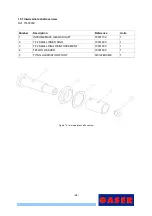

10.7 Intermediate shaft overview

Ref. 77600000

Number

Description

Reference

Units

1

INTERMEDIATE GEARS SHAFT

70091700

1

2

T-72 SMALL INNER RING

70091600

1

3

T-72 SMALL RING REINFORCEMENT

70091800

1

4

TEFLON WASHER

70091900

1

5

TYING LUBRICATION POINT

SI0122EHCM8

1

Figure 10. Intermediate shaft overview

-24-

Summary of Contents for T-70

Page 1: ...SEMIAUTOMATIC TYING MACHINE Mod T 70...

Page 17: ...Figure 2 General overview 2 Figure 3 General overview 3 17...

Page 18: ...Figure 4 Pneumatic elements 18...

Page 27: ...Pneumatic diagram 1 27...

Page 28: ...28...