5

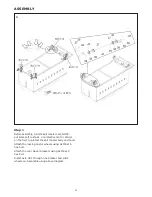

GENERAL ASSEMBLY

Assembly will require 2 people due to the Spit

Roaster size.

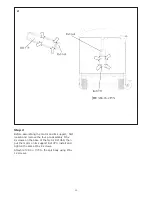

Connecting & Disconnecting

to Gas Source

Familiarise yourself with the general information and

safety guidelines located at the front of this manual.

Check

1. Gas cylinder is

filled.

A sloshing sound will be

heard when shaken.

2. The burner control is in the ‘OFF’ position

Connecting

1. Ensure cylinder valve is in its full off position.

2. Check for any damage to either the cylinder

connection or the hose. NEVER attempt to use

damaged equipment.

3. When connecting the hose to the cylinder tighten

the nut to a positive stop by hand or spanner.

4. Open cylinder valve fully. If a leak can be heard

at either end of the hose turn cylinder off and

tighten joint. Wait 5 minutes before re-testing

and use a soapy water solution to check the

joint. If bubbles appear the connection will need

to be re-tightened.

Disconnecting

1. Ensure the burner control is in the

‘OFF’ position.

2. Ensure gas cylinder is in the full off position.

3. Detach the hose from cylinder.

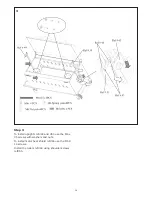

LIGHTING PROCEDURE

Burner Operation

& Ignition System Check

1. With cylinder valve in OFF position press the

electronic igniter button. Check for sparking to

the burners.

2. Lift hood, remove the 4 stainless steel trays,

leave hood open until both burners are fully lit.

3. If spark is not evident at the burner ignition

point, check that the ignition lead is

firmly

attached to the control and sparker tip.

4. With sparking established, turn cylinder valve

ON. Push and turn a control knob on either side

of the ignitor to HIGH and press the ignitor

button.

5. If burner fails to light after several attempts

turn off the gas supply at cylinder and inspect

for any obstructions to the gas

flo

w.

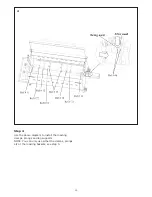

6. Both burners will need to be lit following steps

1-5.

If re–ignition is necessary while the gas spit

roaster is still hot, you must wait for a minimum of

5 minutes before commencing to re–ignite

(this allows accumulated gas fumes to clear).

After Use

Turn the gas cylinder valve off and wait for the

flame

to go out. Then turn the appliance control

valve off.

IMPORTANT

• Remove all packing and transit protection

before assembly.

•

CAUTION:

Ensure no packing material is

left in spit roaster before lighting. Remove

all plastic protection, usually blue

film

before

assembly and use.

• Before connecting and disconnecting spit

roaster to gas source, make sure burner

controls are in ‘OFF’ position.

•

CAUTION:

When the spit roaster is not in use,

the gas must be turned off at the cylinder.

• Check that the seals between the appliance

and the gas cylinder are in place and in good

condition before connecting the gas cylinder.

• Do not use this appliance if it has damaged or

worn seals.

• The appliance control knob must be in the ‘OFF’

position before opening the cylinder valve.

• If for some reason, ignitor fails to produce a

spark at the electrode, spit roaster can be lit

by a long spit roaster match. With hood open

use a lighted match from top. Push and turn a

control knob to HIGH. Light the other burner

in the same way.

• Check performance of burner prior to installing

spit roaster rack.

• Do not smoke when attempting to

ignite spit roaster.

• Never use volcanic rock, heat beads

or other material.

• Always use protective gloves when handling

hot components.

Summary of Contents for GSB300

Page 10: ...10 EXPLODED DIAGRAM ...