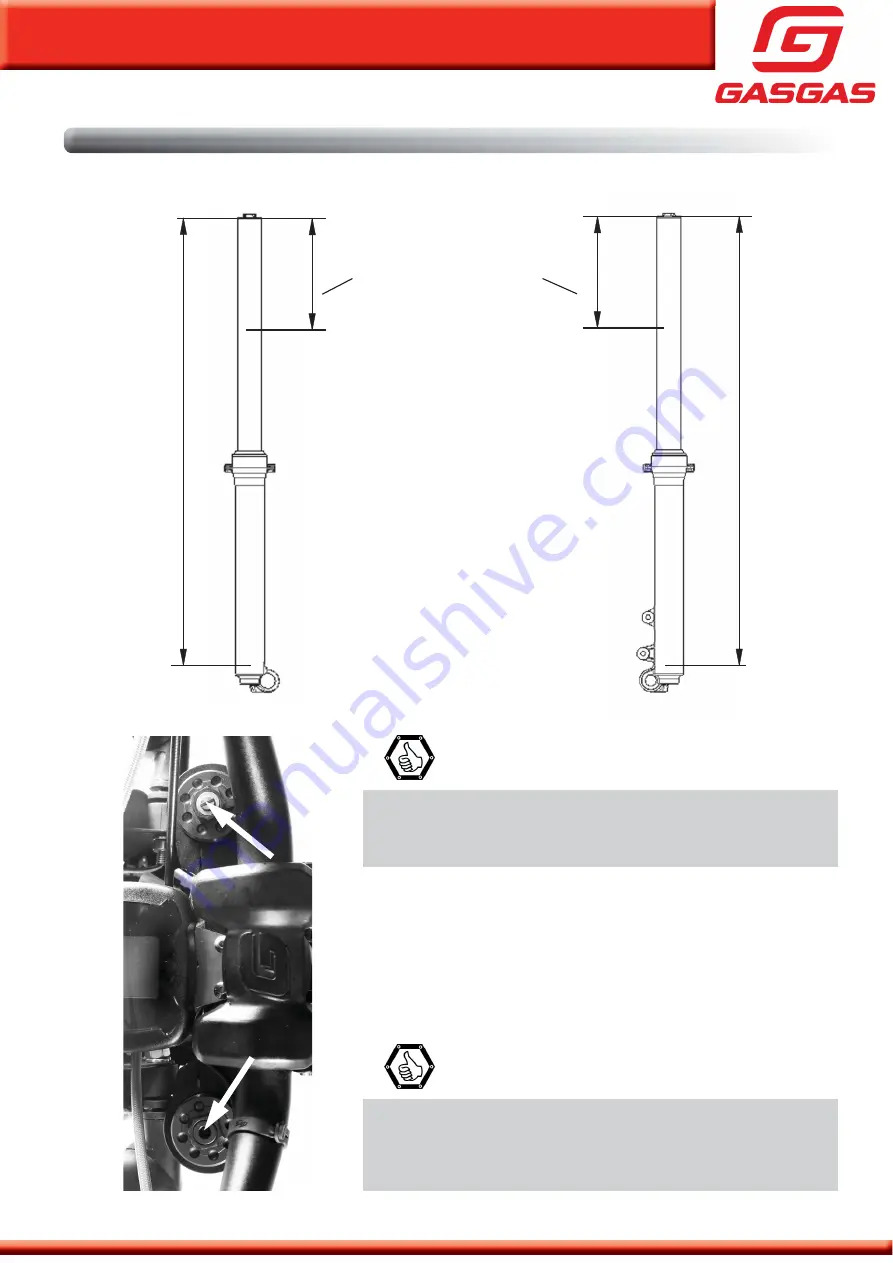

Front suspension

5

8

0

m

m

.

7

5

m

m

.

1

3

0

m

m

.

5

8

0

m

m

.

For an average weight of 75 kg, we

preload the spring by 5 turns

* Measurement without spring and

with compressed hydraulic rod

* Air chamber level

A

B

The front suspension is adjusted manually.

(A)

Right (hydraulic extension)

(B)

Le

! (spring preloading)

In the lower part of the suspension, we have the following adjustments:

right (hydraulic compression)

le! (hydraulic brake end of travel)

Summary of Contents for TXT RACING 125CC 2020

Page 1: ......

Page 41: ...Owner s Manual 41 Approved electrical system...

Page 42: ...Owner s Manual 42 Ignition electrical system...

Page 51: ......