-15-

8. MAINTENANCE

This machine requires virtually no maintenance. Even so, there are a few details that must be taken

into consideration.

1.

Periodically check the condition of all moving parts: retainers, gears and bearings.

2.

Periodically check the condition of the extractor slice thread (Pos. 12, overview).

If it is necessary to change the thread, to remove it, bend the slice, then you can easily remove the

thread and replace it with a new one.

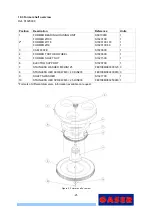

Image 19, Folding to remove thread

Image 20, removing thread

3.

Periodically check the condition of the gear motor.

4.

Periodically check the condition of the safety elements.

5.

Periodically check the general condition of the machine.